Phase-change material lubricated airplane anti-icing surface implementation method

A technology of phase change materials and realization methods, applied in chemical instruments and methods, devices for coating liquid on the surface, coatings, etc., can solve the problems of surface anti-icing performance decline, lubricant consumption, failure, etc., and achieve extended use The effect of lifespan and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment includes the following steps:

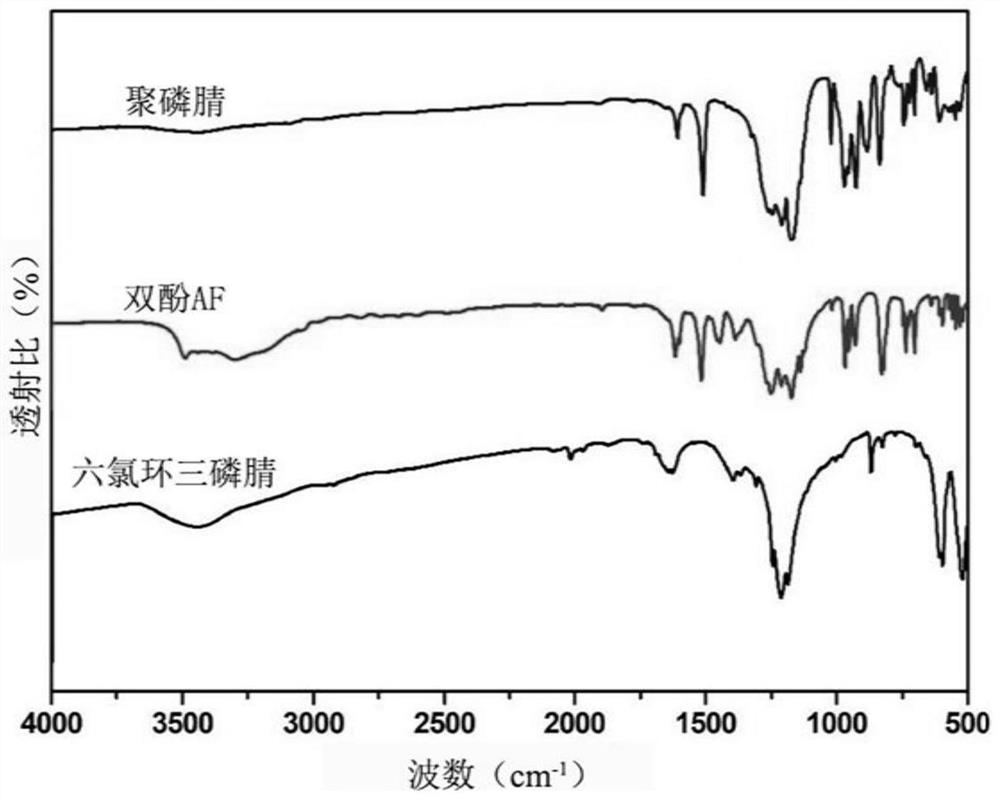

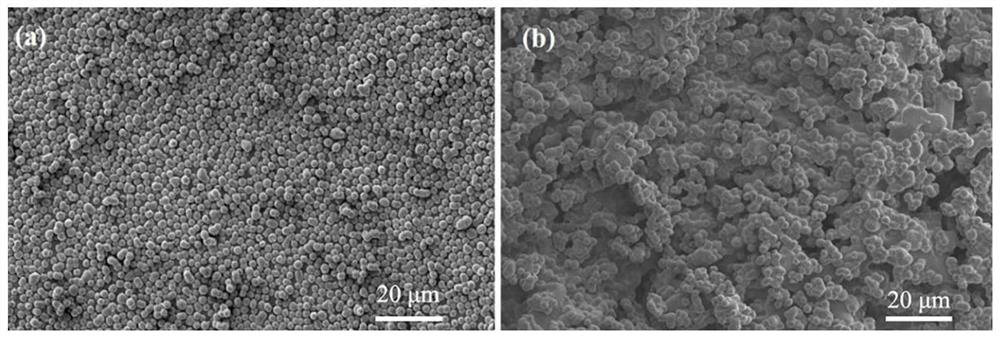

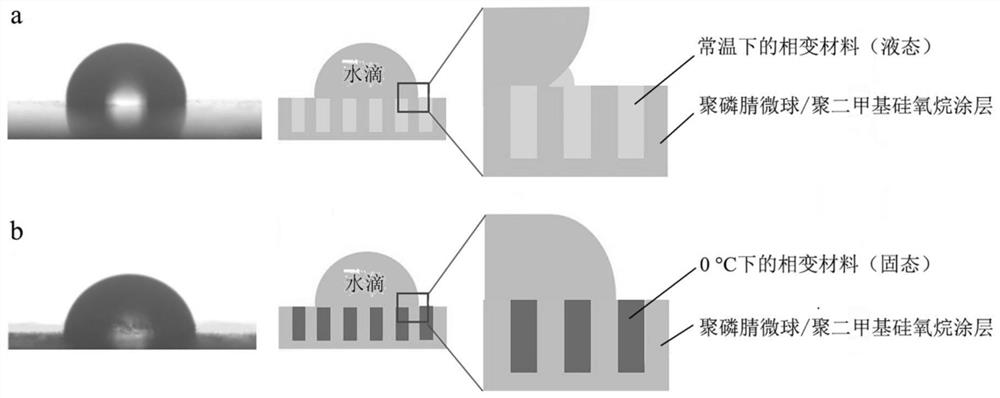

[0030] ①Add 80.00mL of acetonitrile, 0.40g of hexachlorocyclotriphosphazene and 1.16g of bisphenol AF into the round bottom flask in turn, and stir evenly at room temperature. After hexachlorocyclotriphosphazene and bisphenol AF were completely dissolved, 4.00 mL of triethylamine was added to the above-mentioned round bottom flask, and stirring was continued at room temperature. After the above mixture was fully mixed, the above round bottom flask was placed in a water bath at 50° C. and subjected to ultrasonic treatment at a power of 100 W for 5 hours. The obtained product was first washed with absolute ethanol, and then centrifuged, and the washing and centrifuging process was repeated three times; then the obtained solid was washed with deionized water, and then centrifuged, and the washing and centrifuging process was repeated three times. The final mixture was vacuum-dried at 60° C. for 10 hours, and then the complet...

Embodiment 2

[0037] This embodiment includes the following steps:

