Waste acid purifying method

A pickling and dilute acid technology, applied in chemical instruments and methods, metallurgical wastewater treatment, photography technology, etc., to achieve the effect of saving water resources, stable water output, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

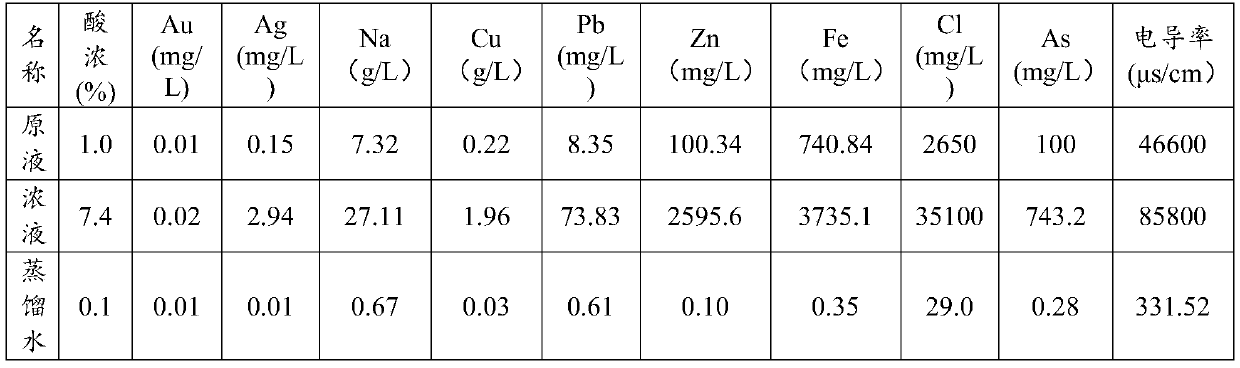

Embodiment 1

[0015] A method for recycling waste acid, comprising the following steps:

[0016] 1) Waste acid output: The roasting acid production process is to use the secondary raffinate produced in step 5) to adjust the slurry of polymetallic gold concentrates containing arsenic, carbon, copper, and zinc, and control the concentration of the slurry to 65%. After 600°C Roasting, the flue gas containing arsenic trioxide, sulfur dioxide, and mine dust produced during the roasting process is produced by gravity dust removal, electric dust removal, wet quenching to remove arsenic, pickling purification, electric fog removal, and secondary conversion and secondary absorption processes. Sulfuric acid products, the concentration of sulfuric acid produced in the pickling and purification process is 1%, and the arsenic-containing dilute acid containing 1000mg / l arsenic; It is an acid leaching solution, and the arsenic content in the acid leaching solution reaches 1000mg / l. The arsenic-containing ...

Embodiment 2

[0025] A method for recycling waste acid, comprising the following steps:

[0026] 1) Output of waste acid: The roasting acid production process is to use the secondary raffinate produced in step 5) to adjust the slurry of polymetallic gold concentrates containing arsenic, carbon, copper, and zinc, and control the concentration of the slurry to 68%. After 700°C Roasting, the flue gas containing arsenic trioxide, sulfur dioxide, and mine dust produced during the roasting process is produced by gravity dust removal, electric dust removal, wet quenching to remove arsenic, pickling purification, electric fog removal, and secondary conversion and secondary absorption processes. Sulfuric acid products, sulfuric acid produced in the pickling purification process with a sulfuric acid concentration of 5% and arsenic-containing dilute acid containing 2000 mg / l of arsenic; the acidic liquid produced by roasting the calcined sand through the acid leaching section and the filtering and wash...

Embodiment 3

[0035] A method for recycling waste acid, comprising the following steps:

[0036] 1) Waste acid output: The roasting acid production process is to use the secondary raffinate produced in step 5) to adjust the slurry of polymetallic gold concentrates containing arsenic, carbon, copper, and zinc, and control the concentration of the slurry to 70%. After 800 ° C Roasting, the flue gas containing arsenic trioxide, sulfur dioxide, and mine dust produced during the roasting process is produced by gravity dust removal, electric dust removal, wet quenching to remove arsenic, pickling purification, electric fog removal, and secondary conversion and secondary absorption processes. Sulfuric acid products, the output of sulfuric acid concentration in the pickling purification process is 10%, and the arsenic-containing dilute acid containing 3000mg / l of arsenic; the acidic liquid produced by the calcined sand after roasting through the acid leaching section and the filtering and washing se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com