Porous ceramic as well as preparation method and application thereof

A technology of porous ceramics and pore walls, applied in the field of porous ceramics, can solve problems such as potential safety hazards and restrictions on the acceptance of the automobile market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] The present invention also provides a preparation method of the catalytic microreactor, comprising the following steps: after impregnating the silicon carbide porous substrate in the reverse microemulsion, drying, pre-oxidation treatment, cracking treatment, calcination and processing , to obtain the porous silicon carbide ceramic material; the inverse microemulsion includes an oil phase that is dissolved with a silicon source that can generate reducing gas and a carbon source that can adjust the oil phase viscosity and surface tension, and is dissolved with nickel ion water phase and emulsifier. The use of the carbon source can improve the film-forming performance of the inverse microemulsion by adjusting the viscosity and surface tension of the oil phase. The preparation method of the catalytic microreactor adopts a silicon source capable of generating a reducing atmosphere as the precursor of the silicon carbide film embedded with the nano-nickel particles. After th...

Embodiment 1

[0100] The present embodiment adopts a density of 1.95g / cm 3 , the open porosity is 38%, and the recrystallized porous silicon carbide with a pore diameter of about 50 microns is used as the matrix.

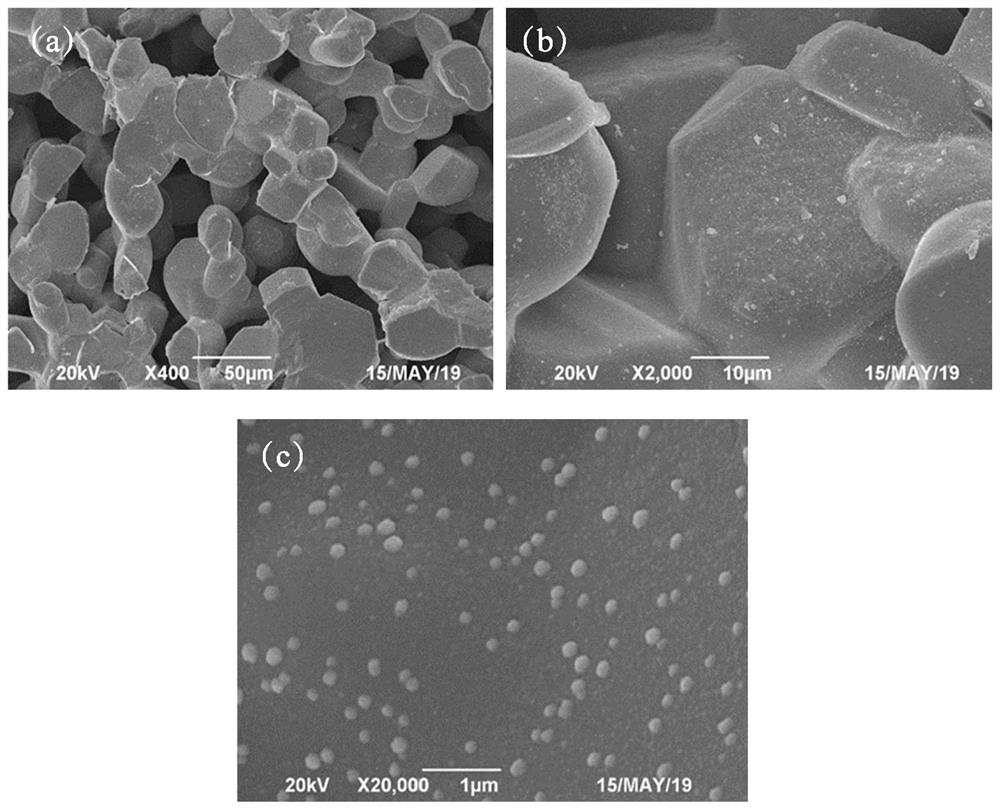

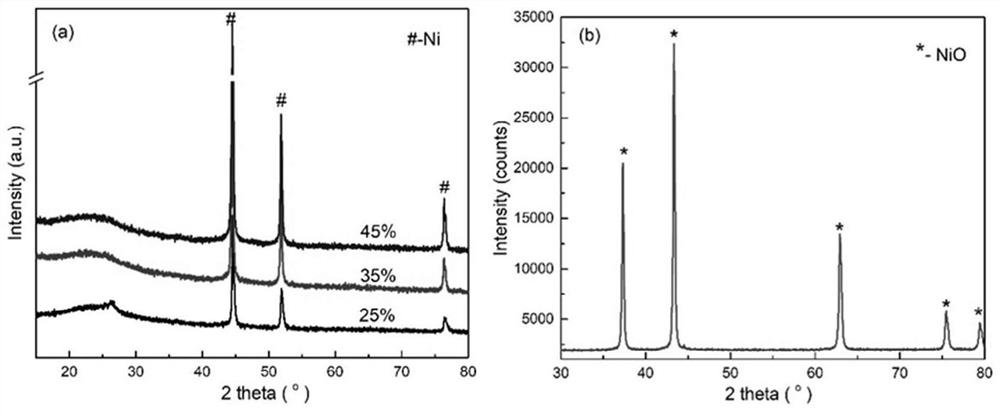

