Composite algal polysaccharide-based double-layer packaging film as well as preparation method and application thereof

A technology of seaweed polysaccharide and packaging film, which is applied in the direction of biological packaging, transportation and packaging, sustainable packaging, etc., can solve the problems of reducing the release/volatility rate of essential oils, and achieve obvious inner and outer layer structure, good sealing performance, and good antibacterial effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of sodium alginate-agar-ginger essential oil composite double-layer antibacterial film

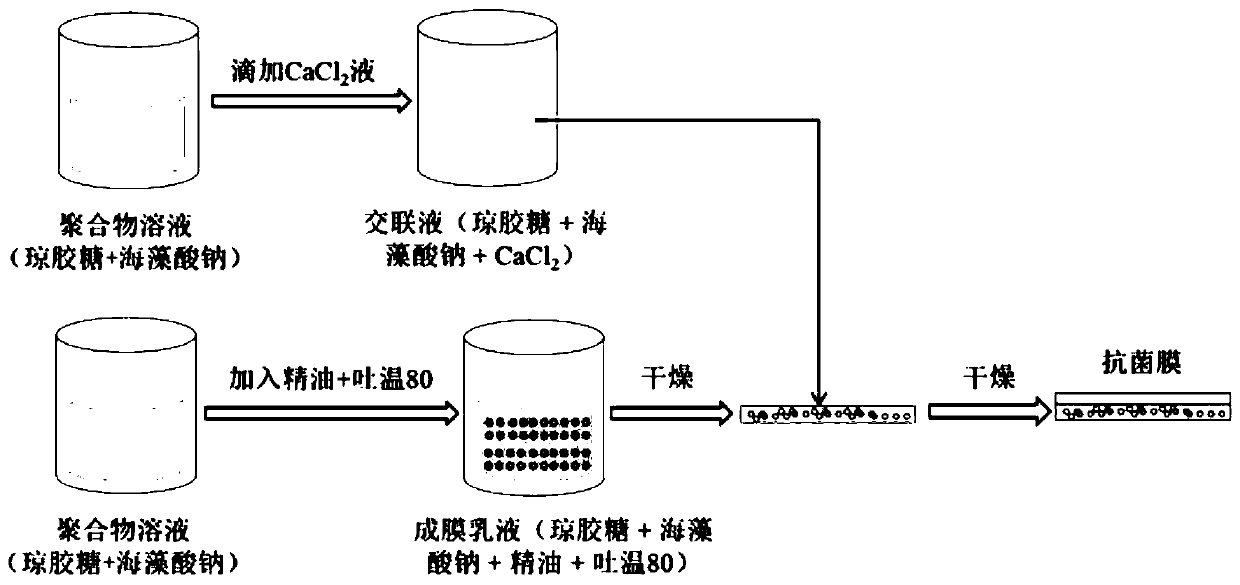

[0038] Process flow chart such as figure 1 As shown, it mainly includes the following steps:

[0039](1) Preparation of agar: select fresh, impurity-free asparagus, dry it, grind it into powder and pass through an 80-mesh sieve, take the powder and add absolute ethanol at a ratio of 1:10 (w / v) to soak overnight, remove the ethanol and dry it. After natural air-drying, extract by hot water reflux method (material-to-liquid ratio 1:60, water temperature 100°C, extraction time 120min, repeat extraction twice); the extract was frozen at -50°C for 12 hours, then redissolved at room temperature, centrifuged (4000rpm, 15 min) to remove the jelly in the lower layer; quickly freeze the jelly at -50°C for 24 hours, and then vacuum freeze-dry to obtain agar;

[0040] (2) Preparation of compound seaweed polysaccharide film-forming solution: weigh a certain quality of ra...

Embodiment 2

[0045] Example 2: Structural characterization and determination of sodium alginate-agar-ginger essential oil composite double-layer antibacterial film

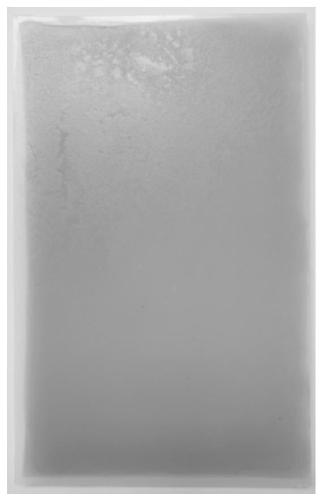

[0046] The sodium alginate-agar-ginger essential oil composite double-layer antibacterial film (a kind of composite seaweed polysaccharide-based double-layer packaging film) prepared in Example 1 is placed in a temperature of 25 ° C and a relative humidity of 50%. Set 48h.

[0047] (1) Scanning electron microscope detection: Take the sodium alginate-agar-ginger essential oil composite double-layer antibacterial film sample that has been balanced, stick it on the conductive adhesive and install it on the sample holder; the cross-section of the film sample is passed through the film in liquid nitrogen Brittle fractures were obtained, which were also pasted on the conductive adhesive and mounted on the sample holder. Spray gold for 15 minutes in a vacuum environment with a sputter coater. Then its surface and cross-sectional mi...

Embodiment 3

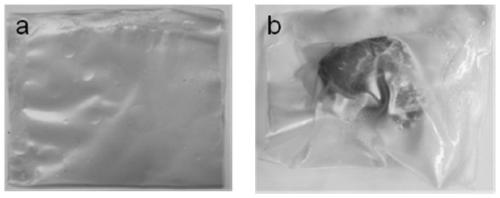

[0056] Example 3: Detection of antibacterial properties of sodium alginate-agar-ginger essential oil composite double-layer antibacterial film

[0057] Bacteriostatic activity assay index evaluation: according to "GB 4789.2-2016" to evaluate the growth of antibacterial film on foodborne pathogenic Gram-positive bacteria (Staphylococcus aureus, Bacillus subtilis) and Gram-negative bacteria (Escherichia coli) Inhibitory effect:

[0058] (1) Strain activation: thaw the medium of Escherichia coli, Staphylococcus aureus, and Bacillus subtilis fused and stored in BHI broth, transfer the medium (0.1mL) to 10mL of BHI broth, and store at 37°C Cultivate in shake flask incubator for 24h;

[0059] (2) Determination of bacterial liquid concentration: the bacterial liquid concentration was determined by the plate dilution method, and the above culture (0.1 mL) was transferred to 10 mL of BHI broth for the second time, and cultured at 37 ° C for 24 h until the end of the growth index stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com