Oxygen-doped porous g-C3N4 photocatalyst, preparation method thereof and application of the photocatalyst

A photocatalyst, g-c3n4 technology, applied in the field of photocatalytic materials, can solve the problems of seldom processing precursor element doping, low photocatalytic activity, easy recombination of photogenerated electrons, etc., to achieve easy and effective separation and increase specific surface area. , the effect of promoting electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Pure g-C 3 N 4 (CNO) photocatalyst

[0032] (1) Preparation method

[0033] Calcinate 2.52g of melamine directly at 550°C for 2-4h under nitrogen atmosphere, and the heating rate is 5°C / min to obtain pure g-C 3 N 4 (CNO) photocatalyst.

[0034] (2) Detection

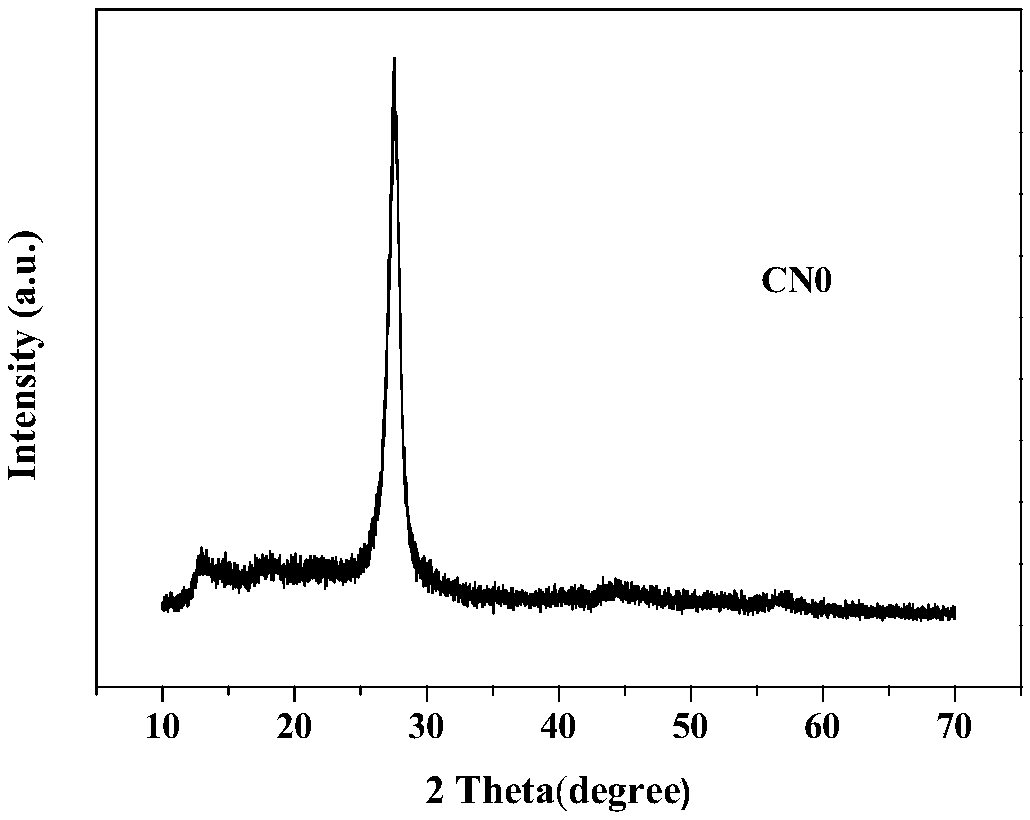

[0035] figure 1 is the XRD test chart of sample CN0, by figure 1 It can be seen that the sample has two diffraction peaks at 13° and 27°.

[0036] figure 2 is the SEM image of sample CN0, by figure 2 Visible, pure g-C 3 N 4 The particles are relatively large, all reunited together.

