Antibacterial carved stone ceramic tile and preparation method thereof

A technology of stone tiles and fine carving, which is applied in the field of antibacterial fine carving stone tiles and its preparation, can solve the problems that the antibacterial function of antibacterial tiles is difficult to maintain for a long time, the bonding force between the antibacterial layer and the glaze surface is weak, and the antibacterial performance is unstable. Air purification effect, improvement of photocatalytic activity, and effect of reducing recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

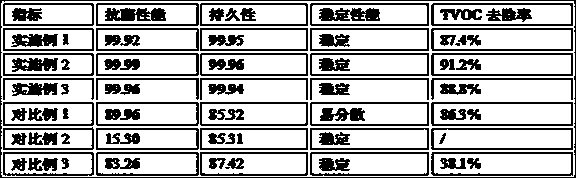

Examples

Embodiment 1

[0042] An antibacterial finely carved stone tile, which is made of the following raw materials through ball milling, molding, one-time sintering, inkjet, glazing with the addition of a composite photocatalytic antibacterial agent, secondary sintering, and polishing and trimming. The parts mentioned are all by weight share:

[0043] Kaolin 5 parts;

[0044] 5 parts of ball soil;

[0045] Potassium feldspar 25 parts;

[0046] 25 parts of china clay;

[0047] 5 parts pyrophyllite;

[0048] Covering glaze 2 parts;

[0049] TiO 2 / Ag 2 2 parts of O composite microspheres;

[0050] 2 to 5 parts of bentonite.

[0051] The glaze includes the following raw materials in parts by weight: 25 parts of albite, 13 parts of kaolin, 8 parts of dolomite, 2 parts of aluminum oxide, 5 parts of zinc oxide, and 6 parts of burnt talc.

[0052] Wherein said kaolin is preferably Suzhou Yangshan kaolin, Al 2 o 3 The content is 35-45%, and the color is white; the ball clay mentioned here is pre...

Embodiment 2

[0063] An antibacterial finely carved stone tile, which is made of the following raw materials through ball milling, molding, one-time sintering, inkjet, glazing with the addition of a composite photocatalytic antibacterial agent, secondary sintering, and polishing and trimming. The parts mentioned are all by weight share:

[0064] Kaolin 20 parts;

[0065] 16 parts of ball soil;

[0066] Potassium feldspar 45 parts;

[0067] 36 parts of china clay;

[0068] 8 parts pyrophyllite;

[0069] Covering glaze 6 parts;

[0070] TiO 2 / Ag 2 6 parts of O composite microspheres;

[0071] Bentonite 3 parts.

[0072] The glaze includes the following raw materials in parts by weight: 26 parts of albite, 14 parts of kaolin, 11 parts of dolomite, 5 parts of aluminum oxide, 7 parts of zinc oxide, and 8 parts of burnt talc.

[0073] Wherein said kaolin is preferably Suzhou Yangshan kaolin, Al 2 o 3 The content is 35-45%, and the color is white; the ball clay mentioned here is prefer...

Embodiment 3

[0076] An antibacterial finely carved stone tile, which is made of the following raw materials through ball milling, molding, one-time sintering, inkjet, glazing with the addition of a composite photocatalytic antibacterial agent, secondary sintering, and polishing and trimming. The parts mentioned are all by weight share:

[0077] Kaolin 25 parts;

[0078] 26 parts of ball soil;

[0079] Potassium feldspar 50 parts;

[0080] 40 parts of china clay;

[0081] 10 parts pyrophyllite;

[0082] Covering glaze 10 parts;

[0083] TiO 2 / Ag 2 10 parts of O composite microspheres;

[0084] Bentonite 5 parts.

[0085] The glaze includes the following raw materials in parts by weight: 30 parts of albite, 15 parts of kaolin, 15 parts of dolomite, 8 parts of aluminum oxide, 10 parts of zinc oxide, and 10 parts of burnt talc.

[0086] Wherein said kaolin is preferably Suzhou Yangshan kaolin, Al 2 o 3 The content is 35-45%, and the color is white; the ball clay mentioned here is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com