Low-stress epoxy resin intumescent fireproof coating material

A technology of epoxy resin and fireproof coating, which is applied in the field of refractory materials, can solve the problems of new lightweight composite materials such as deformation, insufficient flexibility, and large internal stress of the coating, so as to improve the flame retardant effect, enhance the adhesion, and improve the coating quality. Effect of Layer Bond Strength and Shrinkage Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

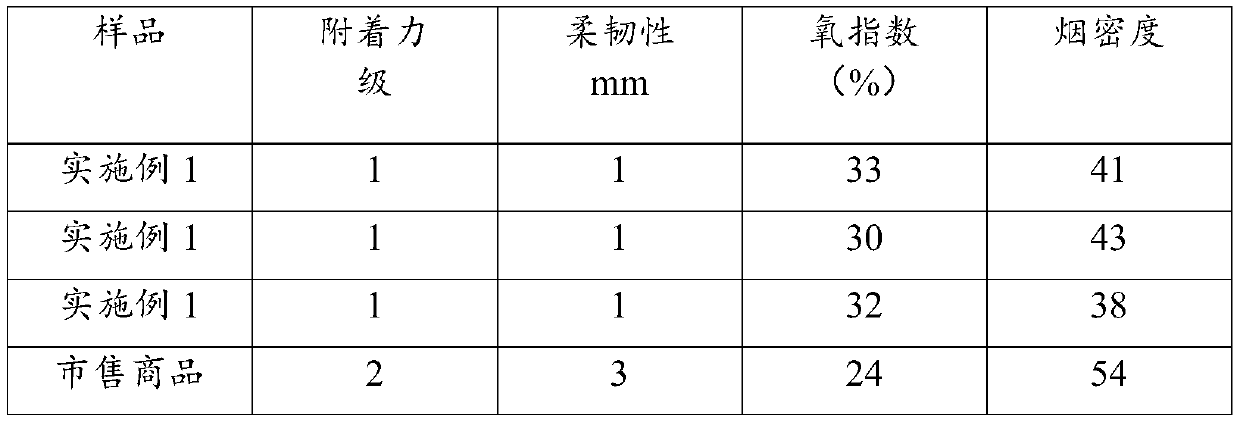

Examples

Embodiment 1

[0028] This embodiment provides a low-stress epoxy resin expansion type fireproof coating material. The coating material includes two components, A and B, in parts by weight, and the specific composition is as follows:

[0029] Component A: 36 parts of modified epoxy resin, 5 parts of 1-butyl-3-methyltetrafluoroborate, 8 parts of char-forming agent, 7 parts of trimethyl phosphate, 3 parts of melamine phosphate, butanediol 9 parts of alcohol diglycidyl ether;

[0030] The modified epoxy resin is the E-44 epoxy resin modified by phenyltrimethoxysilane; the modification method of the epoxy resin: mix phenyltrimethoxysiloxane and E-44 epoxy resin According to the mass ratio of 1:12, mix well and react at 70-80°C for 4-5h;

[0031] The char-forming agent is a mixture of sulfur-free expandable graphite and graphene oxide, and the mass ratio of the two is 1:0.02; the sulfur-free expandable graphite is a mixed acid system of perchloric acid-phosphoric acid-acetic anhydride, with perm...

Embodiment 2

[0040] This embodiment provides a low-stress epoxy resin expansion type fireproof coating material. The coating material includes two components, A and B, in parts by weight, and the specific composition is as follows:

[0041] Component A: 40 parts of modified epoxy resin, 5 parts of 1-butyl-3-methyltetrafluoroborate, 10 parts of char-forming agent, 7 parts of triisopropylphenyl phosphate, 5 parts of melamine pyrophosphate part, 10 parts of glycerol epoxy resin;

[0042] Described modified epoxy resin and preparation method are with embodiment 1;

[0043] The char-forming agent is a mixture of sulfur-free expandable graphite and graphene oxide, and the mass ratio of the two is 1:0.03; the preparation method is the same as in Example 1.

[0044] Component B: 40 parts of ethylenediamine curing agent, 14 parts of amino-terminated polysulfide rubber, 43 parts of pigment and filler, 30 parts of glass fiber, and 6 parts of tert-butanol;

[0045] Described amino-terminated polysulfi...

Embodiment 3

[0050] This embodiment provides a low-stress epoxy resin expansion type fireproof coating material. The coating material includes two components, A and B, in parts by weight, and the specific composition is as follows:

[0051] Component A: 48 parts of modified epoxy resin, 12 parts of 1-butyl-3-methyltetrafluoroborate, 13 parts of char-forming agent, 9 parts of triethyl phosphate, 6 parts of melamine, n-butyl shrink 13 parts of glycerol ether;

[0052] Described modified epoxy resin and preparation method are with embodiment 1;

[0053] The char-forming agent is a mixture of sulfur-free expandable graphite and graphene oxide, and the mass ratio of the two is 1:0.02; the preparation method is the same as in Example 1.

[0054] Component B: 43 parts of ethylenediamine curing agent, 20 parts of amino-terminated polysulfide rubber, 48 parts of pigment and filler, 30 parts of rock wool, and 8 parts of tert-butanol;

[0055] Described amino-terminated polysulfide rubber and prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com