Leachate treatment system and method suitable for waste incineration power plant

A waste incineration and treatment system technology, applied in the direction of contaminated groundwater/leachate treatment, sedimentation treatment, multi-stage water treatment, etc., can solve the problems of rising treatment costs, difficult replacement of filter materials, and easy hardening of filters, etc., to achieve Reduce the amount of chemicals used, reduce treatment costs, and have no secondary pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

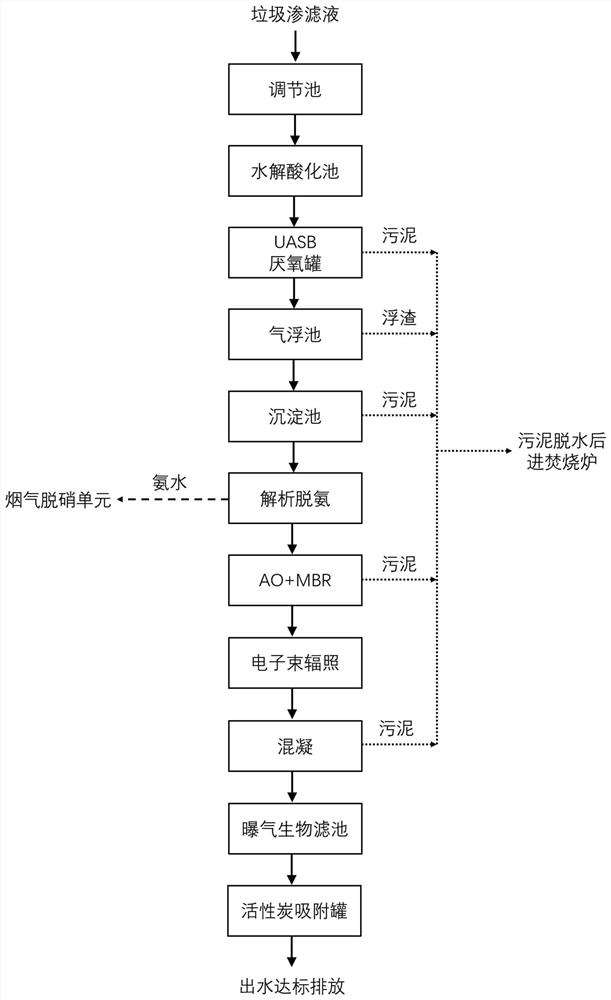

Method used

Image

Examples

Embodiment 1

[0050] The basic water quality of the leachate of a waste incineration plant in Hebei is as follows: pH is 6.6-6.8; COD concentration is 55000-75000mg / L; ammonia nitrogen concentration is 660-750mg / L; total nitrogen concentration is about 1000-1280mg / L. Utilize leachate treatment system of the present invention to carry out leachate treatment, concrete method step is as follows:

[0051] 1. The leachate enters the regulating tank to adjust the water volume and quality;

[0052] 2. The effluent from the adjustment tank enters the hydrolysis and acidification tank. After hydrolysis and acidification, the pH of the water drops to 5.3, and the pH value is adjusted to 6.9 to 7.2 with sodium carbonate to meet the conditions for methanation in the UASB anaerobic reaction tank;

[0053] 3. The effluent from the hydrolytic acidification tank enters the UASB anaerobic reaction tank to remove most of the organic matter in the water. The effluent pH is 7.8-8.0, the COD concentration is 9...

Embodiment 2

[0064] The basic water quality of the leachate of a waste incineration plant in Anhui is as follows: pH is 6.1-6.5; COD concentration is 50000-65000mg / L; ammonia nitrogen concentration is 480-630mg / L; total nitrogen concentration is about 910-1200mg / L.

[0065] Adopt the method for embodiment 1 to process this leachate, difference is:

[0066] Adjust the pH of the effluent from the pool to 5.4, and use sodium carbonate to adjust the pH to 6.8-7.0;

[0067] The air-water ratio of the air flotation tank is controlled at 16:1, and the ascending flow rate is controlled at 3m / h;

[0068] After the effluent from the sedimentation tank undergoes heat exchange with the effluent from the analytical deamination tower, the temperature is raised to 42°C and enters the analytical deamination tower;

[0069] Use the low-temperature and low-pressure steam (temperature 100-110°C, pressure 0.3-0.4MPa) produced by the waste incineration plant to provide heat, and deamination is carried out und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com