A kind of high-efficiency hydrogen sulfide selective oxidation catalyst and preparation method thereof

A catalyst and selective technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of easy "poisoning, complicated preparation process, low utilization rate, etc., and achieve high desulfurization efficiency and simple synthesis , high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The invention provides a preparation method of an efficient hydrogen sulfide selective oxidation catalyst, which specifically comprises the following steps:

[0029] 1) Weigh a certain mass of carbon nitride precursor and place it in an alumina crucible, place the crucible in a muffle furnace, and set a heating program, at a heating rate of 10 ℃ / min, raise it to 550 ℃ and keep it for 30 minutes, wait for The temperature of the furnace is naturally lowered to room temperature, and the graphite phase carbon nitride (yellow solid) is taken out;

[0030] 2) Weigh 100mg ferric nitrate, 300mg glucose and 100mg graphitic carbon nitride obtained in 1), and the three are mixed and ground for 30min to obtain mixed powder;

[0031] 3) Put the mixed powder in 2) in a tube furnace, extract the vacuum, and then feed nitrogen, repeat this operation three times, set a temperature rise program, raise the temperature to 600°C at a heating rate of 10°C / min, and keep the temperature for 30...

Embodiment 2

[0035] 1) Weigh a certain mass of carbon nitride precursor and place it in an alumina crucible, place the crucible in a muffle furnace, and set a heating program, at a heating rate of 10 ℃ / min, raise it to 550 ℃ and keep it for 30 minutes, wait for The temperature of the furnace is naturally lowered to room temperature, and the graphite phase carbon nitride (yellow solid) is taken out;

