Antioxidant copper material and preparation method thereof

A technology of copper oxide and copper oxide powder, applied in the direction of conductive materials, conductive materials, metal material coating technology, etc., can solve the problems of complex process, poor anti-oxidation effect, high preparation cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

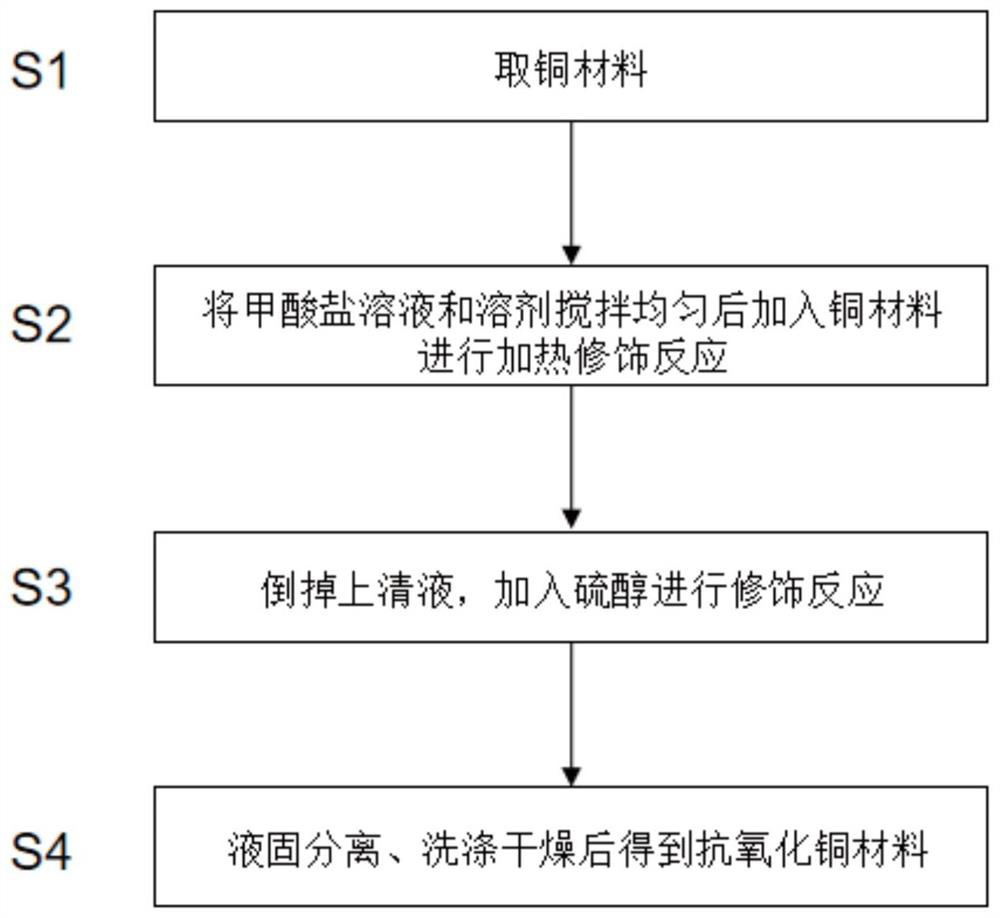

Method used

Image

Examples

Embodiment 1

[0056] Weigh 2 g of spherical copper powder with a particle size of 10 nm. Add 20 mL of butanol, 1.5 mL of oleylamine, and 2 mL of potassium formate solution into the container and stir evenly. Then put the copper powder in the container containing the above mixed solution and heat and stir at 80° C. for 1 h. After natural cooling, discard the supernatant, and then add 20mL concentration of 1.0×10 -1 mol / L mercaptoethanol and stirred for 30s. After suction filtration and drying, the anti-oxidation copper powder can be obtained. Add 0.4g of amino resin and 0.6g of ammonium chloride mixed solvent to the obtained anti-oxidation copper powder, and stir evenly in a natural environment at room temperature for 5 minutes to obtain a conductive paste with a resistivity of 1.4×10 -6 Ω·m.

