Preparation method of high aromatic hydrocarbon hydrogenated resin

A technology of hydrogenated resin and high aromatic hydrocarbons, applied in the field of petroleum resin, can solve the problems of ethylene tar utilization rate, final product stability defect, complex ethylene tar components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

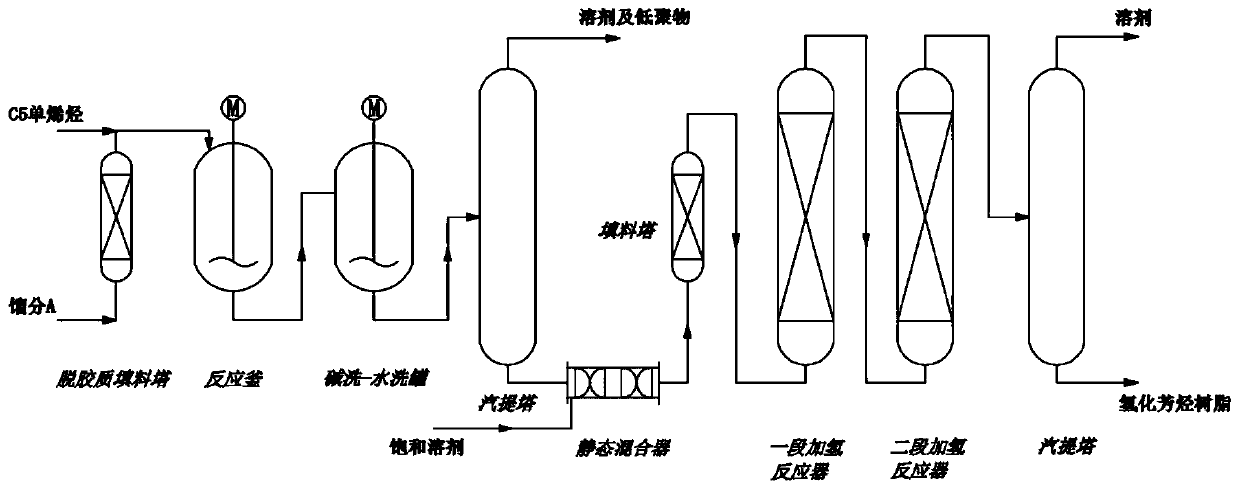

Method used

Image

Examples

Embodiment 1

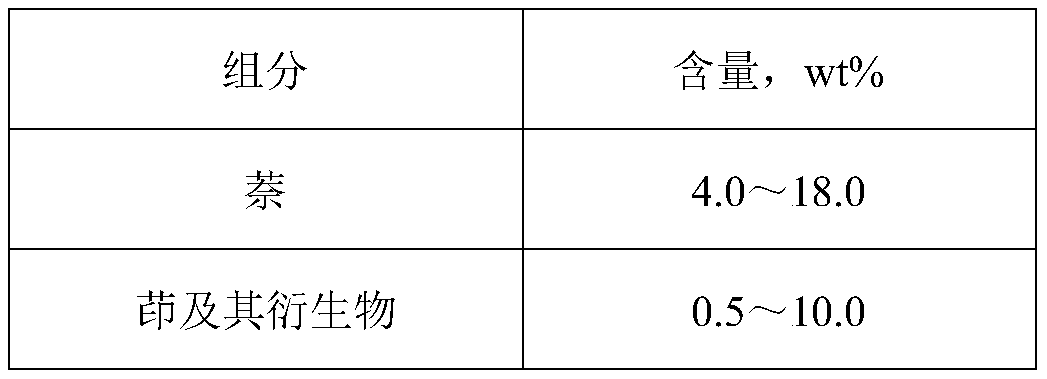

[0049] (1) Distill and cut ethylene tar to obtain Fraction A with a distillation range of 180-260°C, and pass through an alumina packing bed to reduce the colloid to 20ppm.

[0050] (2) Mix the above-mentioned fraction A with C5 monoolefins in a mass ratio of 1:0.15 to obtain ingredient B, wherein ingredient B consists of: 0.26% of 1-pentene, 1.13% of 2-pentene, 2-methyl-1-butene ene 1.87%, 2-methyl-2-butene 2.65%, cyclopentene 0.59%, methyl styrene 0.60%, dihydrodicyclopentadiene 1.04%, indene 4.27%, methyl indene 15.43%, dimethyl Indene 6.68%, naphthalene 26.51%, methylnaphthalene 9.06%, dimethylnaphthalene 4.55%, and the rest are inert components. Put 40% xylene and 0.7% boron trifluoride diethyl ether catalyst into the stirred reactor in advance, then add ingredient B dropwise at -5°C, react for 2 hours, and obtain a polymerization solution.

