Heat dissipation composition of semiconductor device and preparation method thereof

A technology of semiconductor and composition, applied in the field of heat dissipation composition and preparation thereof, can solve the problems of poor formability of epoxy resin composition and reduced adhesiveness of substrates and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

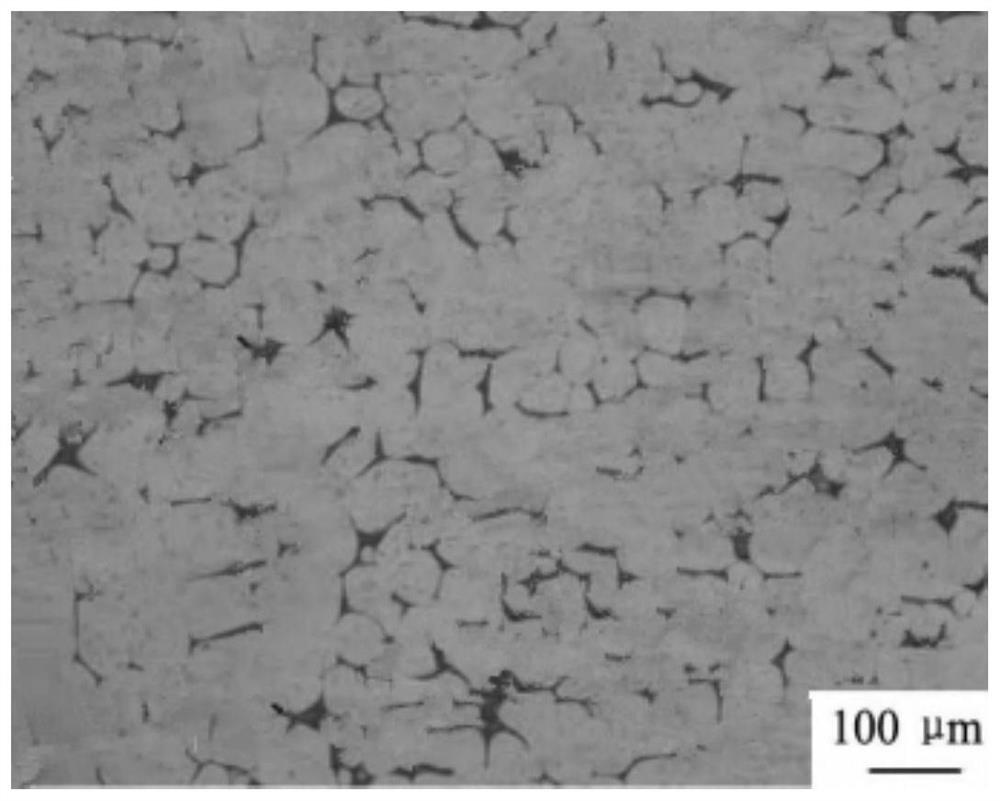

Image

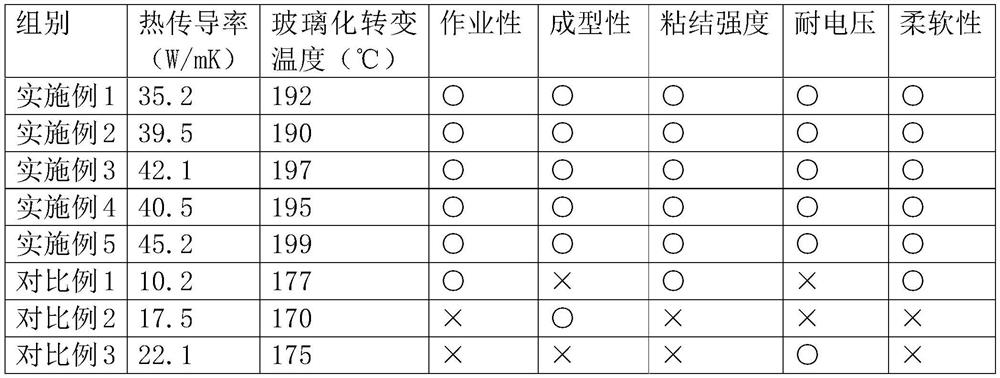

Examples

Embodiment 1

[0039] Composition of raw materials (parts by weight): 10 parts of thermally conductive metal paste, 50 parts of phenolic epoxy resin, 70 parts of furan resin, 1 part of potassium stearate, 1 part of polytetrafluoroethylene, 30 parts of ethylene glycol phenyl ether, 10 parts of phenol share.

[0040] The preparation method of thermally and electrically conductive metal paste is as follows:

[0041] S1. Casting ingots: casting 100 parts by weight of copper ingots, 10 parts by weight of silver ingots, 1 parts by weight of tin ingots and 5 parts by weight of zinc ingots is processed into cube ingredients of 25mm * 25mm * 25mm with metal mold casting;

[0042] S2. Rolling deformation: the processed billet is cold-rolled and deformed by a two-roll mill at room temperature. After the two-pass rolling is completed, the cumulative deformation is 12%;

[0043]S3. Remelting treatment: Put the cold-rolled and deformed sample into a power frequency induction heating furnace and heat it t...

Embodiment 2

[0050] Raw material composition (parts by weight): 30 parts of thermally conductive metal paste, 100 parts of glycidyl ether epoxy resin, 120 parts of thermosetting acrylic resin, 5 parts of hindered phenol, 3 parts of molybdenum disulfide, 100 parts of ethylene glycol phenyl ether , 20 parts of phenol.

[0051] The preparation method of thermally and electrically conductive metal paste is as follows:

[0052] S1. Casting ingots: casting 100 parts by weight of copper ingots, 25 parts by weight of silver ingots, 5 parts by weight of tin ingots and 15 parts by weight of zinc ingots is processed into a cube batch of 25mm * 25mm * 25mm with metal mold casting;

[0053] S2. Rolling deformation: the processed billet is cold-rolled and deformed by a two-roll rolling mill at room temperature. After the two-pass rolling is completed, the cumulative deformation is 17%;

[0054] S3. Remelting treatment: put the cold-rolled and deformed sample into a power frequency induction heating fur...

Embodiment 3

[0061] Composition of raw materials (parts by weight): 15 parts of thermally conductive metal paste, 70 parts of diphenol-based propane type epoxy resin, 90 parts of polybutadiene resin, 2 parts of aluminum stearate, 1 part of silicone oil, 50 parts of ethylene glycol phenyl ether Parts, 12 parts of phenol.

[0062] The preparation method of thermally and electrically conductive metal paste is as follows:

[0063] S1. Casting ingots: 100 parts by weight of copper ingots, 12 parts by weight of silver ingots, 2 parts by weight of tin ingots and 7 parts by weight of zinc ingots are processed into cube ingredients of 25mm * 25mm * 25mm by metal mold casting;

[0064] S2. Rolling deformation: the processed billet is cold-rolled and deformed by a two-roll rolling mill at room temperature. After the two-pass rolling is completed, the cumulative deformation is 13%;

[0065] S3. Remelting treatment: put the cold-rolled and deformed sample into a power frequency induction heating furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com