Environment-friendly high-performance recycled plastic granule and preparation process thereof

A high-performance technology of recycled plastic particles, applied in the field of plastic processing, can solve the problems affecting the quality, agglomeration and poor compatibility of recycled plastic products in the chain extension reaction, so as to improve the agglomeration, improve compatibility, and promote uniform dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

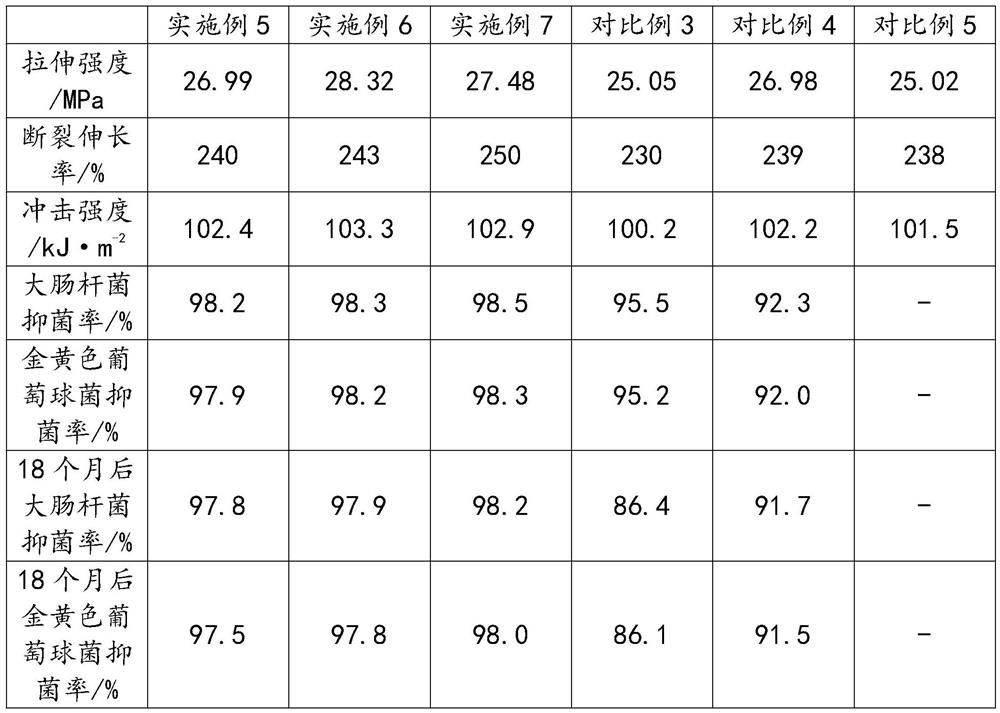

Examples

preparation example Construction

[0047] The preparation process of the environmentally friendly high-performance recycled plastic particles includes the following steps:

[0048] The first step is to soak the waste polyethylene plastic in clean water, then rinse it with ethanol and acetone for 2-3 times, then rinse it with water for 2-3 times, dry it so that the moisture content is less than 0.05%, and crush it through 100 mesh Sieve to obtain pretreated waste polyethylene plastics;

[0049] The second step, add pretreated waste polyethylene, modified polyethylene, modified chitosan, crosslinking agent and additives into the double rotor continuous mixer, the rotor speed is 160-200r / min, mixing for 20-30min, and then Add the reinforcing agent and continue mixing for 8-10 minutes to obtain the premix;

[0050] In the third step, the premix obtained in the second step is directly heated and fed into the extrusion granulation equipment, and the recycled plastic granules are obtained through exhausting, pelletiz...

Embodiment 1

[0052] Modified chitosan is prepared by the following method:

[0053] S1. Weigh chitosan powder and add it to distilled water, first ultrasonic for 10min, then stir at a constant speed of 150r / min, and slowly add dimethyloctadecyl[3-(trimethoxysilyl) Propyl]ammonium chloride, after dropping, stirred at a constant speed of 150r / min for 22h at room temperature, washed the final product with distilled water and methanol for 3 times, and finally put the product into a vacuum drying oven at 60°C for 20h to obtain grafted chitosan;

[0054] Wherein, the ratio of the consumption of chitosan powder, distilled water, dimethyl octadecyl [3-(trimethoxysilyl) propyl] ammonium chloride is 1g: 110mL: 35mL;

[0055] S2. Disperse the grafted chitosan in chloroform, ultrasonicate for 8 minutes, then add 4g sodium nonylphenol polyoxyethylene ether sulfate, stir magnetically at room temperature for 22h, then add 20mL distilled water to the reaction system and continue magnetically stirring for...

Embodiment 2

[0058] Modified chitosan is prepared by the following method:

[0059] S1. Weigh chitosan powder and add it to distilled water, first ultrasonic for 15min, then stir at a constant speed of 150r / min, and slowly add dimethyloctadecyl[3-(trimethoxysilyl) Propyl]ammonium chloride, after dropping, stirred at a constant speed of 150r / min for 24h at room temperature, washed the final product with distilled water and methanol for 4 times, and finally put the product into a vacuum drying oven at 60°C for 24h to obtain grafted chitosan;

[0060] Wherein, the ratio of the consumption of chitosan powder, distilled water, dimethyloctadecyl [3-(trimethoxysilyl) propyl] ammonium chloride is 1g: 120mL: 40mL;

[0061] S2. Disperse the grafted chitosan in chloroform, first ultrasonic for 10min, then add 4g sodium nonylphenol polyoxyethylene ether sulfate, stir magnetically at room temperature for 24h, then add 20mL distilled water to the reaction system and continue magnetically stirring for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com