Layered graphite composite bipolar plate and preparation method thereof

A layered, bipolar plate technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, fuel cells, etc., can solve the problem of reducing the forming thickness of graphite composite bipolar plate and precision forming flow channel, reducing the Problems such as graphite composite bipolar plate molding thickness and precision molding flow channel can alleviate low molding reliability, facilitate mass production, and improve bending strength and air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

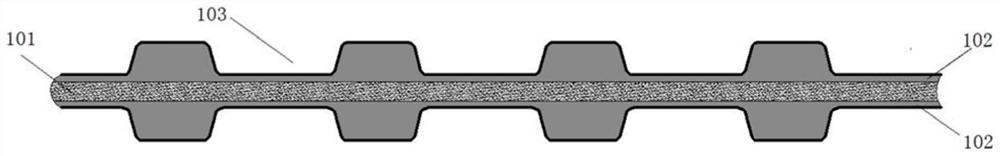

[0068] A method for preparing a layered graphite composite bipolar plate, comprising the following steps:

[0069] S1: Preparation of thermoplastic resin / graphite composite sheet by roll forming;

[0070] S2: preparing a masterbatch of thermosetting resin / graphite composite material;

[0071] S3: Fill the drying mold with the masterbatch of thermosetting resin / graphite composite material, thermoplastic resin / graphite composite material plate and masterbatch of thermosetting resin / graphite composite material in sequence, and perform drying treatment;

[0072] S4: put the dried material in step S3 together with the drying mold into a hot molding mold, pressurize and heat to shape, and obtain a layered graphite composite bipolar plate after cooling.

[0073] Preferably step S1 comprises the following process:

[0074] S11: Dry blend thermoplastic resin and graphite powder, mix evenly and then dry to prepare masterbatch A:

[0075] S12: Preheat masterbatch A in a preheating box...

Embodiment 1

[0093] Prepare a layered graphite composite bipolar plate, comprising the following steps:

[0094] (1) Dry-mix fluorinated ethylene-propylene (FEP) with an average particle size of 8 μm and flake graphite with an average particle size of 50 μm through a plastic kneader for 2 hours, and the mass ratio of FEP to flake graphite is 4:6. Then the mixed masterbatch was put into a vacuum drying oven, and dried at 70° C. for 2 hours to obtain masterbatch A.

[0095] (2) The masterbatch A is dropped into the preheating box 203 by the vibrating feeder 201, such as image 3 As shown, the preheating temperature is 360°C.

[0096] (3) The transfer mechanism 208 transfers the masterbatch A to the rough roll, and rough rolls it into a plate with a thickness of 2.0 mm. The last 7 rounds of finish rolling process the thickness to 1.5mm, 1.0mm, 0.7mm, 0.5mm, 0.4mm, 0.35mm, 0.3mm in sequence. The rough roll and finish roll are heated during operation to keep the surface temperature of the ro...

Embodiment 2

[0103] Prepare a layered graphite composite bipolar plate, comprising the following steps:

[0104] (1) Based on Example 1, complete the production of the middle layer.

[0105] (2) Preheat liquid epoxy resin (E-44) and curing agent phthalic anhydride (HHPA) to 110°C respectively, and keep for 2 minutes.

[0106] (3) Weighing and taking epoxy resin and HHPA mass ratio is 5:4, and at the same temperature, pour into a beaker and stir for 5min, take 0.5% benzylmethyldimethylamine of epoxy resin quality in the stirring process as Accelerators are added to epoxy resins.

[0107] (4) Add graphite flakes to the homogeneously mixed resin, with a particle size of 60 μm to 80 μm. The mass ratio of resin to graphite mixed is 2:8. Maintain a constant temperature of 110°C, and mechanically stir for 20 minutes until uniformly mixed to obtain masterbatch B.

[0108] (5) Add masterbatch B, intermediate layer 101, and masterbatch B to the drying mold in sequence. The filling thickness of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com