Composite material with high dielectric constant and preparation method thereof

A high dielectric constant, composite material technology, applied in the field of materials, can solve the problems of expensive, complicated preparation process, etc., and achieve the effect of low cost, large dielectric constant, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

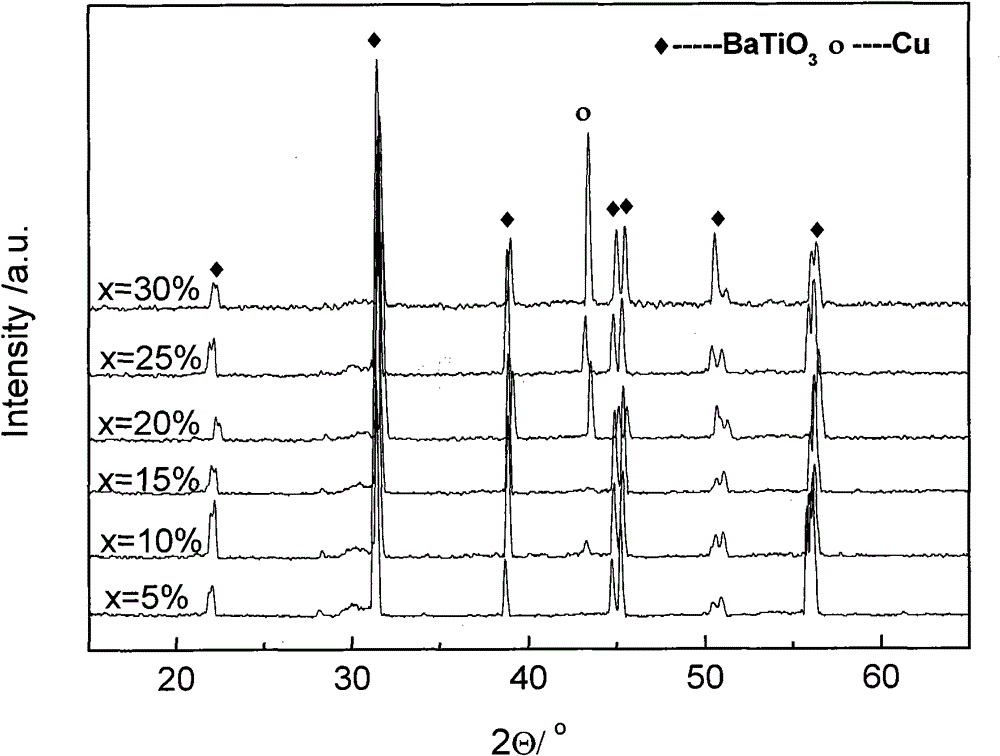

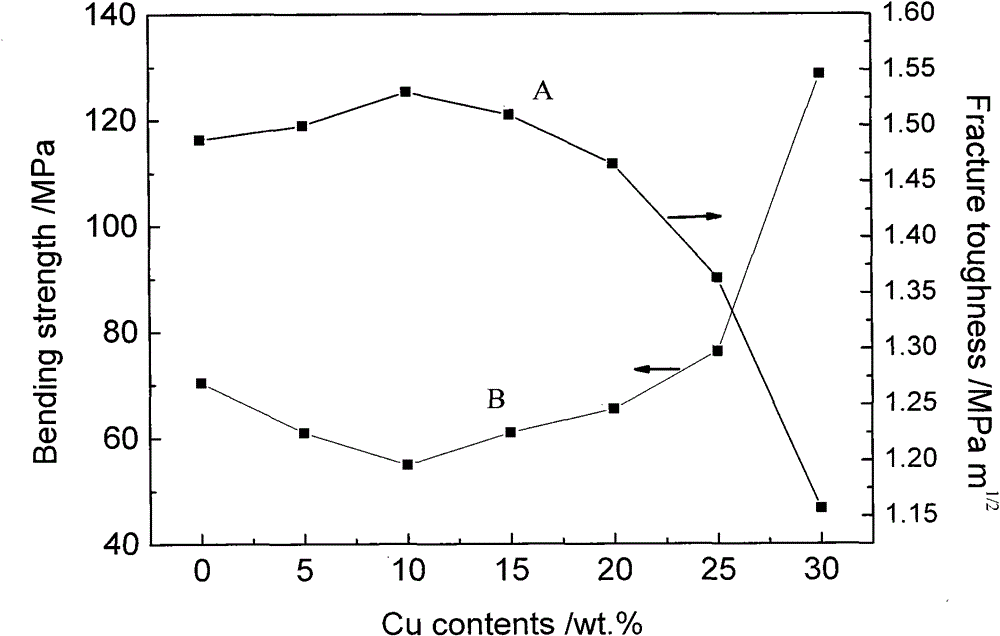

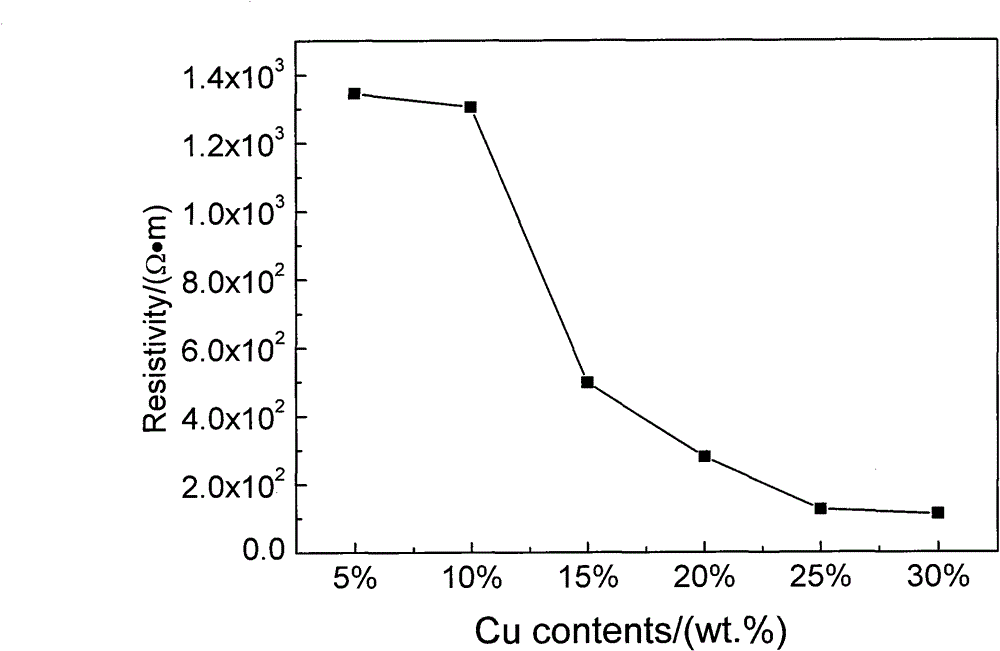

[0034] A method for preparing a high dielectric constant composite material, characterized in that it comprises the following steps,

[0035] In the first step, barium titanate powder and copper powder are used as raw materials, according to BaTiO 3 / xCu, x=30wt.% carry out batching;

[0036] In the second step, the raw material, ball milling medium and ball stone are mixed, and then ball milled on a planetary ball mill for 4 hours in a resin ball mill tank, wherein the mass ratio of raw material, ball milling medium and ball stone is: raw material: ball milling medium: ball stone=1 :1:1.5;

[0037] The third step is to dry the ball-milled slurry in a vacuum oven at a temperature not higher than 50°C, then granulate with PVA with a concentration of 3%, pass the granulated granules through a 150-mesh sieve, and stale for 24 hours;

[0038] The fourth step is to put the stale grains into a steel mold and press them into a cylindrical green body under a pressure of 5MPa, hold t...

Embodiment 2

[0043] A method for preparing a high dielectric constant composite material, characterized in that it comprises the following steps,

[0044] In the first step, barium titanate powder and copper powder are used as raw materials, according to BaTiO 3 / xCu, x=10wt.% carry out batching;

