Antiferroelectric material and preparation method thereof, and capacitor containing antiferroelectric material

An anti-ferroelectric and capacitor technology, applied in the field of anti-ferroelectric thick film capacitors, can solve the problems of reduced service life, few, destruction, etc., and achieve excellent energy storage performance, strong breakdown resistance, and high energy storage density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The present embodiment provides an antiferroelectric thick film capacitor comprising (Pb 0.94 La 0.04 )(Zr 0.48 sn 0.45 Ti 0.07 )O 3 (abbreviation PLZST-1) represents the antiferroelectric material, the preparation method of this antiferroelectric rear film capacitor comprises the steps:

[0054] S1: Preparation of PLZST-1 casting powder;

[0055] S2: Preparation of PLZST-1 casting slurry and thick film; wherein, in the casting slurry, the mass fraction of PLZST-1 casting powder is 65%, the mass fraction of solvent ethanol / xylene is 20%, and the dispersion The mass fraction of the agent ethoxylate is 2%, the mass fraction of the binder polyvinyl alcohol is 7%, the mass fraction of the plasticizer dibenzoate is 4%, and the mass fraction of the homogenizer cyclohexanone is 2%. %;

[0056] S3: Preparation of PLZST-1 antiferroelectric thick film capacitor;

[0057] Step S1 specifically includes the following steps:

[0058] S101: According to the chemical formula (...

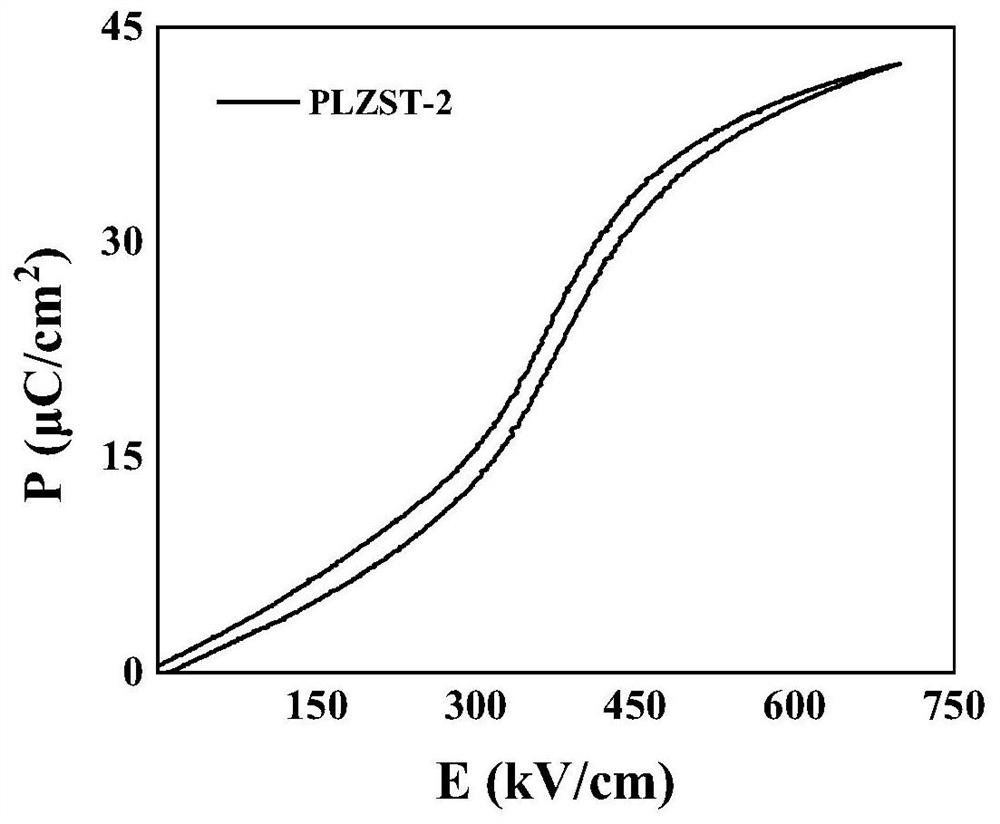

Embodiment 2

[0077] The present embodiment provides an antiferroelectric thick film capacitor comprising (Pb 0.94 La 0.04 )(Zr 0.67 sn 0.30 Ti 0.03 )O 3 (abbreviation PLZST-2) represents the antiferroelectric material, and the preparation method of this antiferroelectric rear film capacitor comprises the steps:

[0078] S1: Preparation of PLZST-2 casting powder;

