Phenyl organic acid compound modified graphite negative electrode material and preparation method thereof

A negative electrode material, graphite negative electrode technology, applied in negative electrodes, active material electrodes, battery electrodes, etc., can solve problems such as inability to use water-based binders, high brittleness of inorganic oxides, and increased internal resistance, and improve long-term cycle stability. Effects of performance and high temperature cycling stability, Li-ion mobility enhancement, and rate capability enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of negative electrode material, comprising the following steps:

[0040] (a) heat treatment after mixing pre-oxidized graphite, phenyl organic acid compound and organic solvent to obtain a composite material;

[0041] (b) performing vacuum heat treatment on the composite material to obtain the negative electrode material.

[0042] The graphite in the present invention is preferably spherical graphite.

[0043] The pre-oxidation temperature in the present invention is preferably 200-500°C, more preferably 250-450°C, further preferably 300-400°C; the pre-oxidation time is preferably 2-3 hours, more preferably 2.5 hours.

[0044] The pre-oxidation process of the present invention does not require high-temperature treatment, has low energy consumption, is environmentally friendly, and is easy to realize large-scale preparation of high-performance graphite, and has important development and application prospects.

[00...

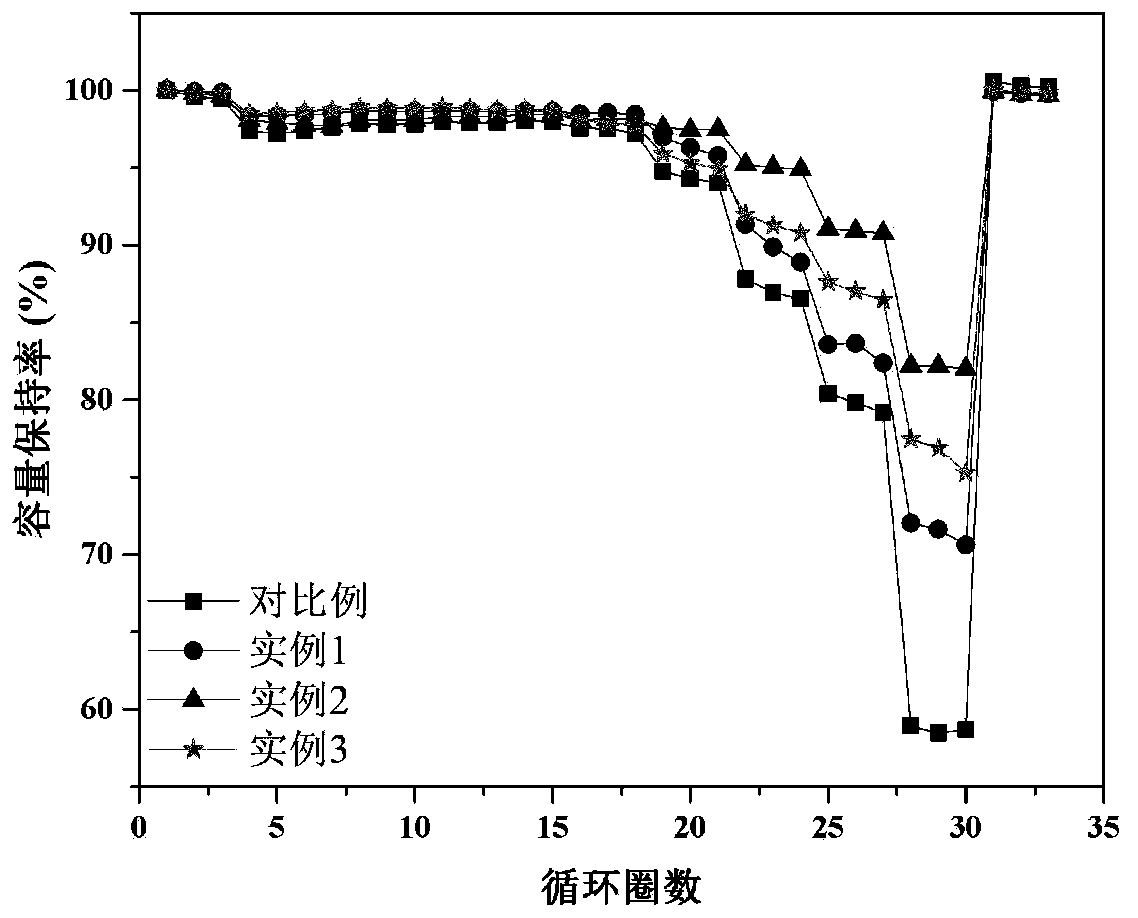

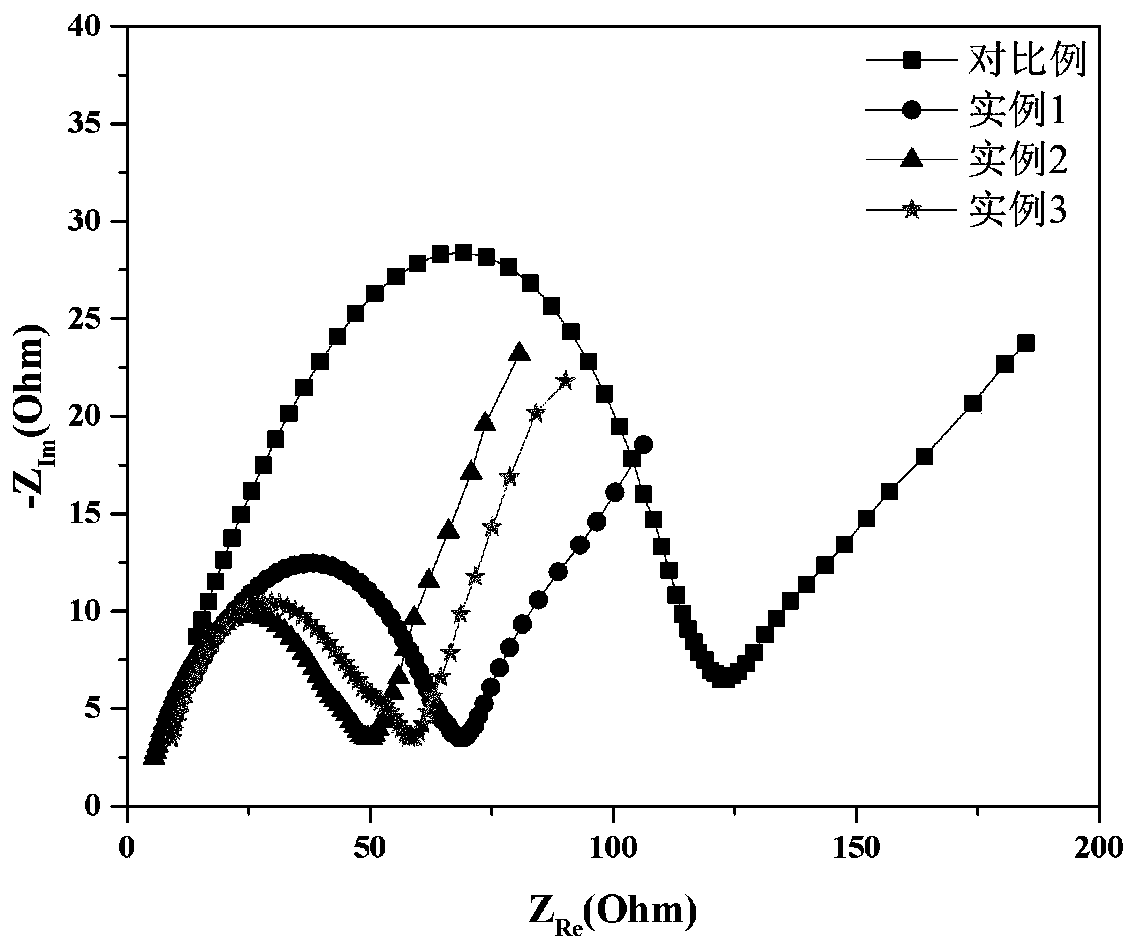

Embodiment 1

[0055] Put 200g of spherical natural graphite in an air environment at 400°C and pre-oxidize for 3 hours; dissolve 4g of trifluoromethylbenzenesulfonic acid in 100mL of NMP solvent, stir well to form a uniform organic solution, and then mix it with the pre-oxidized graphite. Heating to 120°C under constant stirring for 3 hours to completely volatilize the solvent to obtain a composite material; heat-treat the obtained composite material at 120°C for 4 hours under a vacuum of -0.09MPa to obtain trifluoroform Benzenesulfonic acid modified graphite anode material. Fully disperse the obtained graphite negative electrode material with 1g of conductive carbon black, 2g of sodium carboxymethylcellulose binder, and 1g of styrene-butadiene rubber binder in deionized water, dry at 60°C for 1 hour after coating, and obtain The graphite negative electrode sheet was sliced, then vacuum-dried at 120°C for 12 hours, and assembled into a C2032 button cell in a glove box.

[0056] Electrochem...

Embodiment 2

[0058] This example is basically the same as Example 1, except that 4g of terephthalic acid is dissolved in 100mL of ethanol solvent to prepare an organic solution, mixed with pre-oxidized graphite, and heated to Heating at 60°C for 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com