Engineering bacterium for producing guanidinoacetic acid as well as construction method and application thereof

A technology of guanidinoacetic acid and a construction method, applied in the biological field, can solve the problems of low conversion rate and yield of guanidinoacetic acid, difficult to apply to industrial production, and high cost of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

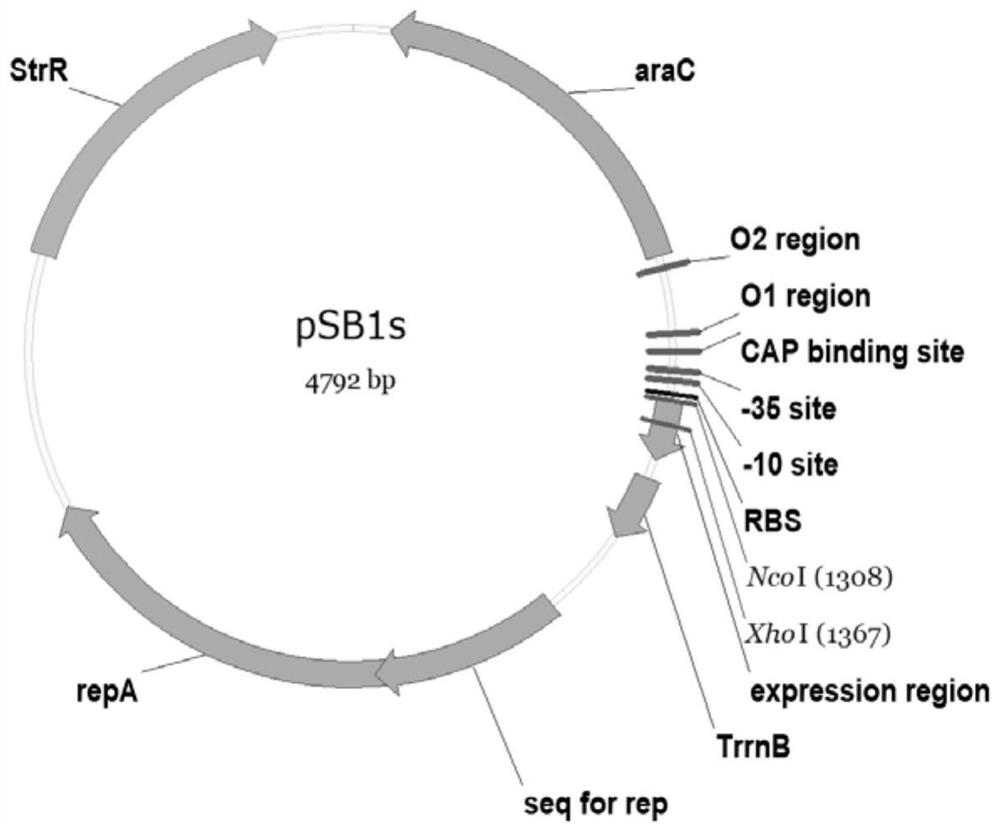

[0088] Embodiment 1, construct the genetically engineered bacterium that produces guanidinoacetic acid

[0089]1. Construction of co-expression of glutamine synthetase and L-arginine: glycine amidinyl transferase recombinant plasmid and co-expression of ornithine carbamoyl transferase, arginyl succinate synthase, arginyl succinate cleavage Enzyme, aspartate ammonia lyase recombinant plasmid

[0090] 1. Construction of recombinant plasmid pL01 expressing glutamine synthetase

[0091] According to the nucleotide sequence GenBank: AF005635.2 (amino acid sequence GenBank: WP_003859638.1) of glutamine synthetase (GS) of Corynebacterium glutamicum (Corynebacterium glutamicum), primers (P1 and P2) were designed to amplify glutamine The gene encoding amide synthetase (glnA) has a fragment size of about 1200bp, which is consistent with the target fragment. The sequencing results show that the sequence of the amplified fragment is correct, and the fragment is used to construct the reco...

Embodiment 2

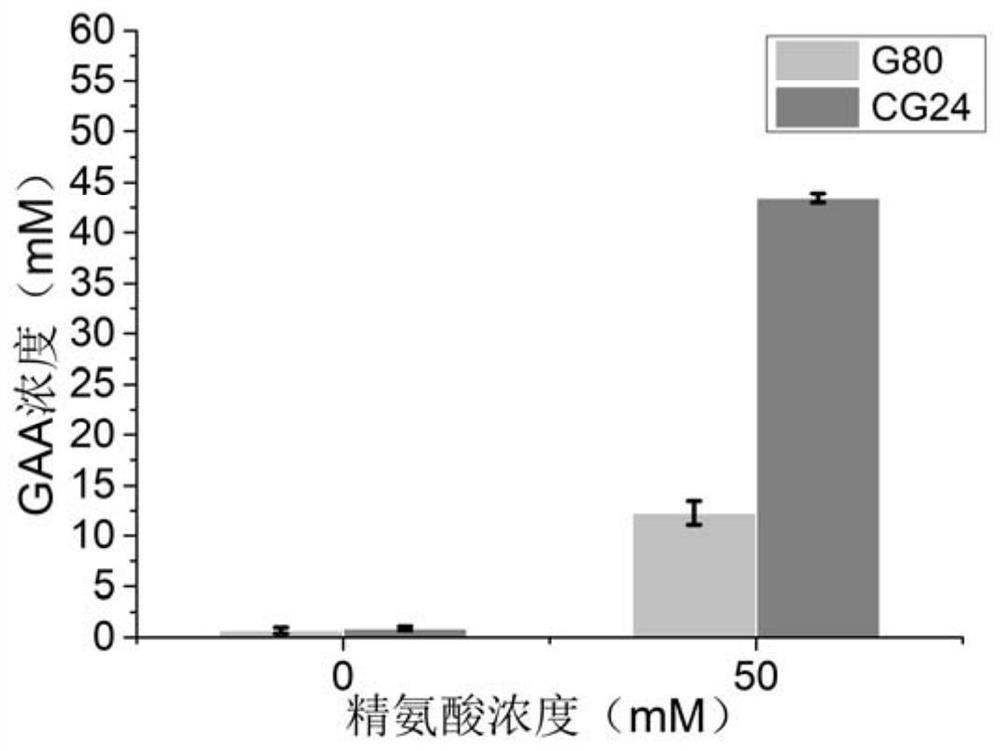

[0165] Embodiment 2, utilize the guanidinoacetic acid gene engineering bacterium that produces guanidinoacetic acid to prepare guanidinoacetic acid

[0166] 1. Induction of genetically engineered bacteria producing citrulline, arginine and guanidinoacetic acid respectively

[0167] Step-by-step induction in 2YT medium: Streak the metabolic genetically engineered bacteria CG24 producing guanidinoacetic acid onto an LB plate containing 1.5% agar powder, 50 μg / mL ampicillin and 50 μg / mL streptomycin On, shake overnight at 37°C, rotate at 200rpm; inoculate the overnight culture into 2YT medium with an inoculation volume of 1% by volume, and shake at 37°C for 2-3h to OD 600 After 0.5-0.8, add L-arabinose with a final concentration of 0.02% mass fraction, culture at 30° C. and 200 rpm for 12 hours. After the induced cells, according to the growth of the bacterial liquid, take a certain amount of bacterial cells, centrifuge at 4°C, 8000rpm for 10 minutes, and use ultrasonic waves to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com