Method for comprehensive recovery of valuable metal from copper-based solid waste

A valuable metal and copper-based technology, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of high equipment requirements, high energy consumption, unsuitable for industrial applications, etc., achieve strong applicability and reduce leaching costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

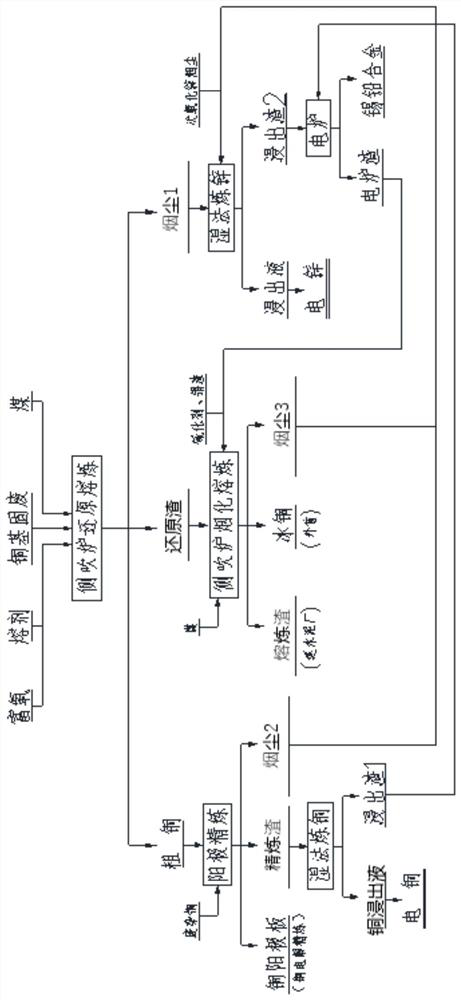

Image

Examples

Embodiment 1

[0047] The mass percentage of Cu in the copper-based solid waste used in this embodiment is 19.5%, Pb 3.2%, Zn 3.5%, and Sn 3.5%; the mass percentage of carbon in coal is 75%, and the ash content is less than 10%; The flux includes quartz stone and limestone, of which more than 90% is quartz stone, and SiO in quartz stone 2 The mass percentage is 85.5%, and the CaO content in the limestone is 51.3%; the purchased scrap copper contains 80% Cu, Pb 2.5%, Zn 6%, Sn 10%, and the vulcanizing agent contains S 31.3%, Zn 1.3%, FeO61 .5%, tin slag contains Sn 4.5%, Pb 2.6%, Cu 3.5%, Zn 2.5%, sub-zinc oxide fume contains Zn 55%, Pb 2.5%, FeO 20.2%.

[0048] Such as figure 1 As shown, 100kg of copper-based solid waste, 15kg of coal, and 5kg of flux are evenly mixed and batched, and then added to the oxygen-enriched side-blown furnace for reduction and smelting. Blow into the oxygen-enriched concentration with an oxygen concentration of 65%. The oxygen-enriched concentration is the conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com