High-oxygen-resistant medium-temperature hydrolysis catalyst and preparation method thereof

A hydrolysis catalyst and catalyst technology, which is applied in the field of coal chemical industry, can solve problems such as inability to solve hydrolysis problems, and achieve good hydrothermal stability, no increase in system resistance, and no loss of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

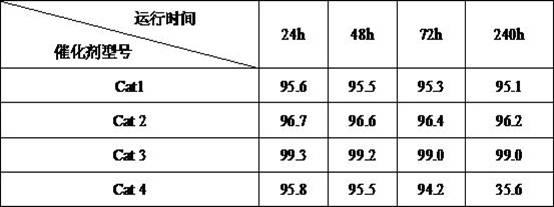

Examples

Embodiment 1

[0021] 35g metatitanic acid, 28g alkaline silica sol (SiO 2 Content 25%), 56g pyrolusite (MnO 2 Content 50%), 3g of template agent pentaerythritol and 1000ml of deionized water were mixed evenly, then moved into a high-pressure synthesis kettle and sealed, and crystallized for 24h under the conditions of a pressure of 9.0MPa and a temperature of 220°C; Adjust the pH value to 10, add 29.6g of lithium nitrate, 24.1g of ammonium metatungstate, 2.9g of cesium acetate and 17.6g of copper nitrate into the reaction kettle, and carry out ion exchange reaction at a temperature of 80°C for 4h ; Then add the above slurry to PSAA (polysilicate flocculant) for precipitation, filter, and collect the filtrate after filtration for the next reaction. After the filter cake is washed and dried, it is extruded into strips, dried at 150°C for 2 hours, and roasted at 700°C for 3 hours. A medium-temperature hydrolysis catalyst resistant to high oxygen is obtained. The specific surface area of th...

Embodiment 2

[0023] 47.4g metatitanic acid, 47.4g alkaline silica sol (SiO 2 content 25%), 39.5g pyrolusite (MnO 2 Content 50%), 2g of template agent tetrapropylammonium hydroxide and 1000ml of deionized water are mixed evenly, then moved into a high-pressure synthesis kettle and sealed, and crystallized for 48h at a pressure of 9.0MPa and a temperature of 320°C; The amine adjusts the pH value of the crystal slurry to 10, and adds 59.2g of lithium nitrate, 12.0g of ammonium metatungstate, 1.45g of cesium acetate and 11.7g of copper nitrate to the reaction kettle, and at a temperature of 80°C, Carry out ion exchange reaction for 8 hours; then add the above slurry to the flocculant PPFC (polyphosphorus ferric chloride) to precipitate and filter, after filtration, the filtrate is collected for the next reaction, the filter cake is washed and dried, extruded into strips, and dried at 120°C 4h, 500°C calcined for 4h to obtain a high-oxygen-resistant medium-temperature hydrolysis catalyst. The...

Embodiment 3

[0025] 53.6g metatitanic acid, 61.2g alkaline silica sol (SiO 2 content 25%), 61.2g pyrolusite (MnO 2Content 50%), 5g of template agent cetyltrimethylammonium bromide and 1000ml of deionized water were mixed evenly, then moved into a high-pressure synthesis kettle and sealed, and crystallized at a pressure of 9.0MPa and a temperature of 270°C for 36h ; The pH value of the crystal slurry is adjusted to 10 with triethylamine, and the lithium nitrate of 49.3g, the ammonium metatungstate of 18.1g, the cesium acetate of 0.72g and the cupric nitrate of 8.8g are added in the reactor, at a temperature of 80 Under the condition of ℃, ion exchange reaction was carried out for 6 hours; then the above slurry was added to the flocculant PPAC (polyphosphorus aluminum chloride) to precipitate and filtered, and the filtrate was collected after filtration for the next reaction, and the filter cake was washed and dried and extruded into strips. After drying at 100°C for 3 hours and calcining a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com