Preparation method of cigar-flavored cigarette paper

A technology for cigarette paper and cigars, applied in the directions of microorganism-based methods, biochemical equipment and methods, paper, etc., can solve the problems of shortage of high-quality cigar tobacco raw materials, uneven release of flavors and fragrances, and increased release of harmful components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

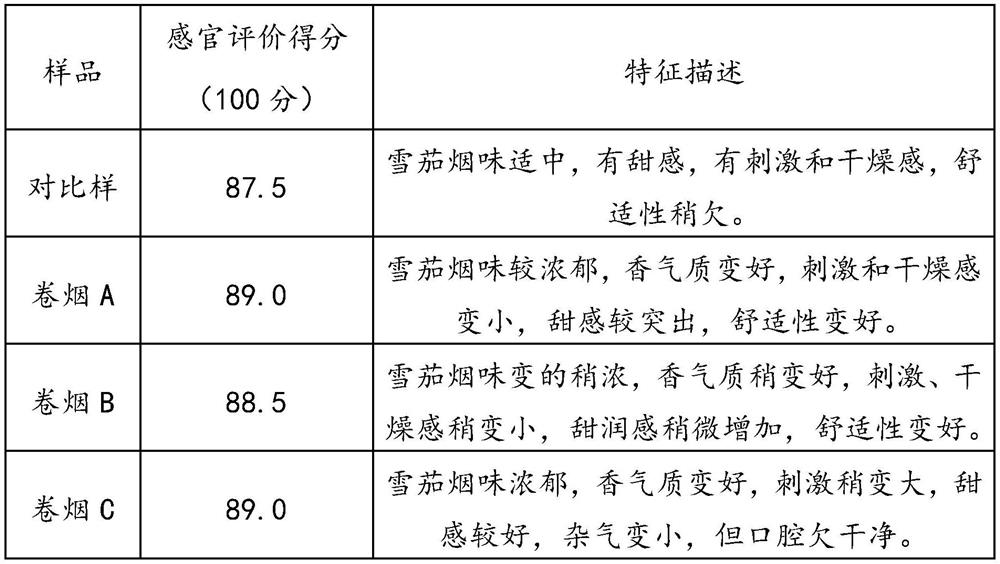

Examples

Embodiment 1

[0026] Weigh 5.0kg of cigar powder, add 50.0kg of water, soak for 2 hours, heat to boiling under mechanical stirring, keep a slightly boiling state for 2 hours, cool down to room temperature, collect the filtrate by filtration under reduced pressure, and remove about 1 / 4 of the filtrate by distillation under reduced pressure. After the volume of water, the cigar extract is obtained.

[0027] Adjust the pH value of the above cigar extract to 5 with dilute acetic acid with a volume percentage of 10%, then divide it into a conical flask with a stopper, seal the mouth with a sealing film, and sterilize it in a sterilizing pot at 120°C for 20min n .

[0028] The black tea strain was inserted into the above-mentioned sterilization solution with an inoculation amount of 6% by weight of the cigar extract in a conical flask with a stopper, and after being sufficiently shaken, it was cultured at a constant temperature of 30° C. for 2 weeks. After 2 weeks, the resulting brown bacterial ...

Embodiment 2

[0033] Weigh 5.0kg of cigar powder, add 50.0kg of water, soak for 3 hours, heat to boiling under mechanical stirring, keep a slightly boiling state for 3 hours, cool to room temperature, collect the filtrate by filtration under reduced pressure, and remove about 1 / 5 of the filtrate by distillation under reduced pressure. After the volume of water, the cigar extract is obtained.

[0034] Adjust the pH of the above cigar extract to 6 with dilute acetic acid with a volume percentage of 10%, then divide it into a conical flask with a stopper, seal it with a sealing film, and sterilize it in a sterilizing pot at 120°C for 30min n .

[0035] The strain of Acetobacter xylinum was inserted into the above-mentioned sterilizing solution with an inoculum amount of 4% by weight of the cigar extract in the conical flask with a stopper, and after sufficient shaking, it was cultured at a constant temperature of 30° C. for 2 weeks. After 2 weeks, the resulting brown bacterial cellulose film ...

Embodiment 3

[0040] Weigh 5.0kg of cigar powder, add 48.0kg of water, soak for 2 hours, heat to boiling under mechanical stirring, keep a slightly boiling state for 2 hours, cool to room temperature, collect the filtrate by filtration under reduced pressure, and remove about 1 / 3 of the filtrate by distillation under reduced pressure. After the volume of water, the cigar extract is obtained.

[0041] Adjust the pH of the above cigar extract to 5.6 with dilute acetic acid with a volume percentage of 10%, and then divide it into a conical flask with a stopper, seal the mouth with a sealing film, and sterilize it in a sterilizer at 120°C for 20min n .

[0042] The Acetobacter xylinum strain was inserted into the above-mentioned sterilization solution at an inoculum amount of 3% of the weight of the cigar extract in the conical flask with a stopper, and after being sufficiently shaken, it was cultured at a constant temperature of 30° C. for 2 weeks. After 2 weeks, the resulting brown bacterial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com