Solid electrolyte and preparation method thereof, and lithium secondary solid-state battery

A solid electrolyte, lithium salt technology, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, secondary battery and other directions, can solve the problems of complex preparation method and high cost, achieve simple preparation process, high production efficiency, and improve energy density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the solid electrolyte of the present invention comprises the following steps:

[0051] a, mixing the polymer substrate, lithium salt and additives to obtain a slurry;

[0052] b. The slurry is formed into a film, and then dried to obtain a solid electrolyte;

[0053] In one embodiment, step a can specifically adopt the following method:

[0054] (1) Select polymer substrates, additives, and select a certain quality of solvents, including but not limited to NMP, DMF, etc., calculated by mass ratio, controlled at 60% to 85% of the total amount of slurry;

[0055] (2) adding the polymer substrate into the solvent, and stirring at room temperature for 1 to 2 hours to form a stable and uniform transparent colloid;

[0056] (3) Ultrasonic disperse the additive in a solvent whose total mass of the slurry is 10% for 10 minutes to 1 hour.

[0057] (4) Add the supersonicated additive and lithium salt directly to the glue solution prepared in step (2),...

Embodiment 1

[0064] Synthesis of Ta-doped β-LiAlSi 2 o 6 , the synthesis steps are as follows:

[0065] (1) LiOH·H with a mass percentage of 28.7% 2 O, 65.7% montmorillonite, 5.6% tantalum oxide were stirred in 20ml (when the montmorillonite was 7.1g) in isopropanol for 24 hours and dried.

[0066] (2) Grind the lumps dried in step (1) into powder, place them evenly in a crucible, and burn them in air at 900° C. for 9 hours with a heating rate of 5° C. / min.

[0067] (3) The powder sample completed by burning paper in step (2) was ball milled 30 times at a speed of 800r / min, each time being 5min, to obtain β-LiAlSi doped with Ta 2 o 6 ,spare.

