Cobalt-free system, positive electrode slurry and homogenizing method and application thereof

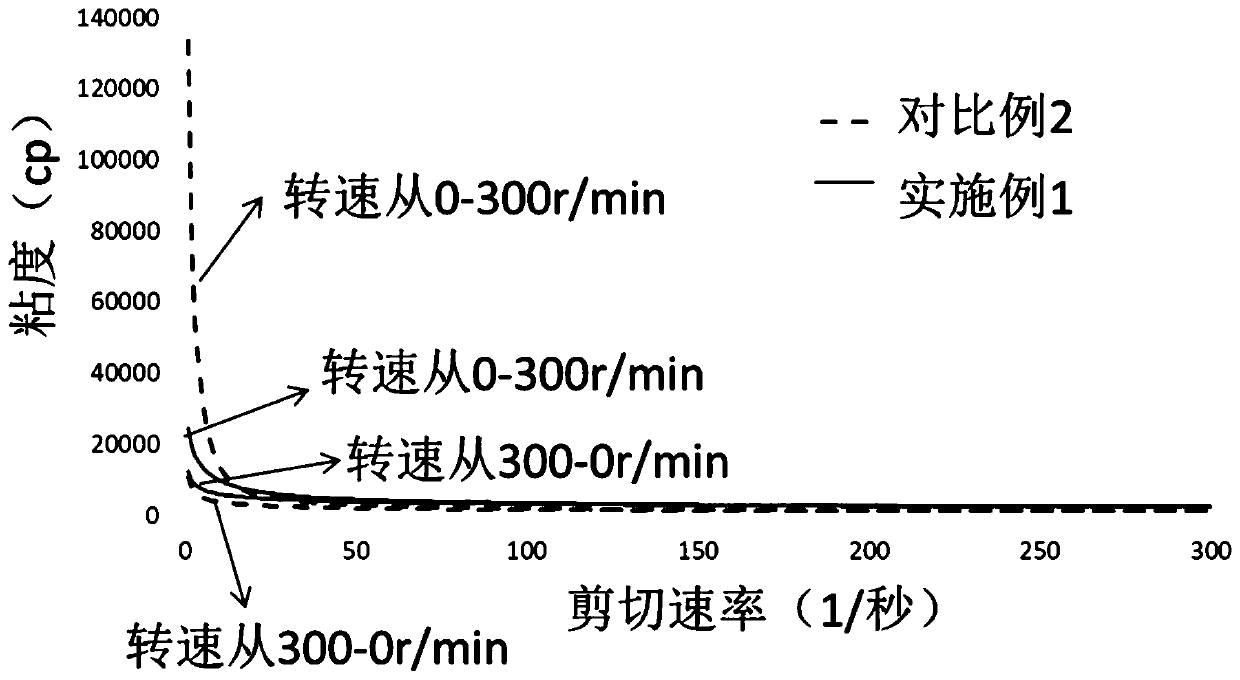

A positive electrode slurry and system technology, applied to battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as easy layering, large viscosity changes, and difficult dispersion of slurry, achieving short swelling time and good dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In a specific embodiment, the chemical formula is Li x Ni y mn z o 2 , wherein x is 1.0-1.1, y is 0.5-0.8, z is the preparation method of the cobalt-free material of 0.2-0.5 comprising the following steps:

[0045] A, the precursor Ni y mn z (OH) 2 , lithium source LiOH and dopant (any one or at least two combinations in Ti, Zr, Al, doping amount is 2000-6000ppm, transition metal=1.04-1.06 in Li / dopant) under stirring condition Mixing is carried out at a mixing speed of 600-1000rpm, and the mixing time is 10-40min to obtain a mixture;

[0046] B. Under the condition of oxygen concentration of 90-100%, the mixture obtained in step A is calcined once. During the first calcining process, the temperature is raised to 930-950 degrees at a heating rate of 1-4 degrees / min, and then kept for 5-15h , to obtain a calcined material;

[0047] C. The primary calcined material obtained in step B is crushed and ground by rollers, and sieved through a 325-mesh sieve to obtain a...

Embodiment 1

[0059] This embodiment provides a cobalt-free system, including 96.5 parts by weight of cobalt-free materials, 1.5 parts by weight of a binder, 1.5 parts by weight of a first conductive agent, 0.5 parts by weight of a second conductive agent, and a pH regulator (added The amount is 0.3% of the dry powder addition amount in the cobalt-free material, binder, first conductive agent and second conductive agent); wherein, the cobalt-free material is LiNi 0.75 mn 0.25 o 2 The binder is polyvinylidene fluoride with a number average molecular weight of 1 million; the conductive agent includes a first conductive agent and a second conductive agent, the first conductive agent is conductive carbon black, and the second conductive agent is a single-walled carbon nanotube; pH The regulator is oxalic acid.

[0060] This embodiment provides a positive electrode slurry, including a glue solution and the above-mentioned cobalt-free system dispersed in the glue solution; the preparation metho...

Embodiment 2

[0070] This embodiment provides a cobalt-free system, including 95.4 parts by weight of cobalt-free materials, 1.8 parts by weight of a binder, 2 parts by weight of a first conductive agent, 0.8 parts by weight of a second conductive agent, and a pH regulator (added The amount is 0.1% of the dry powder addition amount in the cobalt-free material, the binder, the first conductive agent and the second conductive agent); wherein, the cobalt-free material is Li 1.1 Ni 0.8 mn 0.2 o 2 The binder is polyvinylidene fluoride with a number average molecular weight of 500,000; the conductive agent includes a first conductive agent and a second conductive agent, the first conductive agent is conductive carbon black, and the second conductive agent is a single-walled carbon nanotube; pH The regulator is maleic acid.

[0071] This embodiment provides a positive electrode slurry, including a glue solution and the above-mentioned cobalt-free system dispersed in the glue solution; the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com