Multilayer composite graphene electromagnetic shielding material and preparation method thereof

An electromagnetic shielding material and multi-layer composite technology, applied in the fields of magnetic/electric field shielding, coating, electrical components, etc., can solve the problems of high cost, low environmental tolerance, heavy weight, etc., and achieve low cost and high processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

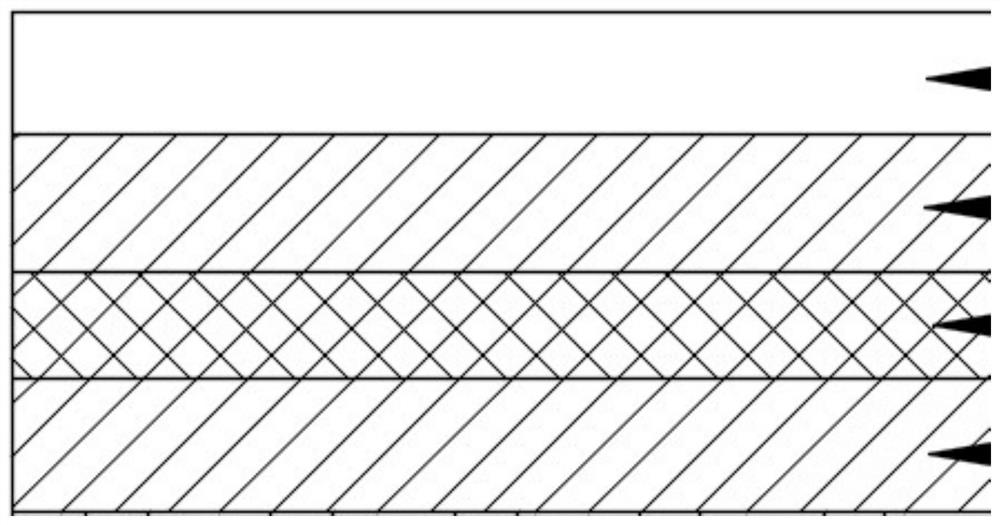

[0033] Select long multi-walled carbon nanotube powder, add deionized water, ultrasonically disperse for 1 hour, and prepare a 10% carbon nanotube water-based slurry; add 1M concentrated sulfuric acid, heat and acidify at 60°C for 1 hour, and then stand and cool for 1 hour; high-speed centrifugation, Wash 5 times with deionized water; add dilute hydrochloric acid for 1 hour, repeat 5 times with deionized water; add deionized water to the acidified multi-walled carbon nanotubes after washing, and disperse ultrasonically until they stand for 30 minutes without aggregation; acidify in the same way Few-layer graphene powder, then add nano-ferric oxide particles, and ultrasonically disperse with deionized water until it stands for 30 minutes without coagulation; figure 1 The structure shown is formed by suction filtration; finally, the third-generation water-based polyurethane coating is evenly coated on the surface of the second layer, and the finished product is obtained after cur...

Embodiment 2

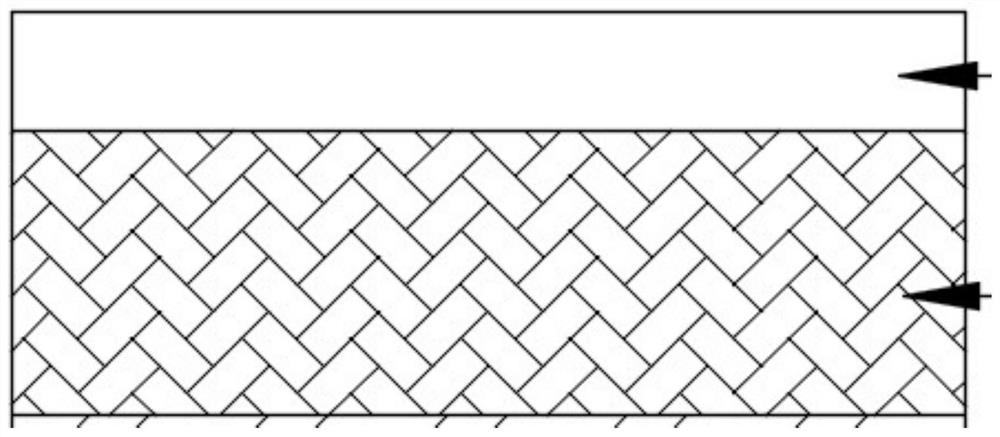

[0035] Add long multi-wall carbon nanotube powder and few-layer graphene powder into deionized water, ultrasonically disperse for 1 hour, and prepare a 10% aqueous slurry. Mix the above slurry with the same quality, ultrasonically disperse for 1 hour; add 1M Concentrated sulfuric acid, heating and acidifying at 60°C for 1 hour, then standing and cooling for 1 hour; high-speed centrifugation, washing with deionized water 5 times; adding dilute hydrochloric acid for 1 hour, repeating deionized water washing 5 times; adding nanometer four Ferric oxide particles and deionized water, ultrasonic dispersion, until standing for 30min without coagulation; figure 2 The structure shown is formed by suction filtration; finally, the third-generation water-based polyurethane coating is evenly coated on the surface of the second layer, and the finished product is obtained after curing.

[0036] The thickness of the water-based polyurethane solidified layer of the composite material is 0.05-...

Embodiment 3

[0038] Select long multi-wall carbon nanotube powder and few-layer graphene powder, add deionized water, ultrasonically disperse for 1 hour, prepare 10% water-based slurry, add ferric chloride solution, and put it into a Teflon-lined reactor The hydrothermal reaction was carried out in the medium; the hydrothermal reaction product was centrifuged and washed with deionized water at high speed, and then deionized water was added for ultrasonic dispersion until it stood for 30 minutes without coagulation; figure 2 The structure is formed by suction filtration; finally, the third-generation water-based polyurethane coating is evenly coated on the surface of the second layer, and the finished product is obtained after curing.

[0039] The thickness of the water-based polyurethane solidified layer of the composite material is 0.05-0.1mm, the thickness of the second layer of carbon-based hybrid shielding layer is 0.25-0.3mm, the thickness of the third layer of fabric base is 0.028mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com