A kind of diesel energy-saving detergent synergist and preparation method thereof

A synergist and cleaning technology, used in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of poor start-up, poor miscibility, strong corrosiveness, etc., to reduce the amount of carbon deposition and coking, and achieve good stability. , good low temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Materials: See Table 1

[0026] step:

[0027] (1) Set the temperature of the stirring tank to 30°C, add polyetheramine, methanol, and polyoxymethylene dimethyl ether to the stirring tank in sequence, mix and stir for 30 minutes, and let stand for 50 minutes to obtain a mixed solution A;

[0028] (2) Add n-butanol, butanone oxime and polyisobutylene succinimide to the stirring tank in turn, mix and stir with the mixed solution A for 30 minutes to obtain the mixed solution B;

[0029] (3) Add the remaining materials into the stirring tank, mix with the mixed solution B and stir for 30 minutes, and let it stand for 20 hours to obtain the product.

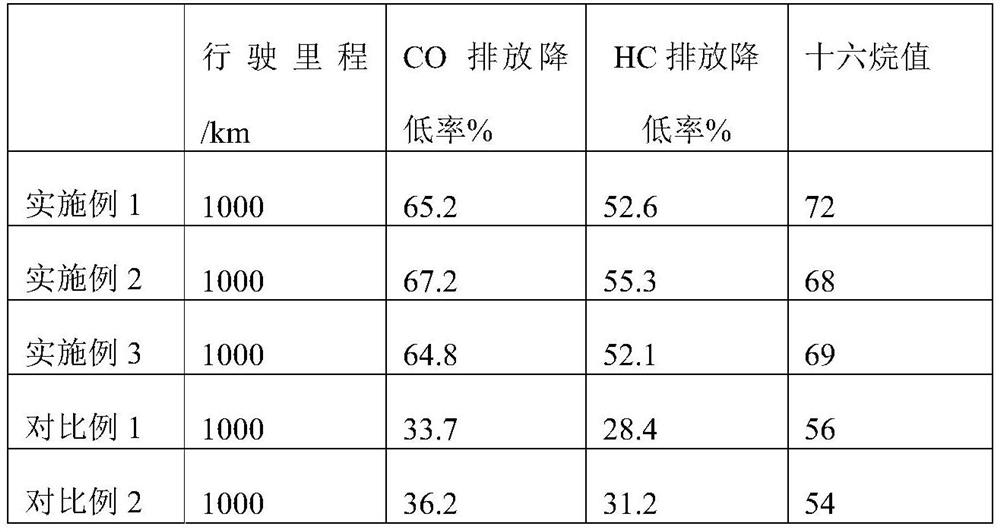

[0030] Table 1

[0031] Material type (wt%) Example 1 Example 2 Example 3 Comparative example 1 Comparative example 2 Methanol 20 25 20 30 20 Butanol 15 20 10 15 10 n-octanol 15 10 10 15 10 Hexamethylbutyl ether 10 13 18 10 18 Butanone oxime 15 10 11 10 11 ...

Embodiment 2

[0033] Materials: See Table 1

[0034] (1) Set the temperature of the stirring tank to 35°C, add polyetheramine, methanol, and polyoxymethylene dimethyl ether into the stirring tank in sequence, mix and stir for 40 minutes, and let stand for 60 minutes to obtain a mixed solution A;

[0035] (2) Add n-butanol, butanone oxime and polyisobutylene succinimide to the stirring tank in turn, mix and stir with the mixed solution A for 40 minutes to obtain the mixed solution B;

[0036] (3) Add the remaining materials into the stirring tank, mix with the mixed solution B and stir for 40 minutes, and let it stand for 18 hours to obtain the product.

Embodiment 3

[0038] Materials: See Table 1

[0039] (1) Set the temperature of the stirring tank to 40°C, add polyetheramine, methanol, and polyoxymethylene dimethyl ether into the stirring tank in sequence, mix and stir for 50 minutes, and let stand for 50 minutes to obtain a mixed solution A;

[0040] (2) Add n-butanol, butanone oxime and polyisobutylene succinimide to the stirring tank in turn and mix and stir with the mixed solution A for 50 minutes to obtain the mixed solution B;

[0041] (3) Add the remaining materials into the stirring tank, mix with the mixed solution B and stir for 50 minutes, and let it stand for 22 hours to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com