[0101] Mix 15g of xylene, 1g of epoxy resin, 1.6g of polycarbosilane, 0.5g of CTAB, 0.2g of span80, 2g of nickel nitrate, and 1g of water, stir, fully dissolve and emulsify as an inverse microemulsion, and make porous silicon carbide The substrate was immersed for 30 minutes, then taken out, dried at 30°C for 8 hours, pre-oxidized at 250°C for 120 minutes, and cracked at 600°C under an argon atmosphere to obtain the porous ceramic. The heating regime of the cracking treatment is to raise the temperature to 600° C. at a rate of 1° C. / min, and then keep the heat for 30 minutes. That is, a porous ceramic including an amorphous silicon carbide film with a thickness of 2 micrometers embedded with nickel particles of about 100 nanometers was obtained. figure 1 It is a micrograph of t...

Embodiment 2

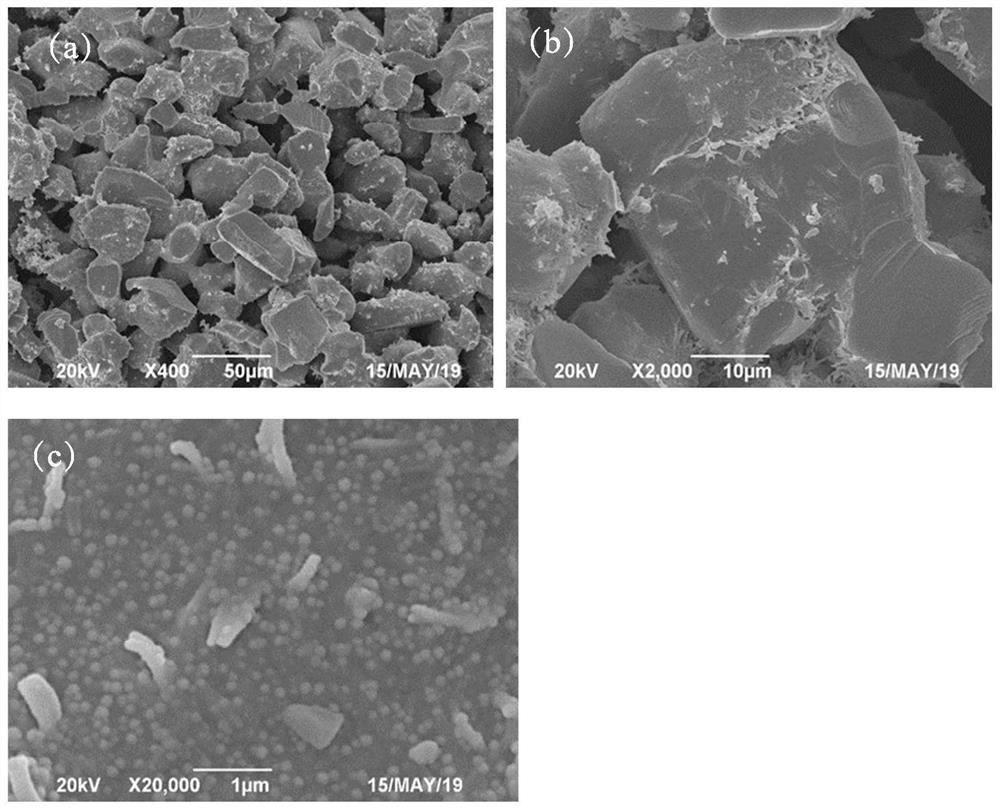

[0107] The present embodiment adopts a density of 1.85g / cm 3 The recrystallized porous silicon carbide with an open porosity of 41% and a pore diameter of about 100 microns is used as the matrix.

[0108] Mix 15g of xylene, 1g of epoxy resin, 1.6g of polycarbosilane, 0.8g of CTAB, 0.4g of DTAC, 3.5g of nickel nitrate, and 1g of water, stir, fully dissolve and emulsify as an inverse microemulsion, and carbonize the porous After the silicon was immersed for 50 minutes, it was taken out, dried at 50°C for 8 hours, pre-oxidized at 250°C for 120 minutes, and cracked at 800°C under an argon atmosphere to obtain the nickel particles embedded with about 120 nanometers and a thickness of 15 Micron porous ceramics with amorphous silicon carbide films.

[0109] The porous ceramic is used as a micro-reactor of the micro-reaction system after size processing, and the steam reforming of ethanol is carried out to produce hydrogen. The reaction temperature is 550 ° C, and the ethanol convers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com