[0079] S2: Preparation of PLZST-2 casting slurry and thick film; wherein, in the casting slurry, the mass fraction of PLZST-2 casting powder is 55%, the mass fraction of solvent toluene / ethanol is 30%, and the dispersant The mass fraction of herring fish oil is 1.5%, the mass fraction of binder ethyl cellulose is 6%, the mass fraction of plasticizer polyethylene glycol / phthalate is 5%, and the mass fraction of homogenizer cyclohexanone The mass fraction is 2.5%;

[0080] S3: Preparation of PLZST-2 antiferroelectric thick film capacitor;

[0081] Step S1 specifically includes the following steps:

[0082] S101: According ...

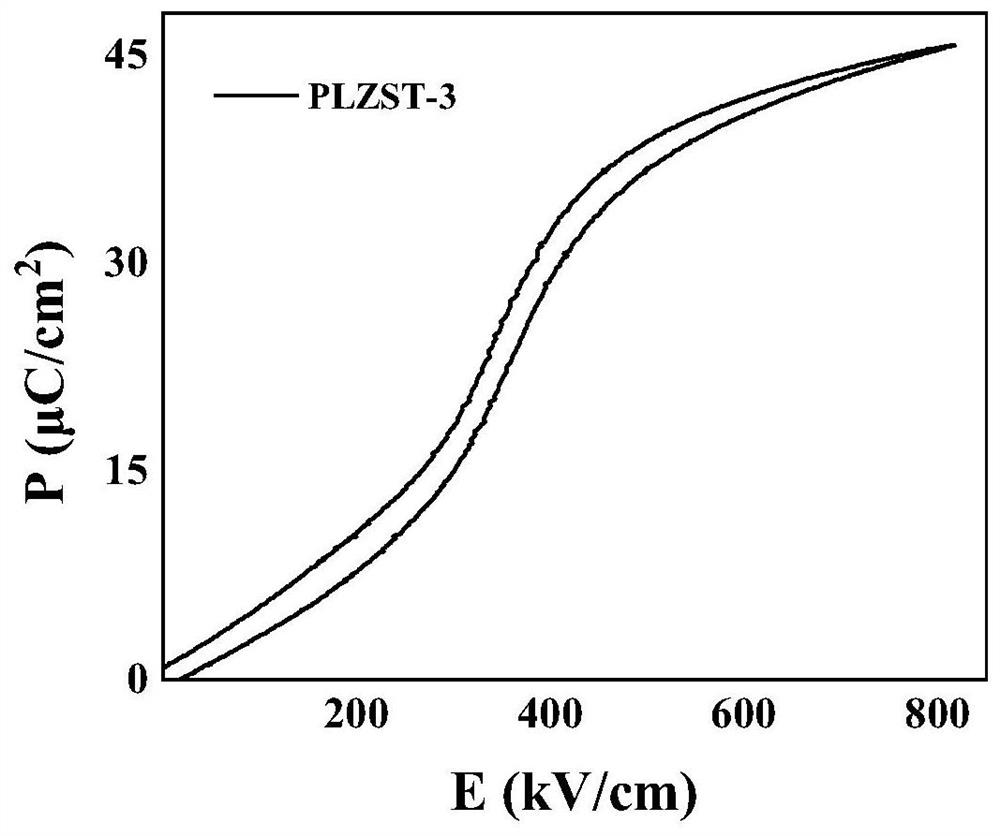

Embodiment 3

[0101] The present embodiment provides an antiferroelectric thick film capacitor comprising (Pb 0.94 La 0.04 )(Zr 0.49 sn 0.50 Ti 0.01 )O 3 (abbreviation PLZST-3) represents the antiferroelectric material, and the preparation method of this antiferroelectric rear film capacitor comprises the steps:

[0102] S1: Preparation of PLZST-3 casting powder;

[0103] S2: Preparation of PLZST-3 casting slurry and thick film; wherein, in the casting slurry, the mass fraction of PLZST-3 casting powder is 60%, the mass fraction of solvent toluene / ethanol is 30%, and the dispersant The mass fraction of tributyl phosphate is 1%, the mass fraction of binder polyvinyl butyral is 5%, the mass fraction of plasticizer polyethylene glycol / phthalate is 3%, and the homogenizer The massfraction of cyclohexanone is 1%;

[0104] S3: Preparation of PLZST-3 antiferroelectric thick film capacitor;

[0105] Step S1 specifically includes the following steps:

[0106] S101: According to the chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com