Preparation method for modifying nanofiltration membrane by utilizing carboxylated nanocellulose crystals

A nanocellulose, carboxylation technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of insufficient hydrophilicity of additives, human and environmental hazards, and toxic additives, and achieve good anti-pollution characteristics, Environmentally friendly, highly selective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: The carboxylated nanocellulose crystals used in this implementation are completed according to the following steps:

[0037] Step 1. Mix 500 mg of nanocellulose crystals with 50 mL of deionized water to obtain a suspension of nanocellulose crystals, then add 0.01 g of tetramethylpiperidine nitrogen oxide (TEMPO) and 0.21 g of sodium bromide;

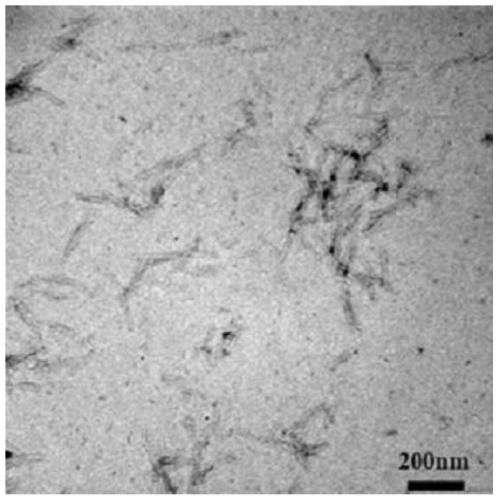

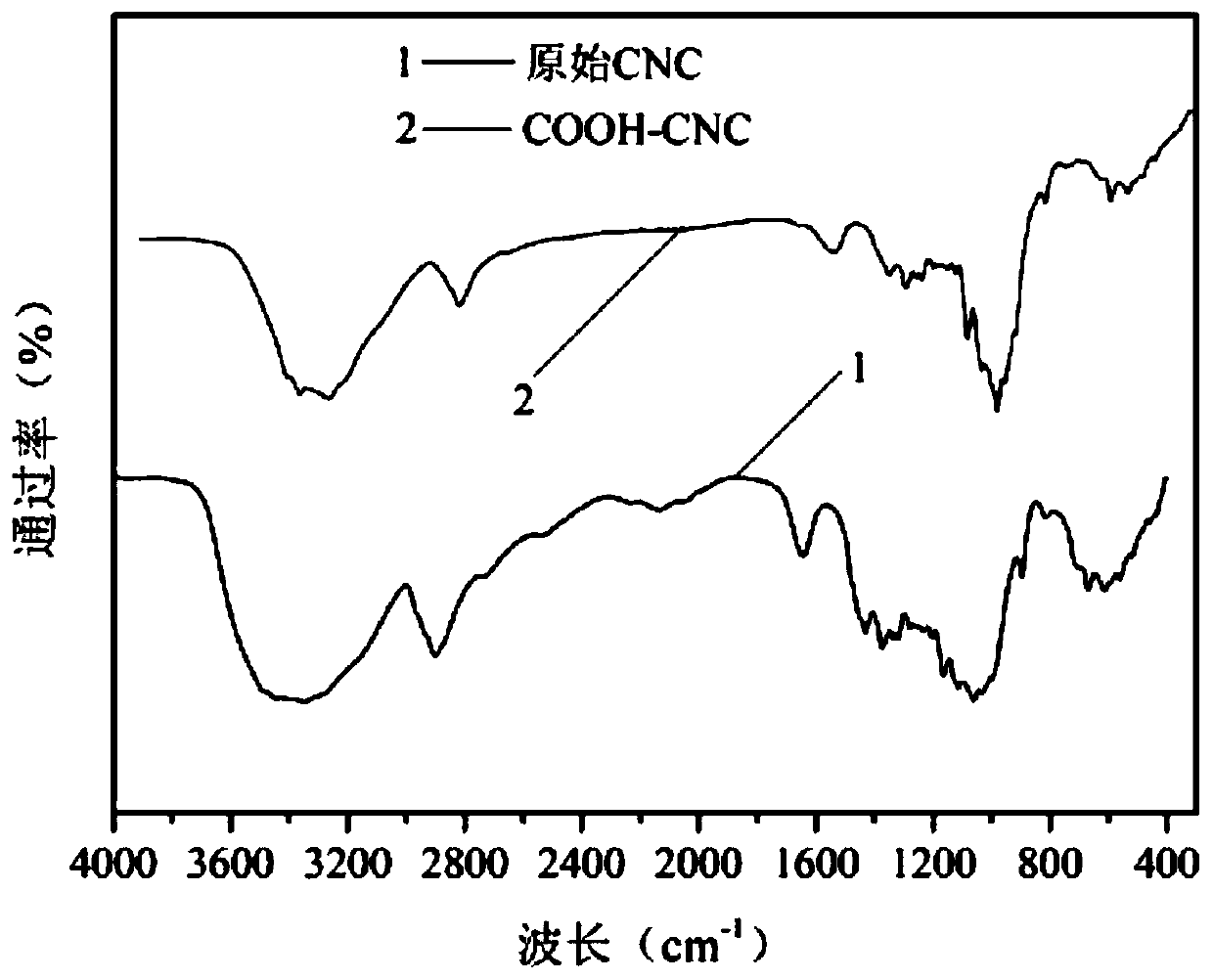

[0038] Step 2, then stir at 200rpm for 5min, then use a sodium hypochlorite solution with a concentration of 1.24mol / L, adjust the pH value to 10 with hydrochloric acid, carry out the oxidation reaction for 45min under continuous stirring, terminate the oxidation reaction with methanol, and then add hydrochloric acid to adjust the pH value When the pH value is equal to 7, dialyze the water-insoluble substance for one week to remove impurities, and then freeze-dry to obtain carboxylated nanocellulose crystals. The diameter of the obtained carboxylated nanocellulose crystals is 15-30nm, and the length is 50-150nm. Rod-...

Embodiment 2

[0050] Example 2: The carboxylated nanocellulose crystals used in this implementation were prepared by the method in Example 1.

[0051] Utilize the preparation method of carboxylated nano-cellulose crystal modified nanofiltration membrane in this implementation to carry out according to the following steps:

