Neutral cleaning agent for range hood and preparation method thereof

A neutral cleaning agent and range hood technology, which is applied in the preparation of detergent mixture compositions, surface active detergent compositions, detergent compositions, etc., can solve the problems of long effective time and low decontamination efficiency, and achieve Enhanced decontamination ability, long-lasting odor elimination effect, and improved removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

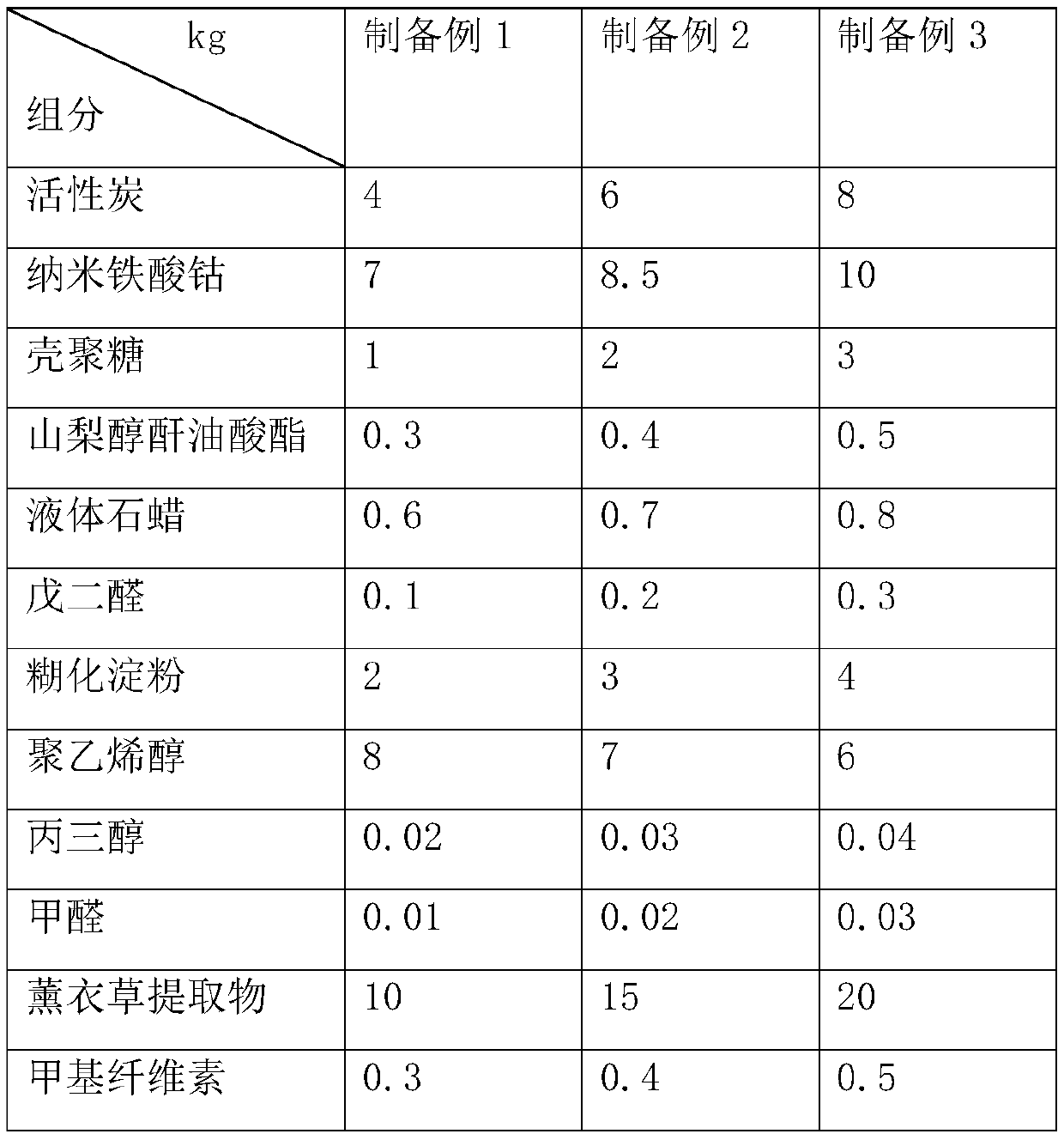

preparation example 1

[0041] Preparation Example 1: (1) According to the raw material ratio in Table 1, soak 4kg of activated carbon in the acetic acid solution of 0.1mol / l for 2h, rinse with distilled water until neutral, filter with suction, and dry to prepare acidified activated carbon, activated carbon The mass ratio to the acetic acid solution is 1:3; (2) Mix 7kg nano-cobalt ferrite and 1kg chitosan, disperse ultrasonically, add 0.3kg sorbitan oleate and 0.6kg liquid paraffin, stir for 30min, add 0.1 kg glutaraldehyde, stirred for 2h, washed successively with petroleum ether, acetone and distilled water, suction filtered, and dried at 60°C to obtain magnetic chitosan microspheres; (3) 2kg gelatinized corn starch and 8kg polyvinyl alcohol were mixed, After stirring for 30 minutes, add 0.02kg of glycerol and 0.01kg of formaldehyde, heat in a water bath to 80°C, and stir for 40 minutes to prepare a slow-release solution. The gelatinized cornstarch is gelatinized at 50°C by cornstarch and water at ...

preparation example 2

[0044] Preparation example 2: (1) according to the ratio of raw materials in Table 1, 6 kg of activated carbon was soaked in the acetic acid solution of 0.1mol / l for 2 hours, rinsed with distilled water until neutral, suction filtered, and dried to obtain acidified activated carbon, activated carbon The mass ratio with the acetic acid solution is 1:4; (2) Mix 8.5kg nano-cobalt ferrite and 2kg chitosan, disperse ultrasonically, add 0.4kg sorbitan oleate and 0.7kg liquid paraffin, stir for 35min, add 0.2kg of glutaraldehyde, stirred for 2.5h, washed successively with petroleum ether, acetone and distilled water, suction filtered, and dried at 60°C to obtain magnetic chitosan microspheres; (3) 3kg of gelatinized cornstarch and 7kg of polyvinyl alcohol Mix, stir for 35 minutes, add 0.03kg of glycerol and 0.02kg of formaldehyde, heat in a water bath to 85°C, and stir for 35 minutes to prepare a slow-release solution. It is prepared by gelatinization for 70 minutes; (4) Mix the sust...

preparation example 3

[0045] Preparation example 3: (1) According to the raw material ratio in Table 1, soak 8kg gac in the acetic acid solution of 0.1mol / l concentration for 2h, rinse with distilled water until neutral, suction filter, dry, and make acidified gac, gac The mass ratio to the acetic acid solution is 1:5; (2) Mix 10kg nano-cobalt ferrite and 3kg chitosan, disperse ultrasonically, add 0.5kg sorbitan oleate and 0.8kg liquid paraffin, stir for 40min, add 0.3 kg glutaraldehyde, stirred for 3h, washed successively with petroleum ether, acetone and distilled water, suction filtered, and dried at 60°C to obtain magnetic chitosan microspheres; (3) 4kg gelatinized corn starch and 6kg polyvinyl alcohol were mixed, After stirring for 40 minutes, add 0.04kg of glycerin and 0.03kg of formaldehyde, heat in a water bath to 90°C, and stir for 30 minutes to prepare a slow-release solution. The gelatinized cornstarch is gelatinized at 90°C by cornstarch and water at a mass ratio of 20:1 Prepared in 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com