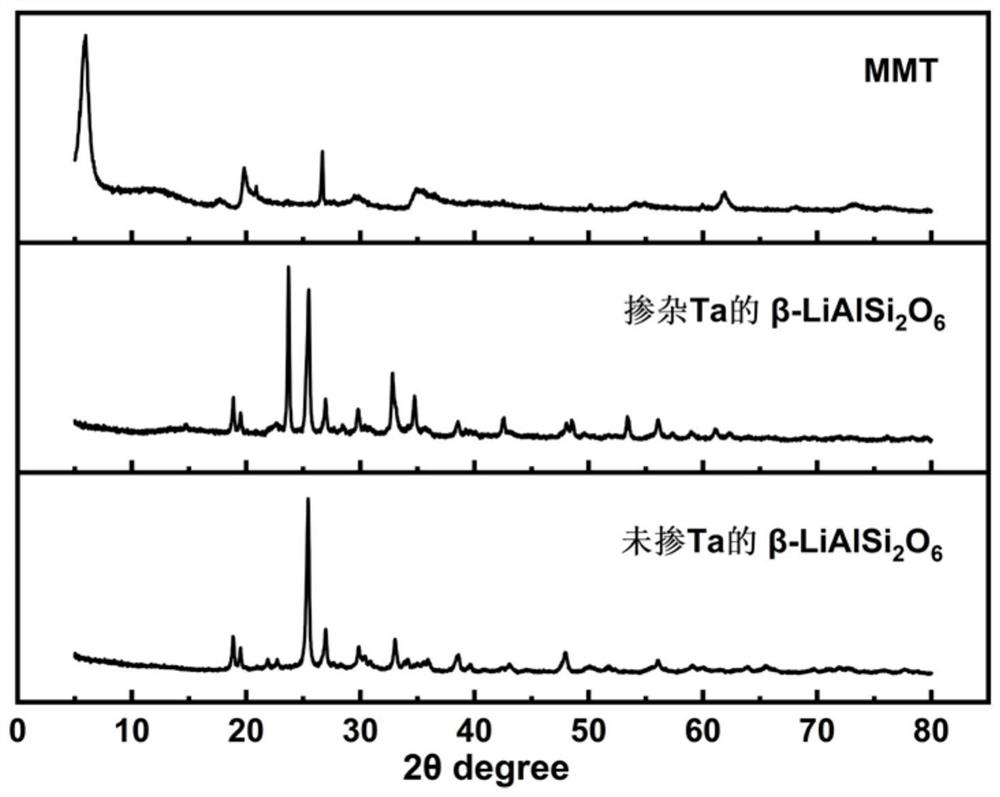

[0068] The Ta-doped β-LiAlSi 2 o 6 See the XRD pattern of figure 1 . figure 1 Among them, MMT is the XRD pattern of montmorillonite. From figure 1 It can be seen that the peaks at 23.7° and 25.48° are Ta-doped β-LiAlSi 2 o 6 The two most obvious characteristic peaks of XRD show that the present invention has successfully prepared Ta-dope...

Embodiment 2

[0096] Referring to the preparation method of Example 1, the composition of the solid electrolyte is changed, and the solid electrolyte is composed of the following components in mass percentage: 65% of the polymer substrate; 25% of the lithium salt; 10% of the additive; wherein, the polymer substrate is Polyvinylidene fluoride (PVDF), lithium salt is LiTFIS, additive is β-LiAlSi doped with Ta 2 o 6 .

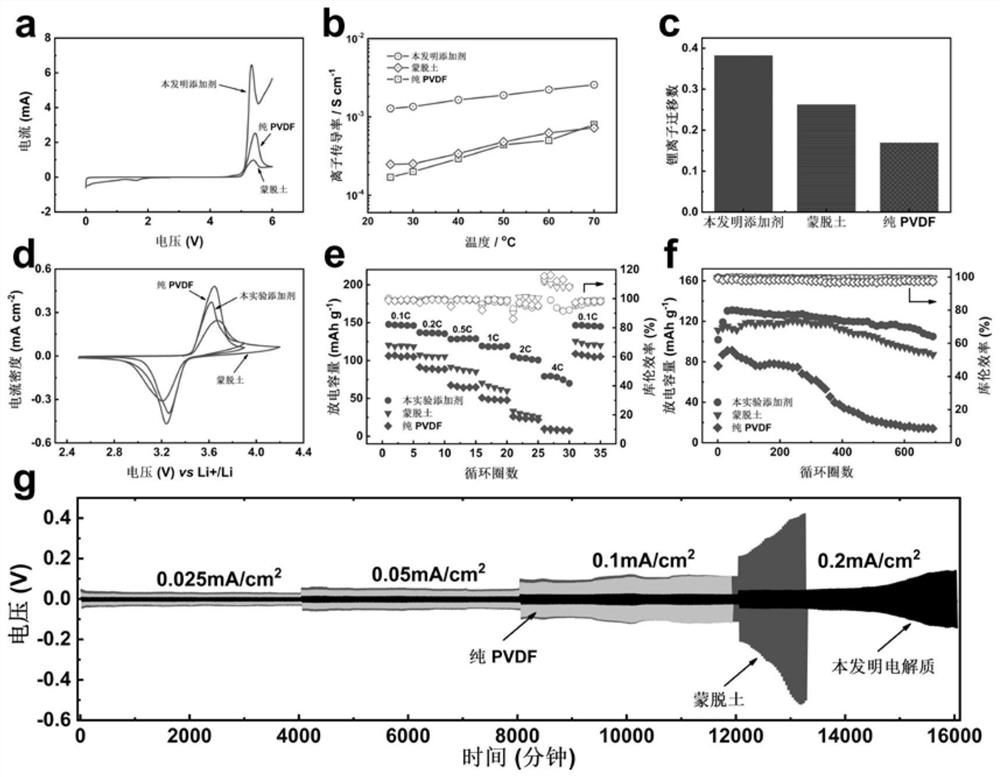

[0097] Using this solid electrolyte to form a battery, the first charge and discharge capacity is 150mAh / g at a rate of 0.1C. According to the picture of the rate performance, the capacity is also close to 150mAh / g at 35 cycles, and the Coulombic efficiency is close to 100%; at a rate of 0.5C , the first cycle capacity is 100mAh / g, but it will quickly rise to 130mAh / g after 2-3 cycles, the capacity is close to 135mAh / g at 40 cycles, and the capacity is still 110mAh / g after 600 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com