[0038] ①Add 80.00mL of acetonitrile, 0.40g of hexachlorocyclotriphosphazene and 1.16g of bisphenol AF into the round bottom flask in turn, and stir evenly at room temperature. After hexachlorocyclotriphosphazene and bisphenol AF were completely dissolved, 4.00 mL of triethylamine was added to the above-mentioned round bottom flask, and stirring was continued at room temperature. After the above mixture was fully mixed, the above round bottom flask was placed in a water bath at 50° C. and subjected to ultrasonic treatment at a power of 100 W for 5 hours. The obtained product was first washed with absolute ethanol, and then centrifuged, and the washing and centrifuging process was repeated three times; then the obtained solid was washed with deionized water, and then centrifuged, and the washing and centrifuging process was repeated three times. The final mixture was vacuum-dried at 60° C. for 10 hours, and then the complet...

Embodiment 3

[0042] This embodiment includes the following steps:

[0043] ①Add 80.00mL of acetonitrile, 0.40g of hexachlorocyclotriphosphazene and 1.16g of bisphenol AF into the round bottom flask in turn, and stir evenly at room temperature. After hexachlorocyclotriphosphazene and bisphenol AF were completely dissolved, 4.00 mL of triethylamine was added to the above-mentioned round bottom flask, and stirring was continued at room temperature. After the above mixture was fully mixed, the above round bottom flask was placed in a water bath at 50° C. and subjected to ultrasonic treatment at a power of 100 W for 5 hours. The obtained product was first washed with absolute ethanol, and then centrifuged, and the washing and centrifuging process was repeated three times; then the obtained solid was washed with deionized water, and then centrifuged, and the washing and centrifuging process was repeated three times. The final mixture was vacuum-dried at 60° C. for 10 hours, and then the complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com