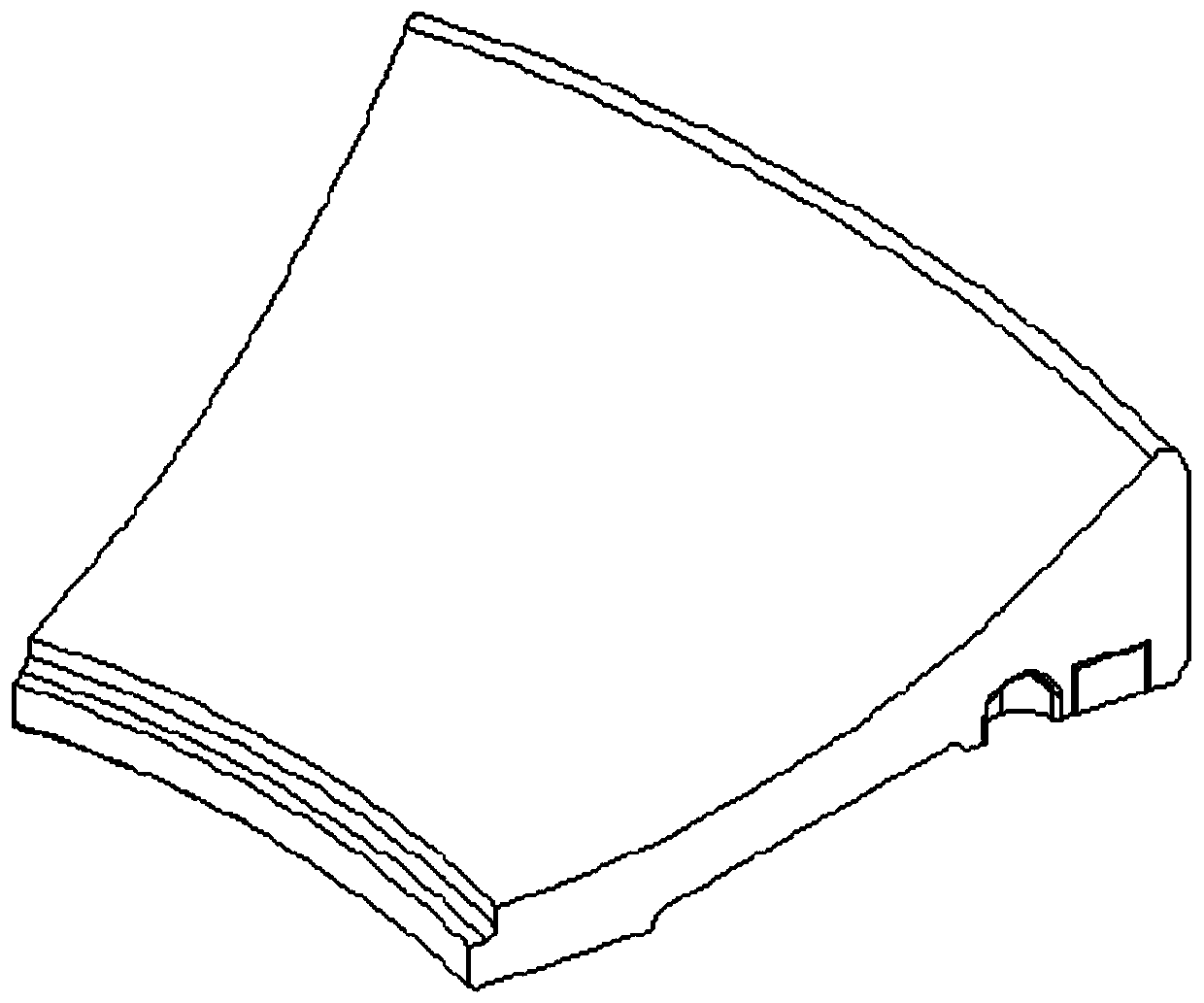

Liner plate for vertical coal grinding and crushing machine and processing technology thereof

A technology of processing technology and wear-resistant lining board, which is applied in the field of lining board for vertical coal crusher and its processing technology, can solve the problems of affecting the civilized production of modern enterprises, wasting manpower, material and financial resources, maintenance and replacement, etc. problems, to achieve the effect of improving initial hardness and overall mechanical properties, improving efficiency, and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The liner is composed of the following components in mass fraction: 2.4-3.2%C, ≤1.0%Si, 0.5-1.5%Mn, 18.0-23.0%Cr, ≤3.0%Mo, 0.08%P, 0.08%S, ≤2.0 %Ni, ≤1.2%Cu.

[0057] C Si mn P S Cr Mo Ni Cu 2.4-3.2 -1.0 0.5-1.5 0.08 0.08 18.0-23.0 -3.0 -2.0 -1.2

Embodiment 2

[0059] When the liner is being processed, the product size chain is first confirmed;

[0060] The second step, the mold model production;

[0061] The third step, mold making;

[0062] The fourth step, modeling;

[0063] The fifth step, paint;

[0064] The sixth step, box distribution;

[0065] The seventh step, dimension inspection;

[0066] The eighth step, close the box;

[0067] The ninth step, ingredients;

[0068] The tenth step, smelting · analysis of chemical composition before furnace · composition adjustment;

[0069] The eleventh step, temperature measurement;

[0070] The twelfth step, pouring;

[0071] The thirteenth step, insulation · unpacking;

[0072] The fourteenth step, semi-finished product inspection and performance test confirmation;

[0073] The fifteenth step, removing the riser (grinding) and heat treatment;

[0074] The sixteenth step, hardness testing;

[0075] The seventeenth step, finished product inspection;

[0076] The eighteenth st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com