Preparation method of environment-friendly foamed styrene-butadiene rubber

A styrene-butadiene rubber, environmentally friendly technology, applied in the field of preparation of environmentally friendly foamed styrene-butadiene rubber, can solve the problems of many types of raw materials, difficult component distribution, and affecting the performance of foamed materials, so as to inhibit interaction and improve Mechanical loss performance, the effect of improving the flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of environment-friendly foamed styrene-butadiene rubber. The foamed styrene-butadiene rubber is made of the following raw materials in parts by weight: 90-100 parts of modified styrene-butadiene rubber, 16-20 parts of natural rubber, 45-50 parts of white carbon black 1.6-2 parts of zinc oxide, 3-4 parts of accelerator, 1.8-2 parts of sulfur, 2.7-3 parts of foaming agent;

[0026] Among them, the accelerator is the accelerator TMTD; the foaming agent is OBSH-75;

[0027] The flame retardant was prepared as follows:

[0028] (1) Diethyl chlorophosphate is dissolved in acetonitrile to form a phosphorus-containing solution with a concentration of 0.8mol / L;

[0029] (2) Dissolve 2.0g of 2,4-diaminotoluene and 3.3g of triethylamine in 180-200mL of acetonitrile, stir and mix evenly, pass nitrogen gas for 15min and control the solution temperature at 3-4°C. Slowly drop 38-40mL of phosphorus-containing solution into the mixture under nitrogen, keep the ice...

Embodiment 1

[0041] An environmentally friendly foamed styrene-butadiene rubber is made of the following raw materials in parts by weight: 90 parts of modified styrene-butadiene rubber, 16 parts of natural rubber, 45 parts of white carbon black, 1.6 parts of zinc oxide, 3 parts of accelerator, 1.8 parts of sulfur, 2.7 parts of blowing agent;

[0042] The rubber is made by the following steps:

[0043] The first step is to turn on the internal mixer and set the temperature to 100°C. When the temperature of the instrument reaches the temperature, add the modified styrene-butadiene rubber and natural rubber to the internal mixer for 13 minutes, and then add white carbon black and zinc oxide Banburying for 5 minutes, then adding foaming agent, sulfur and accelerator to continue banburying for 5 minutes to obtain a blended rubber;

[0044] In the second step, after the blended rubber is parked at room temperature for 24 hours, set the temperature of the mill to 80°C, and carry out milling of t...

Embodiment 2

[0047] An environmentally friendly foamed styrene-butadiene rubber is made of the following raw materials in parts by weight: 95 parts of modified styrene-butadiene rubber, 18 parts of natural rubber, 48 parts of white carbon black, 1.82 parts of zinc oxide, 3.5 parts of accelerator, 1.9 parts of sulfur, 2.8 parts of blowing agent;

[0048] The rubber is made by the following steps:

[0049] The first step is to turn on the internal mixer and set the temperature to 100°C. When the temperature of the instrument reaches the temperature, add the modified styrene-butadiene rubber and natural rubber to the internal mixer for 14 minutes, and then add white carbon black and zinc oxide. Banburying for 5.5 minutes, then adding foaming agent, sulfur and accelerator to continue banburying for 5.5 minutes to obtain a blended rubber;

[0050] In the second step, after the blended rubber is parked at room temperature for 24 hours, set the temperature of the mill to 80°C, and carry out mill...

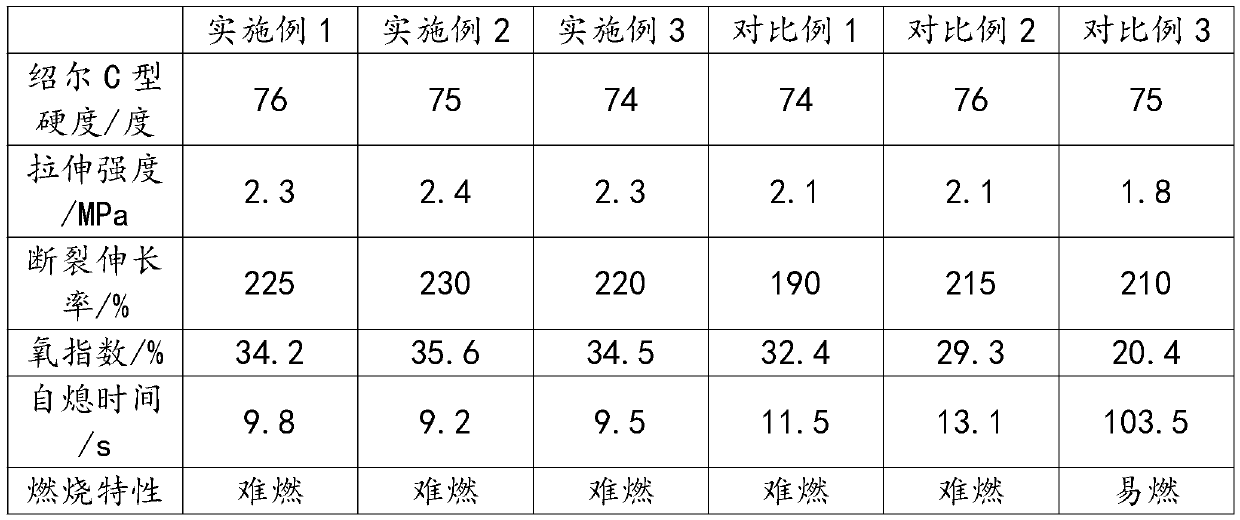

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com