High-performance ablation-resistant coating and preparation method thereof

An ablation-resistant, high-performance technology, applied in the direction of fire-proof coatings, epoxy resin coatings, polycarbonate coatings, etc., can solve the problems of high-temperature damage and easy peeling of internal equipment that cannot protect the grassroots, so as to improve repairability and solve The effect of excessive specific gravity, excellent ablation resistance and heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

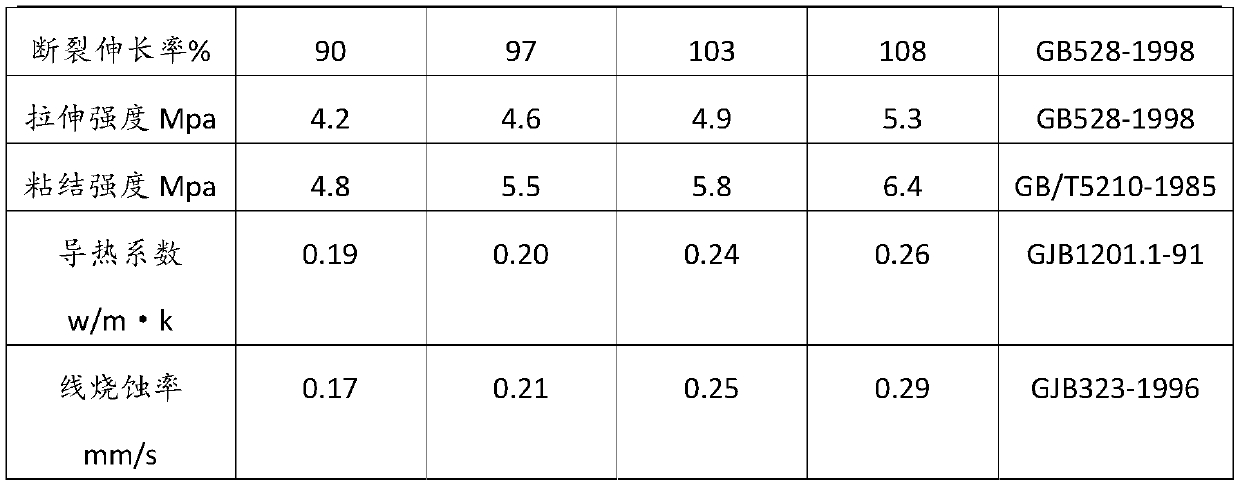

Examples

Embodiment 1

[0045]With 60 parts by weight of methyl phenyl polysiloxane resin, 10 parts by weight of polyethylene glycol 6000, 1 part by weight of hexamethylene diisocyanate (HDI), 30 parts by weight of hollow glass microspheres, 15 parts by weight of cellulose acetate , 1 part by weight of nano-scale amorphous carbon black, 1 part by weight of simethicone, 1 part by weight of KH-550, 20 parts by weight of ethyl acetate, stirred at a constant speed of 3000r / min for 1 hour, and prepared heat-insulating coating A group point. Then 3 parts by weight of ethyl orthosilicate, 0.5 parts by weight of dibutyltin dilaurate, and 15 parts by weight of ethyl acetate were stirred at a constant speed of 1000r / min for 0.5 hours to prepare component B of the heat-insulating coating. Component A and heat insulation B component are fully stirred and evenly applied to the surface of the substrate by spraying or brushing, and dried at room temperature for 48 hours to obtain a heat insulation layer.

[0046] ...

Embodiment 2

[0048] With 64 parts by weight of methyl phenyl polysiloxane resin, 13 parts by weight of polyglycerol 4000, 1.4 parts by weight of HDI, 36 parts by weight of nano-ceramic hollow microspheres, 19 parts by weight of cellulose acetate, 1.3 parts by weight of nano-scale amorphous Carbon black, 1.3 parts by weight of simethicone oil, 1.3 parts by weight of KH-550, and 40 parts by weight of butyl acetate were stirred at a constant speed of 4000r / min for 1 hour to prepare component A of the thermal insulation coating. Then 4 parts by weight of tetraethyl orthosilicate, 0.7 parts by weight of dibutyltin dilaurate, and 20 parts by weight of butyl acetate were stirred at a constant speed of 2000r / min for 0.5 hours to prepare component B of the heat-insulating coating. Component A and heat insulation B component are fully stirred and evenly applied to the surface of the substrate by spraying or brushing, and dried at room temperature for 48 hours to obtain a heat insulation layer.

[00...

Embodiment 3

[0051] 68 parts by weight of methyl phenyl polysiloxane resin, 18 parts by weight of polypentaerythritol 4000, 1.8 parts by weight of isophorone diisocyanate (IPDI), 42 parts by weight of silica airgel, 25 parts by weight of hydroxyethyl Cellulose, 1.8 parts by weight of nano-scale amorphous carbon black, 1.8 parts by weight of simethicone, 1.8 parts by weight of KH-560, 50 parts by weight of methyl ethyl ketone and acetone mixed solution, stirred at a constant speed of 4000r / min for 2 hours, obtained Thermal insulation coating A component. Then 4 parts by weight of tetraethyl orthosilicate, 0.7 parts by weight of stannous octoate, 23 parts by weight of methyl ethyl ketone and acetone mixed solution were stirred at a constant speed of 2000r / min for 1 hour to prepare component B of the heat-insulating coating, and then The thermal component A and the thermal insulation component B are fully stirred and evenly coated on the surface of the substrate by spraying or brushing, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com