Ultrathin polyethylene microporous breathable film and preparation method thereof

A polyethylene and breathable film technology, used in chemical instruments and methods, flat products, other household appliances, etc., can solve the problems of low gram weight, leakage of inorganic calcium carbonate particles, etc., and achieve small dimensional shrinkage and excellent physical and chemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The melt index is 0.5g / min, and the density is: 0.925g / cm 3 Bimodal molecular weight distribution polyethylene 20kg, particle diameter is 1.0 μ m calcium carbonate particles 70kg, silver ion antibacterial masterbatch 5kg, γ-(2,3-epoxypropoxy) propyltrimethoxysilane 3kg, antioxidant 1kg, 1 kg of polyphthalamide, dried and dehumidified, mixed uniformly, granulated by a twin-screw extruder, pelletized by water-cooling and low temperature, and used as a 75% calcium carbonate masterbatch for future use.

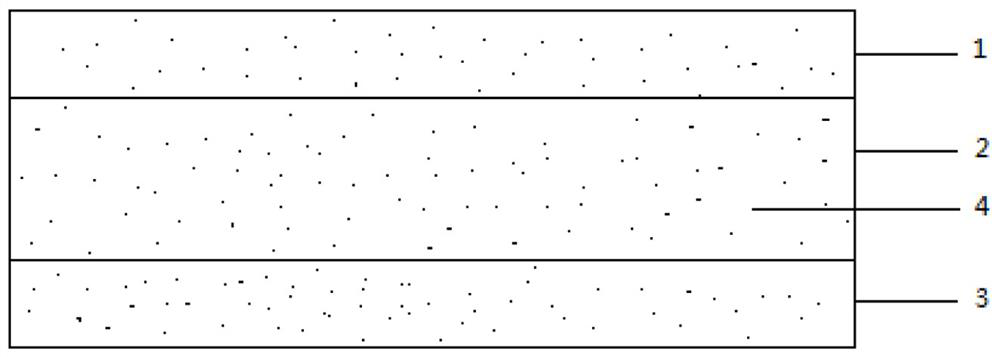

[0038] Such as figure 1As shown, the above-mentioned calcium carbonate masterbatch and resin pellets are mixed and dried using the following ratio to ensure that the moisture content is ≤ 300PPM. The screw machine hopper is added separately.

[0039] Inner layer: 50kg of calcium carbonate masterbatch, 25kg of linear low-density polyethylene, 23kg of ethylene-octene copolymerized polyethylene, and 2kg of polyphthalamide.

[0040] Middle layer: 70kg of calcium carbonate ma...

Embodiment 2

[0047] The melt index is 0.8g / min, the density is: 0.925g / cm 3 Bimodal molecular weight distribution polyethylene 20kg, particle size 1.0μm calcium carbonate particles 70kg, silver ion antibacterial masterbatch 5kg, 3(phenylamino)propyltrimethoxysilane 3kg, antioxidant 1kg, polyphthalamide 1kg , mixed evenly after drying and dehumidification, granulated by a twin-screw extruder, water-cooled and low-temperature granulated, and used as a 75% calcium carbonate masterbatch for later use.

[0048] Such as figure 1 As shown, the above-mentioned calcium carbonate masterbatch and resin pellets are mixed and dried using the following ratio to ensure that the moisture content is ≤ 300PPM. The screw machine hopper is added separately.

[0049] Inner layer: 50kg of calcium carbonate masterbatch, 28kg of linear low-density polyethylene, 20kg of ethylene-octene copolymerized polyethylene, and 2kg of polyphthalamide by weight.

[0050] Middle layer: 70kg of calcium carbonate masterbatch,...

Embodiment 3

[0057] The melt index is 1.5g / min, the density is: 0.93g / cm 3 Bimodal molecular weight distribution polyethylene 20kg, particle size 1.2μm lipophilic active calcium carbonate particles (lipophilic calcium carbonate obtained by surface modification of stearic acid calcium carbonate) 70kg, silver ion antibacterial masterbatch 5kg, glycidyl acrylate 3kg , 1 kg of antioxidant, 1 kg of polyphthalamide, dried and dehumidified, mixed evenly, granulated by twin-screw extruder, water-cooled and low-temperature pelletized, and used as a 75% calcium carbonate masterbatch for subsequent use.

[0058] Such as figure 1 As shown, the above-mentioned calcium carbonate masterbatch and resin pellets are mixed and dried using the following ratio to ensure that the moisture content is ≤ 300PPM. The screw machine hopper is added separately.

[0059] Inner layer: 50kg of calcium carbonate masterbatch, 30kg of linear low-density polyethylene, 18kg of ethylene-octene copolymerized polyethylene, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com