Method for preparing multi-morphology nano zinc oxide by solid-phase method

A nano-zinc oxide, multi-morphology technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., to achieve the effect of easy experimental process, simple process conditions, green and environmental protection yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Weigh 11.52g of zinc sulfate heptahydrate (0.04mol) and 3.17g of ammonium bicarbonate (0.04mol) in a ceramic mortar with a diameter of 160mm. At this time, the ratio of zinc sulfate heptahydrate and ammonium bicarbonate is 1:1. Without dispersion medium;

[0042] 2. Manually grind the solid mixture for 30 minutes;

[0043] 3. After the reaction, transfer the mixture in the ceramic mortar to a 50mL centrifuge bottle, add 10mL deionized water, stir the suspension with a glass rod for 3min, then centrifuge the suspension, filter, and continue to add deionized water , repeat the steps of washing and centrifugation 3 times, to remove unreacted complete reactant (zinc sulfate heptahydrate and ammonium bicarbonate) and ammonium sulfate;

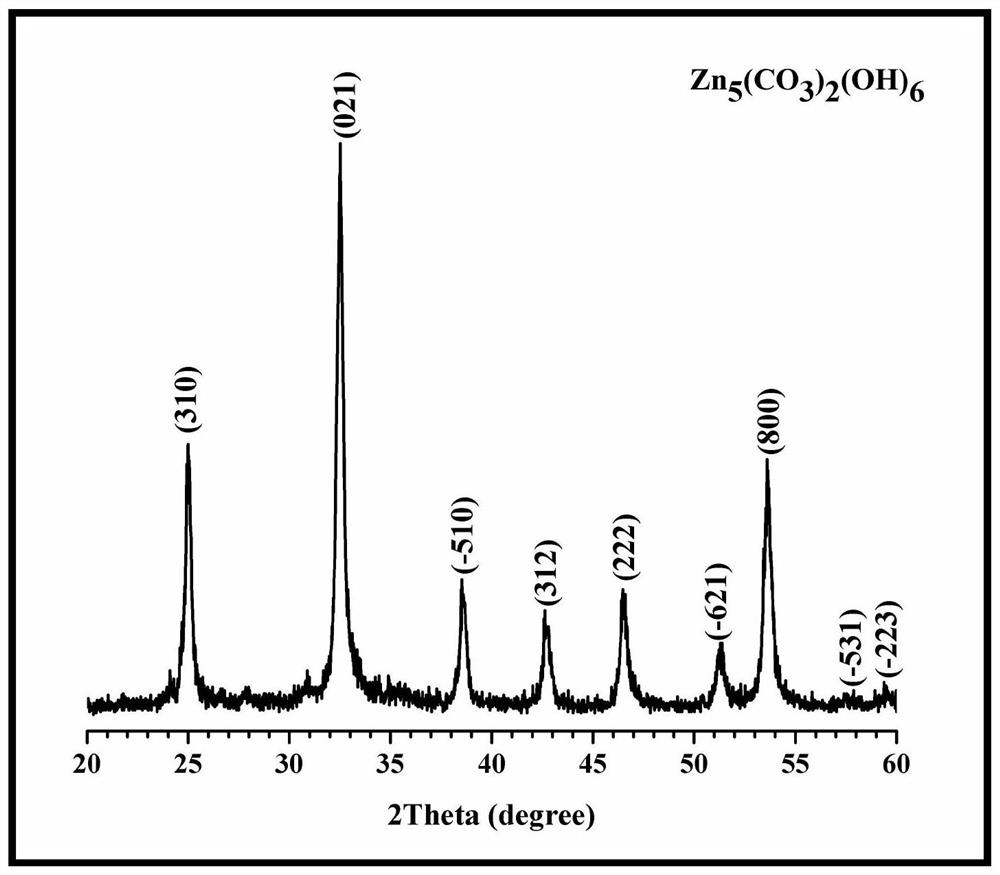

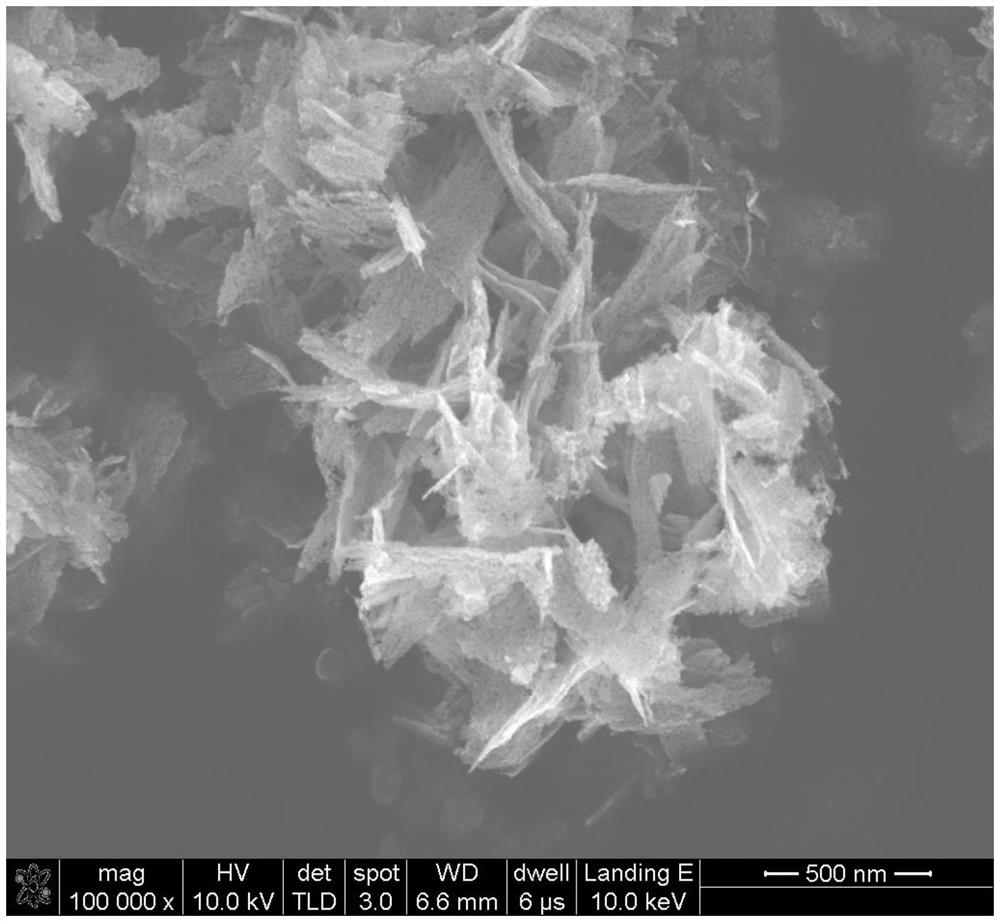

[0044] 4. Dry the centrifuged solid at 60°C for 0.5h to obtain the precursor basic zinc carbonate;

