Chlorine dioxide purification gel powder and preparation method thereof

A chlorine dioxide, gel powder technology, applied in the fields of botanical equipment and methods, chemicals for biological control, animal repellants, etc., can solve the problem of low chlorine dioxide content, absorption capacity limitation, explosive release, etc. problem, to achieve the effect of stable release of chlorine dioxide, simple preparation method and uniform mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method for chlorine dioxide purification gel powder, comprising the following steps:

[0038] First, prepare starch polymer resin activator;

[0039] Second, mix the starch polymer resin activator, chlorite, and stabilizer in a mixer, and adjust the agent and catalyst in turn, and fully stir and mix.

[0040] The step of preparing starch polymer resin activation in the first step comprises:

[0041] S1, select the starch polymer resin matrix;

[0042] S2, acid modification, adding mixed acid to the starch polymer resin matrix, and the concentration of the mixed acid is 50-300g / L, and the mass ratio of the starch polymer resin matrix to the mixed acid is 1:5-1:500, and fully Stir slowly until dissolved;

[0043]S3, add 0.1-1% of N-methyldiethanolamine, and 1-10% of the label 50-200 polyethylene glycol, and mix uniformly; the mass percentage is based on the mass after mixing in this step;

[0044] S4, drying the mixed solution of S3 in a microwave with a...

Embodiment 1

[0053] Use 65% HPMC (hydroxypropyl methyl cellulose) and 35% CMC (carboxymethyl cellulose) as the starch polymer resin matrix, add concentration wherein to be 250g / L mixed acid solution, and citric acid is 150g in the mixed acid / L, sulfamic acid is 100g / L, and the mass ratio of matrix quality and acid is=1: 30. After mixing evenly and dissolving, add 0.1% N-methyldiethanolamine and 1% PEG 80 in total mass after mixing. Mix well, place in microwave drying equipment, and dry with 800W. Then it was pulverized to 200 mesh to obtain a starch polymer resin matrix. Then according to the mass ratio of sodium chlorite and starch polymer resin matrix of 1:5, add sodium chlorite and mix well. Then according to the mass fraction, add 10% magnesium sulfate, 25% anhydrous sodium sulfate, 1% sodium dihydrogen phosphate, 0.5% potassium phosphate, 4% sodium alginate, 1% guar gum powder, 0.5% activated alumina.

[0054] When in use, add clear water to the gel according to powder:water=1:5. ...

Embodiment 2

[0057] 60% HPMC and 40% CMC were used as a matrix, and a mixed acid solution with a concentration of 200 g / L was added thereto. In the mixed acid, citric acid is 120g / L, sulfamic acid is 80g / L, the mass ratio of substrate mass and acid is=1:50, after mixing and dissolving, add 0.2% N-methyldiethanolamine, and after mixing PEG80 with a total mass of 1.5%, mixed evenly, placed in microwave drying equipment, and dried with 800W. Then it was pulverized to 200 mesh to obtain a starch polymer resin matrix. Then according to the mass ratio of sodium chlorite and starch polymer resin matrix of 1:5, add sodium chlorite and mix well. Then according to the mass fraction, add 10% magnesium sulfate, 20% anhydrous sodium sulfate, 1% sodium dihydrogen phosphate, 0.5% potassium phosphate, 5% sodium alginate, 0.1% guar gum powder, 0.5% activated alumina.

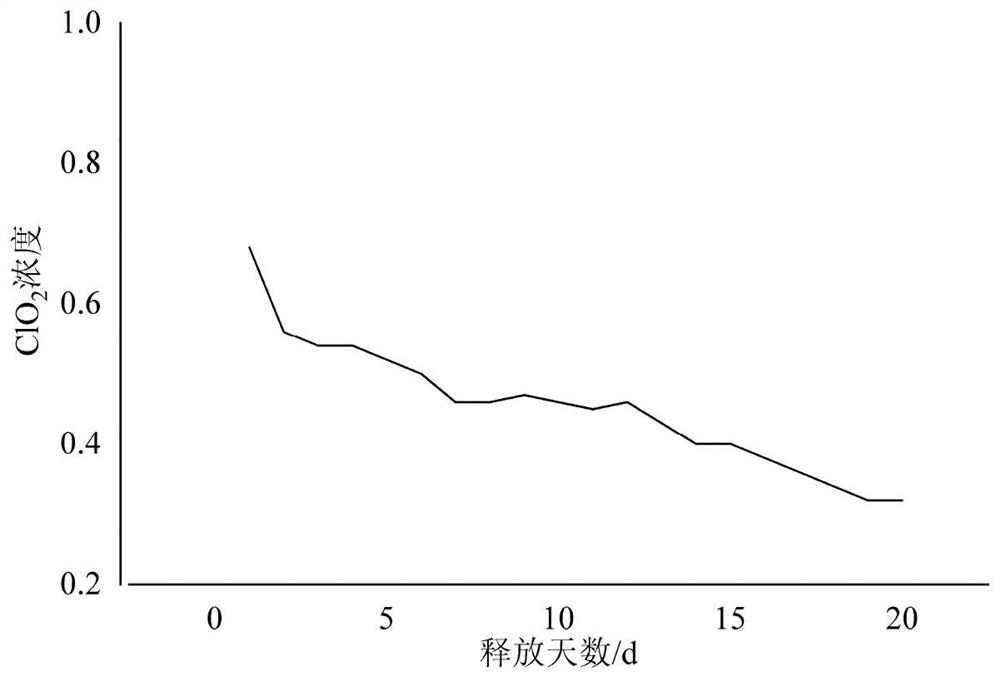

[0058] When in use, add clear water to the gel according to powder:water=1:5. The gel can be formed within 30 seconds and can be release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com