Embodiment 2

[0058] Weigh 2 g of flake copper powder with a particle size of 500 nm. Add 30 mL of propylene glycol, 1 mL of n-octylamine, and 1 mL of magnesium formate solution into the container and stir evenly. Then the washed copper powder was placed in a container containing the above mixed solution, heated and stirred at 100° C. for 3 h. After natural cooling, discard the supernatant, and then add 20mL concentration of 1.0×10 -3 mol / L cysteine and stirred for 10 min. After suction filtration and drying, formate and thiol co-modified anti-oxidation copper powder can be obtained. Add 0.3g of epoxy resin and 0.7g of phenalkamine mixed solvent to the modified copper powder, and stir evenly for 6 minutes in a natural environment at room temperature to obtain a conductive paste with a resistivity of 1.2×10 -6 Ω·m.

Embodiment 3

[0060] Take a piece of copper foil with a thickness of 18 μm, ultrasonicate it in glacial acetic acid for 10 minutes, wash the surface impurities and organic matter, and dry it for later use. Add 30mL of ethylene glycol, 2mL of dodecylamine, and 3mL of sodium formate solution into the container and stir evenly. Then the washed copper foil was placed in a container containing the above mixed solution and heated at 120°C for 1.5h. After natural cooling, discard the supernatant, and then add 30mL concentration of 1.0×10 -2 mol / L dodecanethiol was allowed to stand for 1 min. Take it out and dry it to get the oxidation-resistant copper foil co-modified with formate and thiol, and immediately test the resistivity, which is 1.8×10 -8 Ω·m. The resistivity is still 1.8×10 after being exposed to the air for 30 days -8 Ω·m.

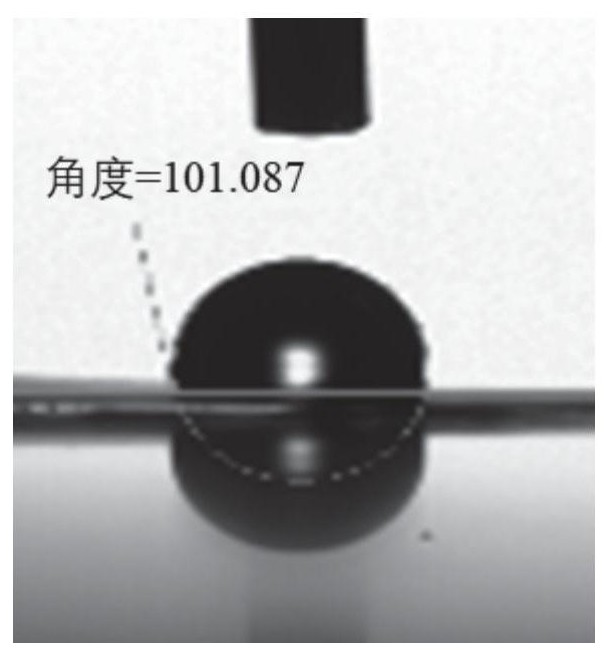

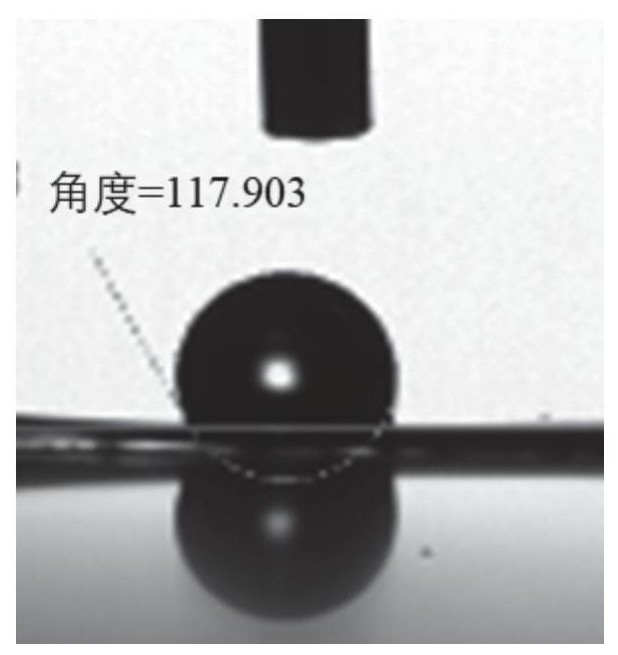

[0061] refer to Figure 2a , Figure 2b , Figure 2c and 2d , Figure 2a It is the test chart of the surface contact angle of copper foil when it is not m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com