Toughening agent composition and preparation method thereof

A composition and toughening agent technology, applied in the field of toughening agent composition and its preparation, can solve the problems of reducing the degree of crosslinking, more additives, reducing the degree of crosslinking of POE, etc., to achieve reduced degree of crosslinking and good flow Sex, the effect of increasing the grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

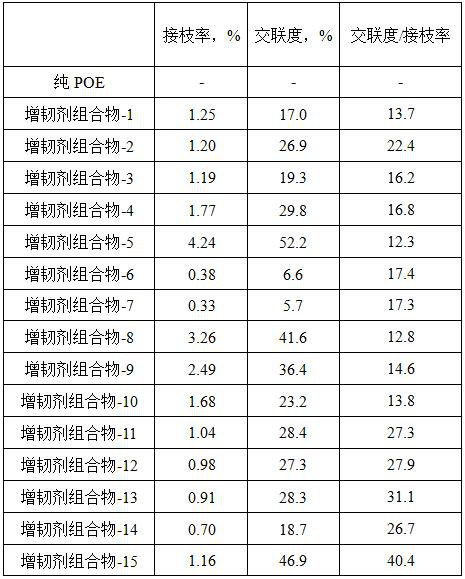

Examples

Embodiment 1

[0025] 64.0% POE resin (density 0.870 g / cm -3 , melt index is 5g / 10min), 30.0% low-density polyethylene, 3.0% GMA, 1.5% styrene, 0.3% 2,5-di-tert-butylperoxy-2,5-dimethylhexane (low melting point at 8°C) and 1.2% talc powder (particle size D90 = 5 microns) are uniformly mixed in a high-speed mixer, and then fed into a twin-screw extruder through a feeding hopper for reactive extrusion. The used twin-screw extruder Length-to-diameter ratio L / D=36, the extrusion temperatures of the first to ninth stages are: 60°C, 100°C, 190°C, 190°C, 190°C, 190°C, 200°C, 210°C, 170°C, screw speed Toughening agent composition-1 can be obtained after the material is melted and plasticized, extruded, dried and pelletized at 250 rpm.

Embodiment 2

[0027] 64.0% POE resin (density 0.870 g / cm -3 , melt index is 5g / 10min), 30.0% low density polyethylene, 3.0% GMA, 1.5% styrene, 0.3% dicumyl peroxide (DCP, solid initiator, melting point is 42°C) and 1.2% talc (Particle size is D90=5 microns) After mixing evenly in the high-speed mixer, it is fed into the twin-screw extruder through the feeding hopper for reactive extrusion. The length-to-diameter ratio of the twin-screw extruder used is L / D=36, The extrusion temperatures of the first to ninth stages are: 60°C, 100°C, 190°C, 190°C, 190°C, 190°C, 200°C, 210°C, 170°C, the screw speed is 250 rpm, and the material is melted Toughener Composition-2 can be obtained after plasticizing, extruding, drying and pelletizing.

Embodiment 3

[0029] 64.0% POE resin (density 0.870 g / cm -3 , melt index is 5g / 10min), 30.0% low-density polyethylene, 3.0% GMA, 1.5% styrene, 0.3% 2,5-di-tert-butylperoxy-2,5-dimethylhexane (low melting point at 8°C) and 1.2% talc powder (particle size D90=20 microns) are uniformly mixed in a high-speed mixer, and then fed into a twin-screw extruder through a feeding hopper for reactive extrusion. The used twin-screw extruder Length-to-diameter ratio L / D=36, the extrusion temperatures of the first to ninth stages are: 60°C, 100°C, 190°C, 190°C, 190°C, 190°C, 200°C, 210°C, 170°C, screw speed Toughening agent composition-3 can be obtained after the material is melted and plasticized, extruded, dried and pelletized at 250 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com