High-manganese austenitic steel and preparation method thereof

A technology of austenitic steel and high manganese is applied in the field of high manganese austenitic steel and its preparation, which can solve the problems of unsatisfactory, low yield strength and tensile strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

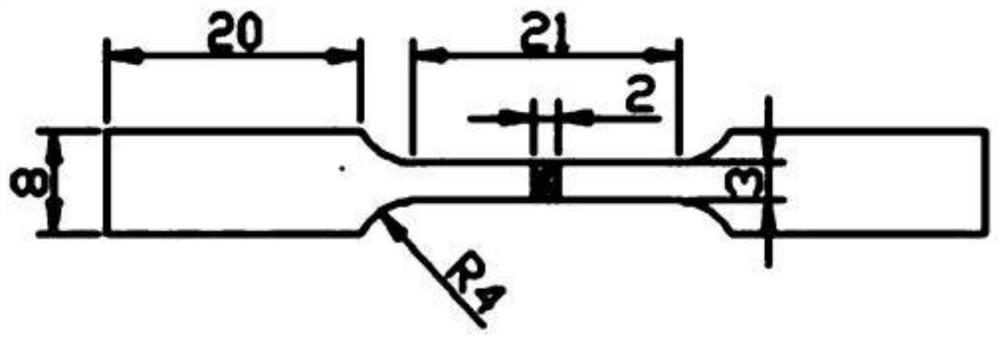

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing high manganese austenitic steel described in the above technical solution, comprising the following steps:

[0032] (1) smelting after mixing alloy raw materials to obtain alloy ingots;

[0033] (2) hot rolling the alloy ingot obtained in the step (1) to obtain an alloy plate;

[0034] (3) The alloy plate obtained in the step (2) is sequentially subjected to solution treatment and aging treatment to obtain high manganese austenitic steel.

[0035] The invention mixes and smelts alloy raw materials to obtain alloy ingots.

[0036] In the present invention, there is no special limitation on the type of the alloy raw material, and the raw material known to those skilled in the art that can provide the above alloy elements can be used. In the present invention, the alloy raw material is preferably carbon, electrolytic manganese sheet, niobium wire, aluminum block and iron block, more preferably carbon, electrolyti...

Embodiment 1

[0061] In terms of mass percentage, the composition of high manganese austenitic steel is: Mn: 25%, Al: 10%, C: 1.4%, Nb: 0.05% and the balance is Fe.

[0062] The preparation method of high manganese austenitic steel is:

[0063] (1) Take 87.492g of industrial pure iron, 34.664g of electrolytic manganese, 13.865g of pure aluminum, and 0.069g of niobium wire and immerse them in an anhydrous ethanol beaker, put the beaker into an ultrasonic cleaner for cleaning, add 1.941g of carbon, and Put carbon, electrolytic manganese sheet, niobium wire, aluminum block, and industrial pure iron into the water-cooled copper crucible of the non-consumable vacuum arc melting furnace, and the vacuum degree in the furnace cavity must reach 8×10 - 3 Below Pa, fill it with high-purity argon as a protective gas and then smelt it. After each smelting, the ingot is turned over, and the ingot is smelted and turned over repeatedly to obtain an alloy ingot with a thickness of 14.7mm;

[0064] (2) Hea...

Embodiment 2

[0070] In terms of mass percentage, the composition of high manganese austenitic steel is: Mn: 26%, Al: 10%, C: 1.4%, Nb: 0.1% and the balance is Fe.

[0071] The preparation method of high manganese austenitic steel is:

[0072] (1) Take 88.046g of industrial pure iron, 36.628g of electrolytic manganese, 14.088g of pure aluminum, and 0.141g of niobium wire and immerse them in an anhydrous ethanol beaker. After cleaning the beaker in an ultrasonic cleaner, add 1.972g of carbon, and then Put carbon, electrolytic manganese sheet, niobium wire, aluminum block, and industrial pure iron into the water-cooled copper crucible of the non-consumable vacuum arc melting furnace, and the vacuum degree in the furnace cavity must reach 8×10 - 3 Below Pa, fill it with high-purity argon as a protective gas and then smelt it. After each smelting, the ingot is turned over, and the ingot is smelted and turned over repeatedly to obtain an alloy ingot with a thickness of 14.7mm;

[0073] (2) Hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com