[0051] (3) Wash the polymerization liquid in step (2) with alkali, then wash with water to neutrality, and remove the catalyst (10...

Embodiment 2~6

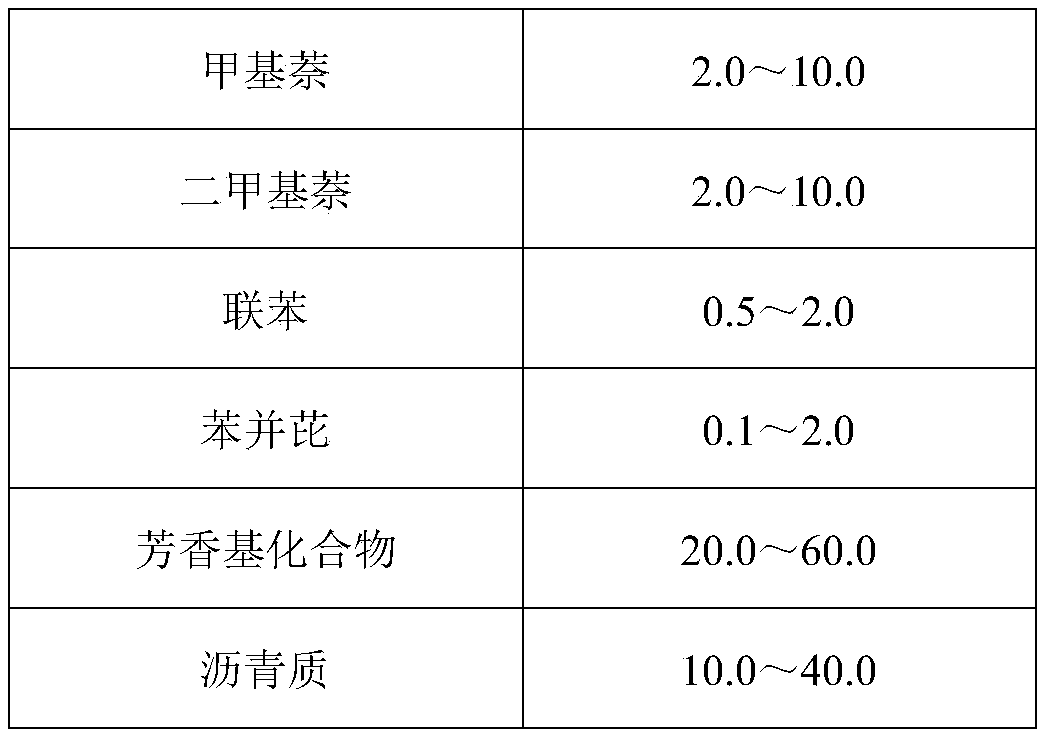

[0056] The ratio between the ethylene tar cut fraction A and the C5 monoolefins in the polymerization feed is a key factor in the process of the present invention. The following table 3 shows the effect of the main polymerizable monomers in the ingredient B after mixing the two on the performance of the resin product; other conditions are the same as in Example 1.

[0057] table 3

[0058]

[0059] From the above-mentioned Examples 2-6, it can be seen that with the increase of the total content of C5 monoolefins in the ingredient B, the softening point, Gardner color number, and aromaticity of the hydrogenated resin all decrease, while the molecular weight distribution Mw / Mn tends to increase; when the ingredient When there is no C5 monoolefin as a modifier, the hydrogenated resin has the maximum aromaticity. The hydrogenated resin has a suitable aromaticity and molecular weight distribution, which can effectively enhance the compatibility with elastomers such as SBS and S...

Embodiment 7~10

[0061] The following table 4 is based on the steps (1) to (3) of Example 1, adjusting a section of Fe-Mo / γ-Al 2 o 3 The hydrogenation catalytic process conditions were investigated to investigate its influence on the performance of the hydrogenated resin. All the other conditions are the same as in Example 1.

[0062] Table 4

[0063]

[0064] It can be known from the above Examples 7-10 that in the one-stage hydrogenation process, the hydrogenation temperature has a more obvious influence on the properties of the hydrogenated resin. The one-stage hydrogenation process can strengthen the hydrogenation depth of the hydrogenated resin, increase the thermal cracking tendency of the resin, reduce the softening point and molecular weight distribution, and decrease the aromaticity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com