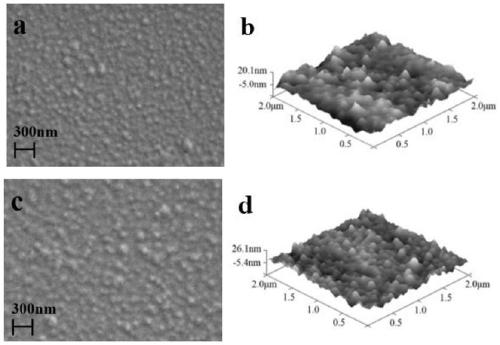

[0052] Step 1. Add carboxylated nanocellulose crystals to 20 mL of a piperazine solution with a concentration of 0.5 wt%, and ultrasonically disperse until uniformly dispersed to obtain an aqueous solution of carboxylated nanocellulose crystals with a concentration of 0.02 wt% piperazine;

[0053] Step 2, using concentration as 0.15wt% Na 3 PO 4 12H 2 O solution adjusts the pH value of the piperazine aqueous phase solution obtained in step 1 to 11;

[0054] Step 3, immersing the polyethersulfone membrane in the piperazine aqueous phase solution treated in step 2, taking it out after immersing for 20 minutes, and then removing the excess solution on the surface;

[00...

Embodiment 3

[0057] Example 3: The carboxylated nanocellulose crystals used in this implementation were prepared by the method in Example 1.

[0058] Utilize the preparation method of carboxylated nano-cellulose crystal modified nanofiltration membrane in this implementation to carry out according to the following steps:

[0059] Step 1. Add carboxylated nanocellulose crystals to 20 mL of a piperazine solution with a concentration of 1.20 wt%, and ultrasonically disperse until uniformly dispersed to obtain an aqueous solution of carboxylated nanocellulose crystals with a concentration of 0.01 wt% piperazine;

[0060] Step 2, use concentration as 0.2wt% Na 3 PO 4 12H 2 O solution adjusts the pH value of the piperazine aqueous phase solution obtained in step 1 to 11;

[0061] Step 3, immersing the polyethersulfone membrane in the piperazine aqueous phase solution treated in step 2, taking it out after immersing for 15 minutes, and then removing the excess solution on the surface;

[0062...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com