Preparation method, product and application of low-temperature phosphorus-doped carbon nitride loaded high-dispersion palladium hydrogen evolution catalyst

A technology of phosphorus doping and carbon nitride, which is applied in the field of hydrogen evolution catalyst preparation, can solve the problems of high requirements for substrate materials and experimental equipment, uneven particle dispersion, and restrictions on wide application, so as to improve photocatalytic performance and simple preparation method , Improve the effect of Schottky barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

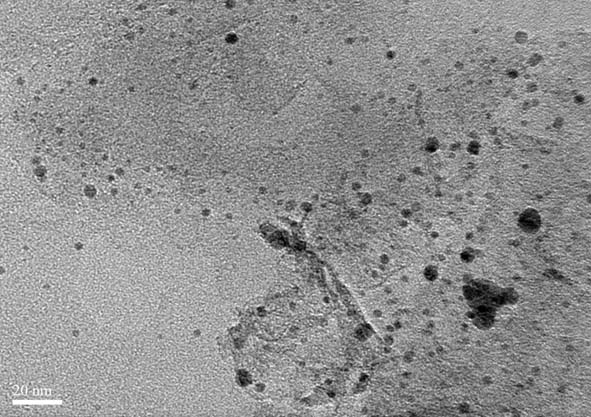

Image

Examples

Embodiment 1

[0031] A low-temperature phosphorus-doped carbon nitride-supported hydrogen evolution catalyst with highly dispersed palladium is prepared according to the following steps:

[0032] 1), preparation of phosphorus-doped carbon nitride:

[0033] a) Weigh melamine, hydroxyethylidene diphosphonic acid, ethylene glycol and deionized water, wherein the mass ratio of melamine and hydroxyethylidene diphosphonic acid is 1: 0.4, and the mass ratio of melamine and deionized water is 1 :100; the mass ratio of ethylene glycol to deionized water is 1:10, first add melamine and hydroxyethylidene diphosphonic acid to the mixed solution of deionized water and ethylene glycol, heat to 80°C and stir to evaporate it dry; then,

[0034] b) Put the above white solid into a ceramic crucible, bake in a muffle furnace at 500 °C for 4 h, and then cool naturally to obtain phosphorus-doped carbon nitride powder.

[0035] 2), preparation of phosphorus-doped carbon nitride supported Pd metal particles:

...

Embodiment 2

[0040] A low-temperature phosphorus-doped carbon nitride-loaded hydrogen evolution catalyst with highly dispersed palladium, similar to Example 1, prepared according to the following steps:

[0041] 1), preparation of phosphorus-doped carbon nitride:

[0042] a), weigh melamine, hydroxyethylidene diphosphonic acid, ethylene glycol and deionized water, wherein the mass ratio of melamine and hydroxyethylidene diphosphonic acid is 1:0.1, and the mass ratio of melamine and deionized water is 1 :200, the mass ratio of ethylene glycol to deionized water is 1:5; first add melamine and hydroxyethylidene diphosphonic acid to the mixed solution of deionized water and ethylene glycol, heat to 100 ℃ and stir to evaporate it dry to obtain a white solid; then,

[0043] b) Put the white solid above into a ceramic crucible, bake it in a muffle furnace at 600 °C for 3 h, and then cool it down naturally to obtain phosphorus-doped carbon nitride powder.

[0044] 2), preparation of low-temperat...

Embodiment 3

[0048] A low-temperature phosphorus-doped carbon nitride-loaded hydrogen evolution catalyst with highly dispersed palladium, similar to Example 1, prepared according to the following steps:

[0049] 1), preparation of phosphorus-doped carbon nitride:

[0050] a), take melamine, hydroxyethylidene diphosphonic acid, ethylene glycol and deionized water, wherein, the mass ratio of melamine and hydroxyethylidene diphosphonic acid is 1:0.2, and the mass ratio of melamine and deionized water is 1:500, the mass ratio of ethylene glycol to deionized water is 1:1; first add melamine and hydroxyethylidene diphosphonic acid to the mixed solution of deionized water and ethylene glycol, heat to 90 ℃ and stir to It was evaporated to dryness to give a white solid; then,

[0051] b) put the above white solid into a ceramic crucible, bake it in a muffle furnace at a temperature of 550°C for 5 hours, and then naturally cool to obtain phosphorus-doped carbon nitride powder;

[0052] 2), prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com