Fine-grain pink ZTA ceramic and preparation method thereof

A fine-grain, pink technology, applied in the field of fine-grain pink ZTA ceramics and its preparation, can solve the problems of ceramic grain growth, uneven distribution, and reduction of material strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

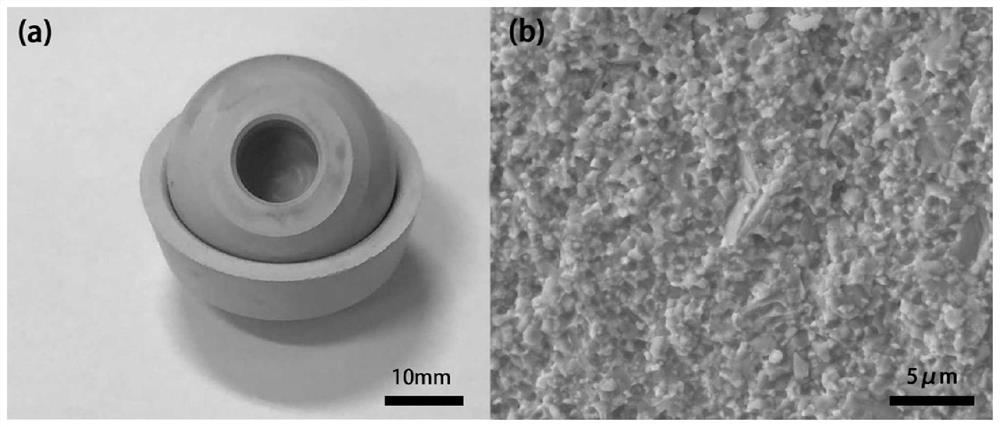

Image

Examples

Embodiment 1

[0048] The raw material powder used in this embodiment includes 68 parts by weight of alumina, 30 parts of 2 moles of yttria-stabilized zirconia (2YSZ), 1.8 parts of strontium carbonate and 0.3 parts of dichromium trioxide. Among them, the average particle size of alumina powder is 0.30 μm, the average particle size of 2YSZ is 0.08 μm, and the average particle size of chromium trioxide powder is 0.70 μm. The preparation method steps of this embodiment are as follows:

[0049] (1) Preparation of ZTA slurry. Add an appropriate amount of ammonia water to adjust the pH value of the water between 9.5; add ammonium polyacrylate accounting for 0.6% of the total powder weight; then add the raw material powder to the ball milling medium so that the volume of the raw material powder accounts for 35% of the total volume of the water and the powder, and then Add polyvinyl alcohol accounting for 3% of the weight of the raw material powder; after ball milling for 60 hours, a low-viscosity ...

Embodiment 2

[0056] The raw material powder that present embodiment adopts comprises the aluminum oxide that parts by weight are 74, 24 parts of 3 moles of yttrium oxide stabilized zirconia (3YSZ), the calcium carbonate of 0.7 part, the magnesium carbonate of 0.5 part and the dichromium trioxide of 0.5 part . Among them, the average particle size of alumina powder is 0.20 μm, the average particle size of 3YSZ is 0.08 μm, and the average grain size of chromium trioxide powder is 0.50 μm. The preparation method steps of this embodiment are as follows:

[0057] (1) Preparation of ZTA slurry: add an appropriate amount of ammonia water to adjust the pH value of the water between 9.5; add diammonium citrate accounting for 0.4% of the total powder weight; then add the raw material powder to the ball milling medium, so that the volume of the raw material powder occupies 30% of the total volume of water and powder, and then adding polyvinyl alcohol accounting for 2% of the weight of the raw materi...

Embodiment 3

[0064] The raw material powder used in this embodiment includes 80 parts by weight of alumina, 18 parts of 3 mole yttria-stabilized zirconia (3YSZ), 1.5 parts of strontium carbonate and 0.5 parts of dichromium trioxide. Among them, the average particle size of alumina powder is 0.25 μm, the average particle size of 3YSZ is 0.15 μm, and the average grain size of chromium trioxide powder is 0.20 μm. The preparation method steps of this embodiment are as follows:

[0065] (1) Preparation of ZTA slurry: add an appropriate amount of ammonia water to adjust the pH value of the water to 10.5; add ammonium polyacrylate accounting for 0.8% of the total powder weight; then add the raw material powder to the ball milling medium so that the volume of the raw material powder accounts for the volume of the water and the powder 35% of the total volume, and then add polyvinyl alcohol accounting for 2% of the weight of the raw material powder; after ball milling for 60 hours, a low-viscosity Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com