Treatment method of arsenic-containing flue gas

A flue gas treatment and flue gas treatment system technology, applied in the field of comprehensive utilization of resources, can solve the problems of difficult recycling of dearsenic lye, high cost, poor dearsenic effect, etc. The effect of low water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

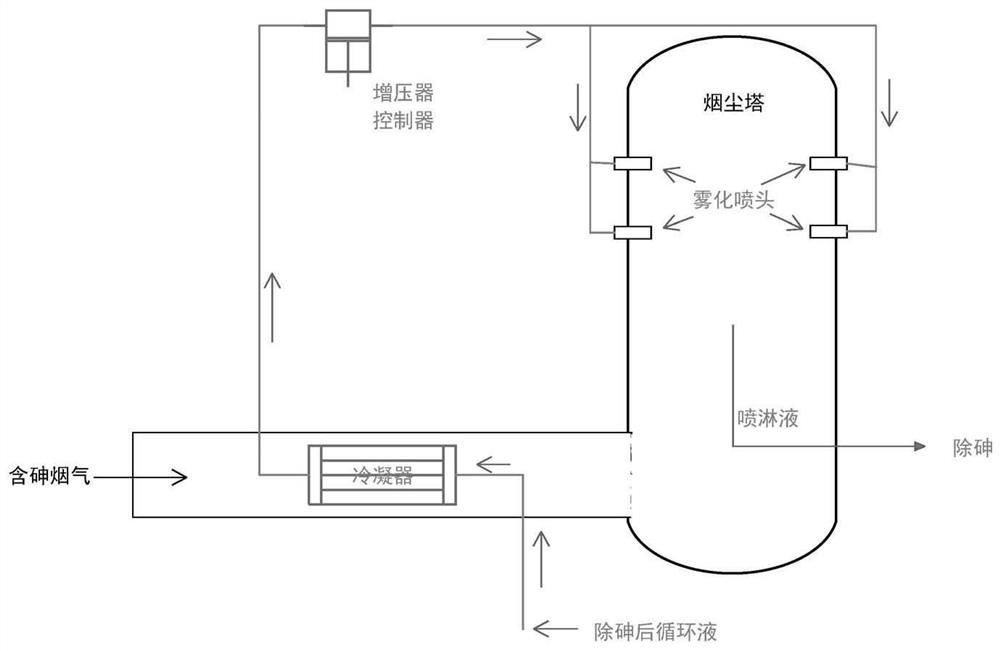

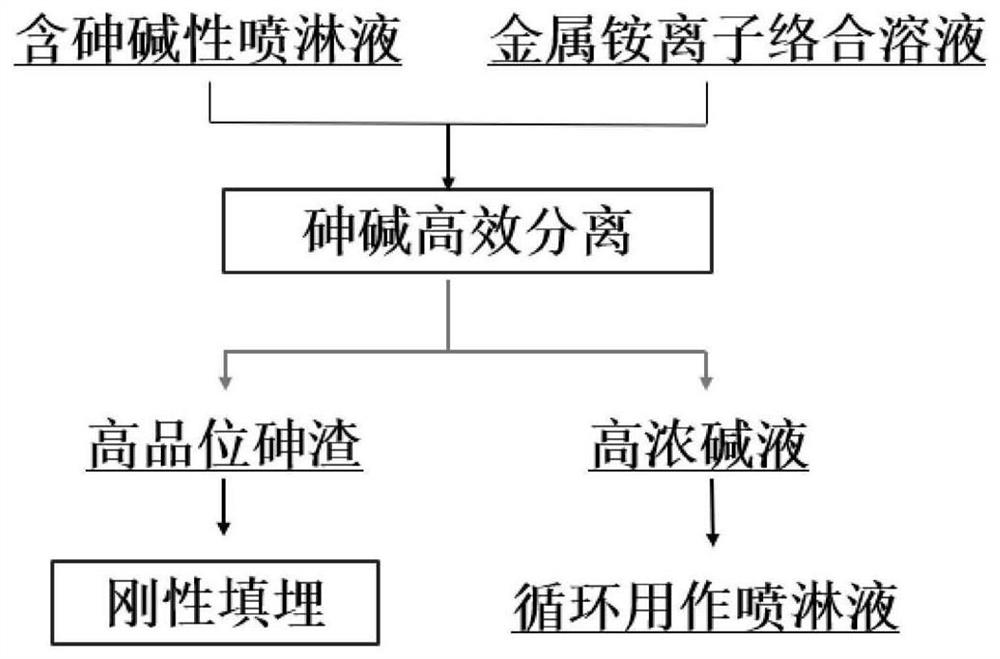

[0028] Using the above method to treat arsenic-containing flue gas produced by a rare and precious metal smelter, the flue gas volume is 55000Nm 3 / h, the dust content of the flue gas is about 0.02g / Nm 3 , where As 2 o 3 The content is about 2.17%. Previously, the traditional spraying method was used, and the arsenic content in the final exhausted flue gas was about 5.8mg / m 3 , far below the smoke emission standards. According to the flue gas treatment method provided in this article, 10 micro-mist nozzles (including accident nozzles) are designed on the upper part of the flue gas tower with a diameter of 5.2m. After pressurization, the pressure at the nozzle of each nozzle reaches about 130 Bar, and the water volume is 0.5m 3 About / h, the initial concentration of sodium carbonate in the spray liquid is 100g / L, and after the spray liquid and flue gas interact, the confluence flows to the arsenic-alkali separation system. According to the arsenic content in the arsenic-co...

Embodiment 2

[0031] This example mainly compares the effect of the addition of hydrogen peroxide on the process index. Using the above method to treat arsenic-containing flue gas produced by a rare and precious metal smelter, the flue gas volume is 55000Nm 3 / h, the dust content of the flue gas is about 0.02g / Nm 3 , where As 2 o 3 The content is about 2.17%. Previously, the traditional spraying method was used, and the arsenic content in the final exhausted flue gas was about 5.8mg / m 3, far below the smoke emission standards. According to the flue gas treatment method provided in this article, 10 micro-mist nozzles (including accident nozzles) are designed on the upper part of the flue gas tower with a diameter of 5.2m. After pressurization, the pressure at the nozzle of each nozzle reaches about 130 Bar, and the water volume is 0.5m 3 About / h, the initial concentration of sodium carbonate in the spray liquid is 100g / L, and after the spray liquid and flue gas interact, the confluence...

Embodiment 3

[0034] This example mainly compares the influence of the number of micro-mist nozzles on the process index. Using the above method to treat arsenic-containing flue gas produced by a rare and precious metal smelter, the flue gas volume is 55000Nm 3 / h, the dust content of the flue gas is about 0.02g / Nm 3 , where As 2 o 3 The content is about 2.17%. Previously, the traditional spraying method was used, and the arsenic content in the final exhausted flue gas was about 5.8mg / m 3 , far below the smoke emission standards. According to the flue gas treatment method provided in this article, 10 micro-mist nozzles (including accident nozzles) are designed on the upper part of the flue gas tower with a diameter of 5.2m. In the comparative example, only 6 micro-mist nozzles are designed to work. The pressure at the nozzle of each nozzle reaches about 130Bar, and the water volume is 0.5m 3 About / h, the initial concentration of sodium carbonate in the spray liquid is 100g / L, and aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com