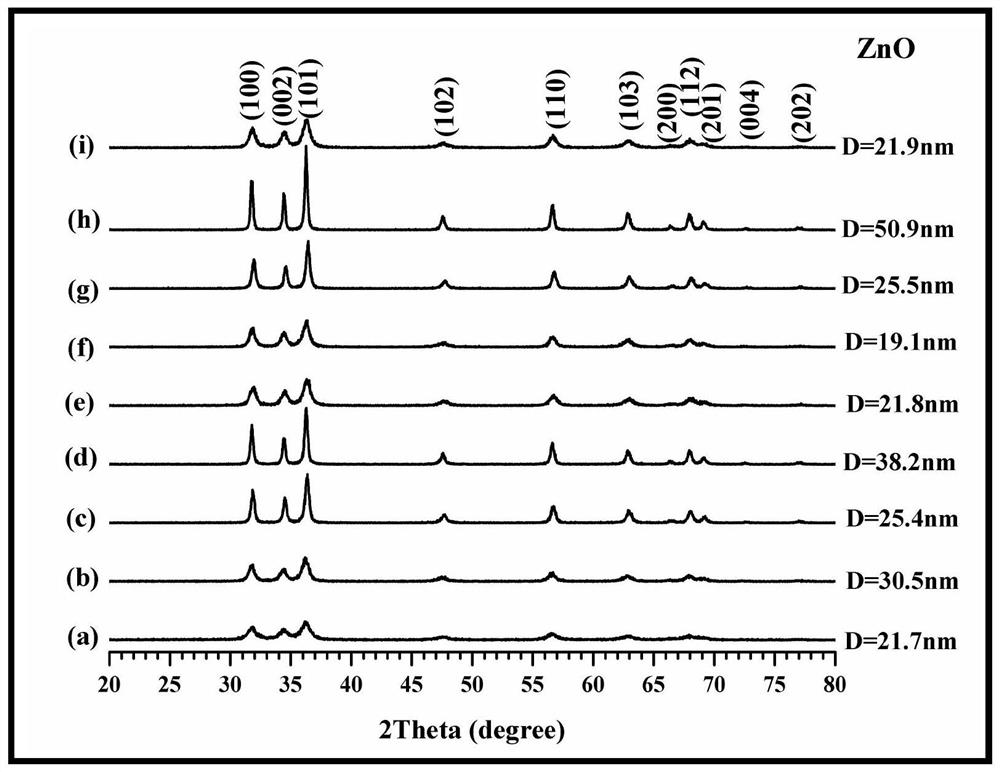

[0045] 5. Put the precursor in a muffle furnace for calcination, the calcination temperature is 300° C., and the calcination time is 1 h...

Embodiment 2

[0049] 1. Weigh 5.76g zinc sulfate heptahydrate (0.02mol) and 3.17g ammonium bicarbonate (0.04mol) in a ceramic mortar with a diameter of 160mm. At this time, the ratio of zinc sulfate heptahydrate and ammonium bicarbonate is 1:2. Add the dispersion medium, the dispersion medium is 5mL ultrapure water;

[0050] 2. Manually grind the solid mixture for 60 minutes;

[0051] 3. After the reaction, transfer the mixture in the ceramic mortar to a 50mL centrifuge bottle, add 20mL of deionized water, stir the suspension with a glass rod for 4min, then centrifuge the suspension, filter, and continue to add deionized water , repeat the steps of washing and centrifugation 4 times, to remove unreacted complete reactant (zinc sulfate heptahydrate and ammonium bicarbonate) and ammonium sulfate;

[0052] 4. Dry the centrifuged solid at 70°C for 1 hour to obtain the precursor basic zinc carbonate;

[0053] 5. Put the precursor in a muffle furnace for calcination. The calcination temperature...

Embodiment 3

[0056] 1. Weigh 3.75g of zinc sulfate heptahydrate (0.013mol) and 3.17g of ammonium bicarbonate (0.04mol) in a ceramic mortar with a diameter of 160mm. At this time, the ratio of zinc sulfate heptahydrate and ammonium bicarbonate is 1:3. Add the dispersion medium, the dispersion medium is 5mL absolute ethanol;

[0057] 2. Manually grind the solid mixture for 90 minutes;

[0058] 3. After the reaction, transfer the mixture in the ceramic mortar to a 50mL centrifuge bottle, add 30mL deionized water, stir the suspension with a glass rod for 5min, then centrifuge the suspension, filter, and continue to add deionized water , repeat the steps of washing and centrifugation 5 times, to remove unreacted complete reactant (zinc sulfate heptahydrate and ammonium bicarbonate) and ammonium sulfate;

[0059] 4. Dry the centrifuged solid at 80°C for 2 hours to obtain the precursor basic zinc carbonate;

[0060] 5. Put the precursor in a muffle furnace for calcination. The calcination tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com