Embodiment 2

[0037] Example 2 Oxygen-doped porous g-C 3 N 4 catalyst of light

[0038] (1) Preparation method

[0039] 1) Add 2.52 g of melamine into 100 mL of deionized water, heat in a water bath at 80° C. and magnetically stir for 30 minutes until dissolved to obtain a melamine solution. Under the condition of heating and stirring at 80°C, add 4.59 μL formaldehyde dropwise to the melamine solution, heat and continue to stir for 2 hours, put the resulting mixture in an oven, and dry it at 120°C for 24 hours to obtain a solid, which is the precursor;

[0040] 2) Grind the precursor in a mortar, put it into an alumina crucible, and calcinate it in a tube furnace at 550°C for 4 hours in a nitrogen atmosphere to obtain the intermediate product GN1;

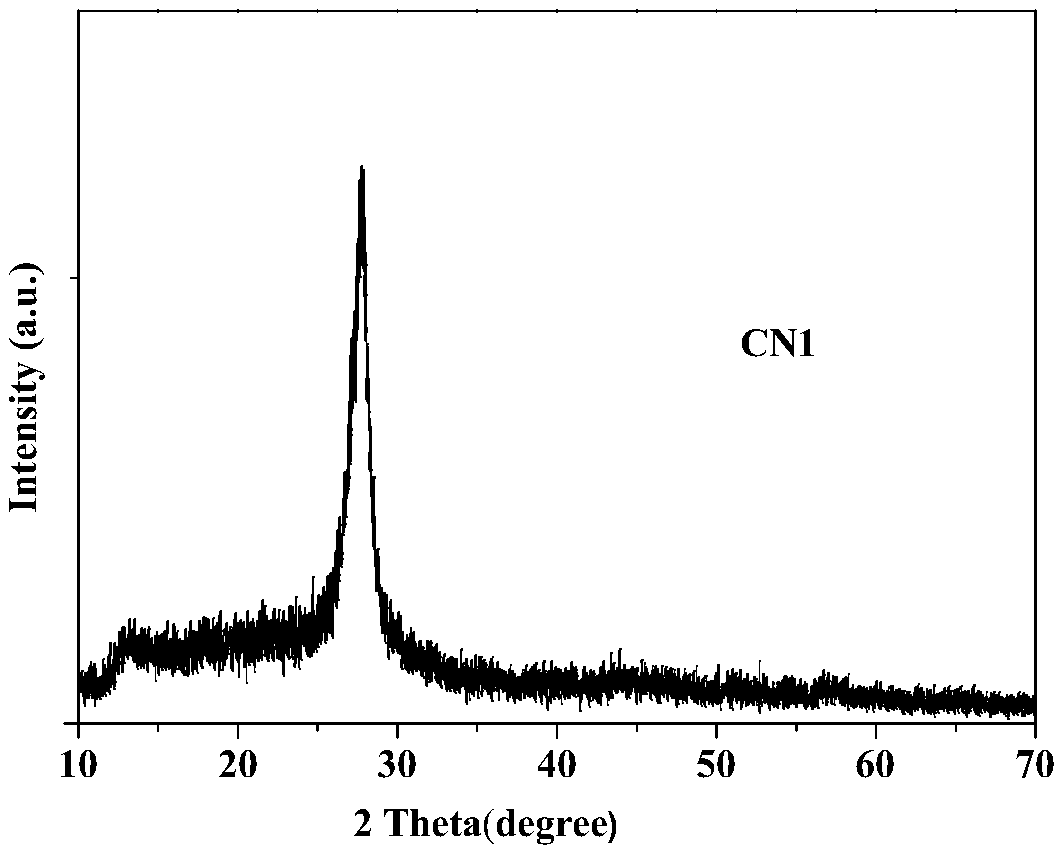

[0041] 3) The intermediate product GN1 was calcined in a muffle furnace at 550°C for 4 hours in an air environment to remove the carbon residue of formaldehyde and obtain the target product—oxygen-doped porous g-C 3 N 4 Photocatalyst (CN1)....

Embodiment 3

[0046] Example 3 Oxygen-doped porous g-C 3 N 4 composite photocatalyst

[0047] (1) Preparation method

[0048] 1) Add 2.52 g of melamine into 100 mL of deionized water, heat it in a water bath at 60° C. and stir it magnetically for 30 minutes until it dissolves to obtain a melamine solution. Under heating and stirring at 60°C, add 11.46 μL of formaldehyde dropwise to the melamine solution, heat and continue to stir for 2 hours, put the resulting mixture in an oven, and dry it at 100°C for 24 hours to obtain a solid, which is the precursor;

[0049] 2) Grind the precursor in a mortar, put it into an alumina crucible, and calcinate it in a tube furnace at 550°C for 3 hours in a nitrogen atmosphere to obtain the intermediate product GN2;

[0050] 3) The intermediate product GN2 was calcined in a muffle furnace at 550°C for 3 hours in an air environment to remove the carbon residue of formaldehyde, and the target product was oxygen-doped porous g-C 3 N 4 Photocatalyst (CN2)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com