A preparation method of fine-grained high-purity aluminum-silicon-copper alloy target blank for sputtering

An aluminum-silicon intermediate alloy and alloy target technology, which is applied in the field of sputtering targets, can solve problems such as device failure, and achieve the effects of uniform structure, uniform composition and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

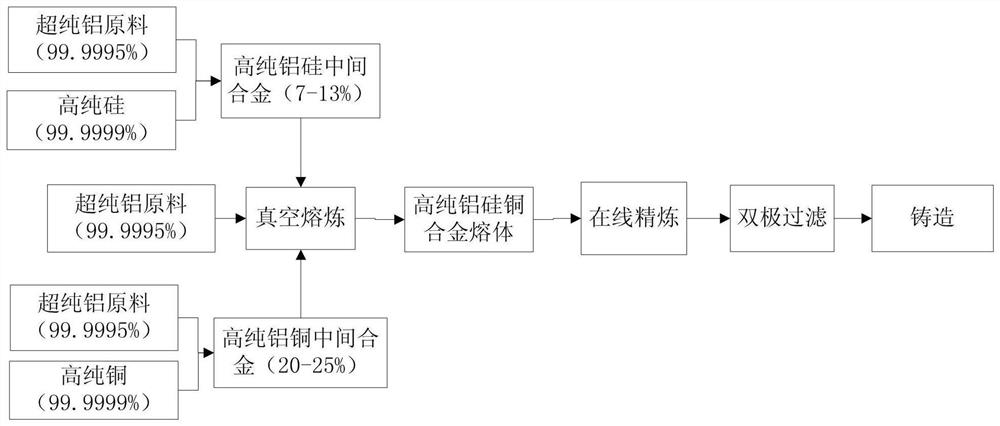

Method used

Image

Examples

Embodiment 1

[0063] (1) Master alloy preparation:

[0064] The master alloy is configured by using ultra-pure aluminum raw materials with a purity of 99.9995wt% and high-purity silicon with a purity of 99.9999wt%. The raw materials are put into the vacuum melting furnace with the aluminum-silicon weight ratio of 88:12. The high-purity silicon raw material is broken into powder blocks and added to accelerate the melting of silicon. After the vacuum melting furnace is evacuated, the temperature is raised for smelting. After the aluminum ingot is completely melted, the temperature of the molten aluminum is controlled at 830°C and kept for 1 hour. A graphite rotor was used to stir the molten aluminum for 15 minutes to homogenize the composition, and cast it into a remelted ingot of AL-13wt% Si master alloy (there was burning loss during the melting process, and the actual ratio was mainly based on the detected ratio).

[0065]The master alloy is configured by using ultra-pure aluminum raw ma...

Embodiment 2

[0073] (1) Master alloy preparation: the same as in Example 1.

[0074] (2) Melting: sawing the above-mentioned aluminum-silicon and aluminum-copper master alloy ingots into small pieces. First, 80wt% is added to a vacuum melting furnace, and the temperature is raised and melted after vacuuming. After the aluminum ingot is completely melted, control the temperature of the molten aluminum to 730-745°C and use heat preservation to stand for 20 minutes. Sampling was carried out using a photoelectric direct-reading spectrometer, and the Si content in the molten aluminum was determined to be 0.80wt%, and the copper content was 0.41wt%. Add the remaining 20wt% of the master alloy twice, repeat the smelting process, and take samples to determine that the Si content in the molten aluminum is 1.0wt%, and the copper content is 0.51wt%. After casting, the bar was sampled to detect the content of metal impurity elements, using a glow discharge mass spectrometer, and the detection data a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com