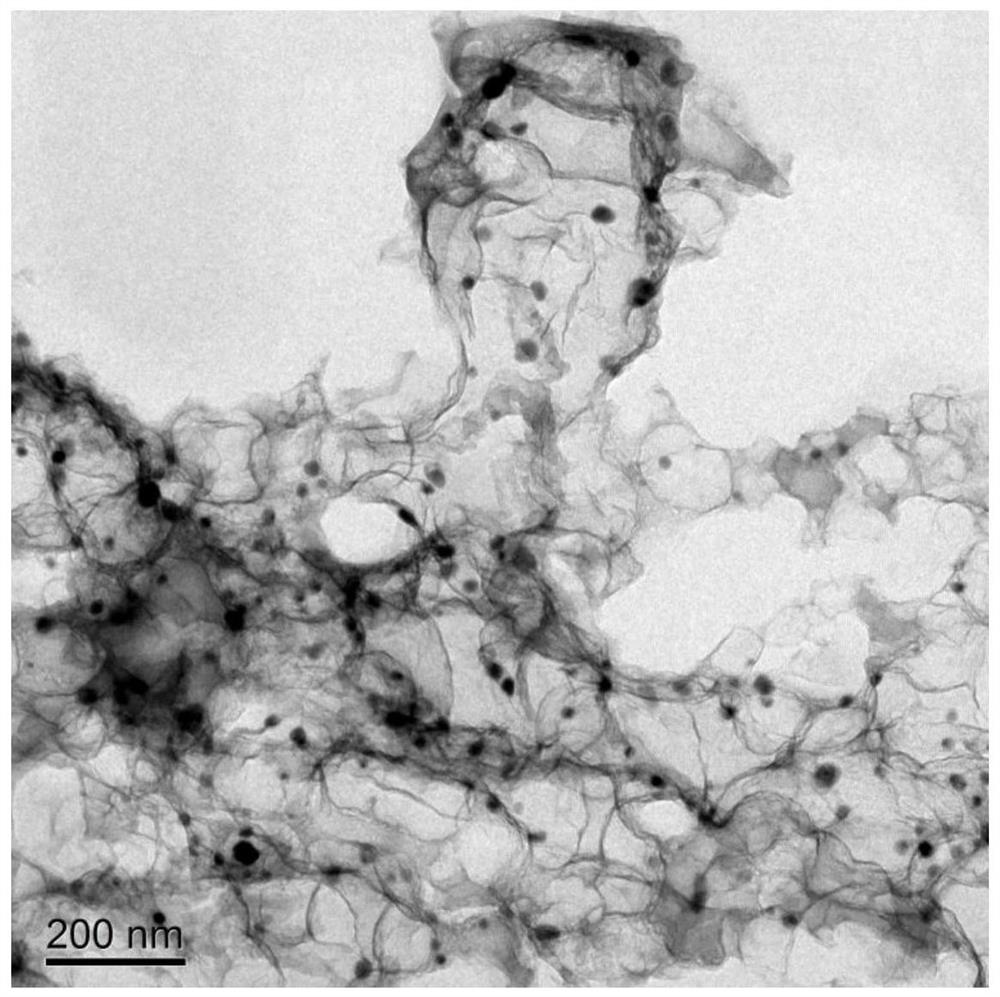

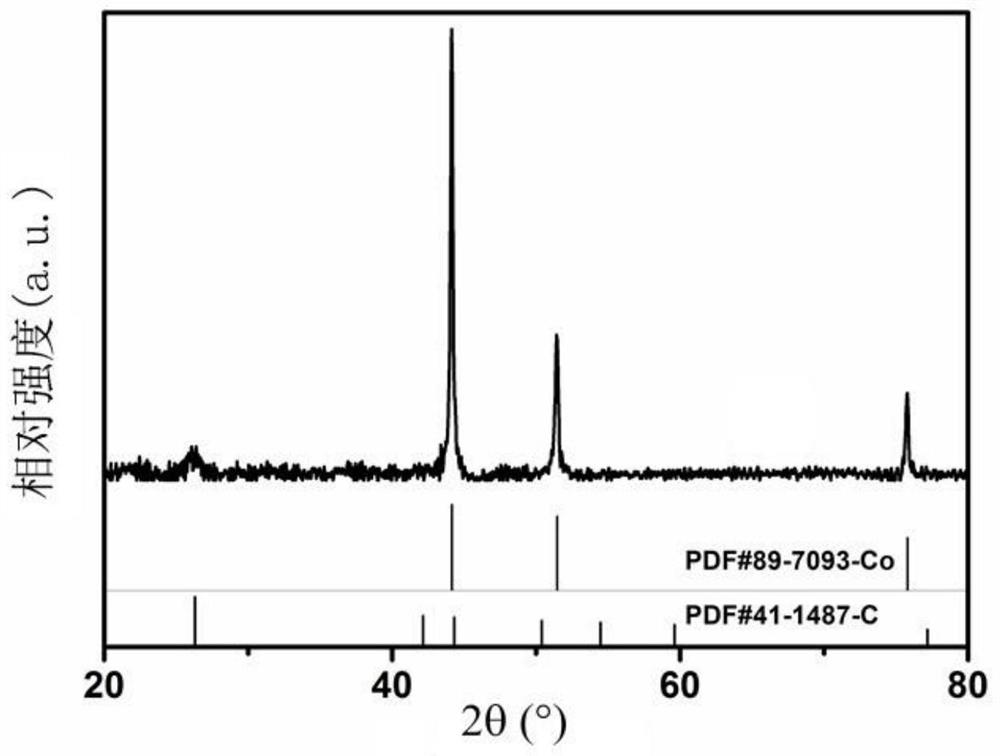

[0036] 2) Weigh 200mg of cobalt nitrate, 300mg of glucose and 100mg of the graphitic carbon nitride obtained in 1), and the three are mixed and ground for 30min to obtain mixed powder;

[0037] 3) Put the mixed powder in 2) in a tube furnace, extract the vacuum, and then feed nitrogen, repeat this operation three times, set a temperature rise program, raise the temperature to 600°C at a heating rate of 10°C / min, and keep the temperature for 30min. The temperature was lowered to room temperature, and the product was ground to prepare a carbon-coated cobalt nanoparticle catalyst.

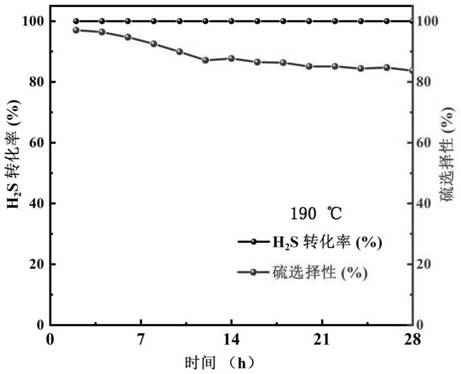

[0038] In a ...

Embodiment 3

[0041] 1) Weigh a certain mass of carbon nitride precursor and place it in an alumina crucible, place the crucible in a muffle furnace, and set a heating program, at a heating rate of 10 ℃ / min, raise it to 550 ℃ and keep it for 30 minutes, wait for The temperature of the furnace is naturally lowered to room temperature, and the graphite phase carbon nitride (yellow solid) is taken out;

[0042] 2) Weigh 500mg of cobalt nitrate, 300mg of glucose and 100mg of the graphitic carbon nitride obtained in 1), and the three are mixed and ground for 30min to obtain mixed powder;

[0043] 3) Put the mixed powder in 2) in a tube furnace, extract the vacuum, and then feed nitrogen, repeat this operation three times, set a temperature rise program, raise the temperature to 600°C at a heating rate of 10°C / min, and keep the temperature for 30min. The temperature was lowered to room temperature, and the product was ground to prepare a carbon-coated cobalt nanoparticle catalyst.

[0044] In a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com