[0045] In the second step, the raw material, ball milling medium and ball stone are mixed, and then ball milled on a planetary ball mill for 4 hours in a resin ball mill tank, wherein the mass ratio of raw material, ball milling medium and ball stone is: raw material: ball milling medium: ball stone=1 :1.2:2;

[0046] The third step is to dry the ball-milled slurry in a vacuum oven at a temperature not higher than 50°C, then use PVA with a concentration of 4% to granulate, pass the granulated granules through a 150-mesh sieve, and stale for 24 hours;

[0047] The fourth step is to put the stale grains into a steel mold and press them into a cylindrical green body under a pressure of 5MPa, hold...

Embodiment 3

[0052] A method for preparing a high dielectric constant composite material, characterized in that it comprises the following steps,

[0053] In the first step, barium titanate powder and copper powder are used as raw materials, according to BaTiO 3 / xCu, x=1wt.% for batching;

[0054] In the second step, the raw material, ball milling medium and ball stone are mixed, and then ball milled on a planetary ball mill for 4 hours in a resin ball mill tank, wherein the mass ratio of raw material, ball milling medium and ball stone is: raw material: ball milling medium: ball stone=1.5 :1.5:2;

[0055] The third step is to dry the ball-milled slurry in a vacuum oven at a temperature not higher than 50°C, then use PVA with a concentration of 5% to granulate, pass the granulated granules through a 150-mesh sieve, and stale for 24 hours;

[0056] The fourth step is to put the stale grains into a steel mold and press them into a cylindrical green body under a pressure of 5MPa, hold the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com