A method of synthesizing polyalphaolefin base oil

A base oil and α-olefin technology, applied in the field of lubricating base oil synthesis, can solve problems such as difficult processing and uneven fluid distribution, achieve high selectivity, save initial investment, and strengthen interphase mass transfer and heat transfer processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

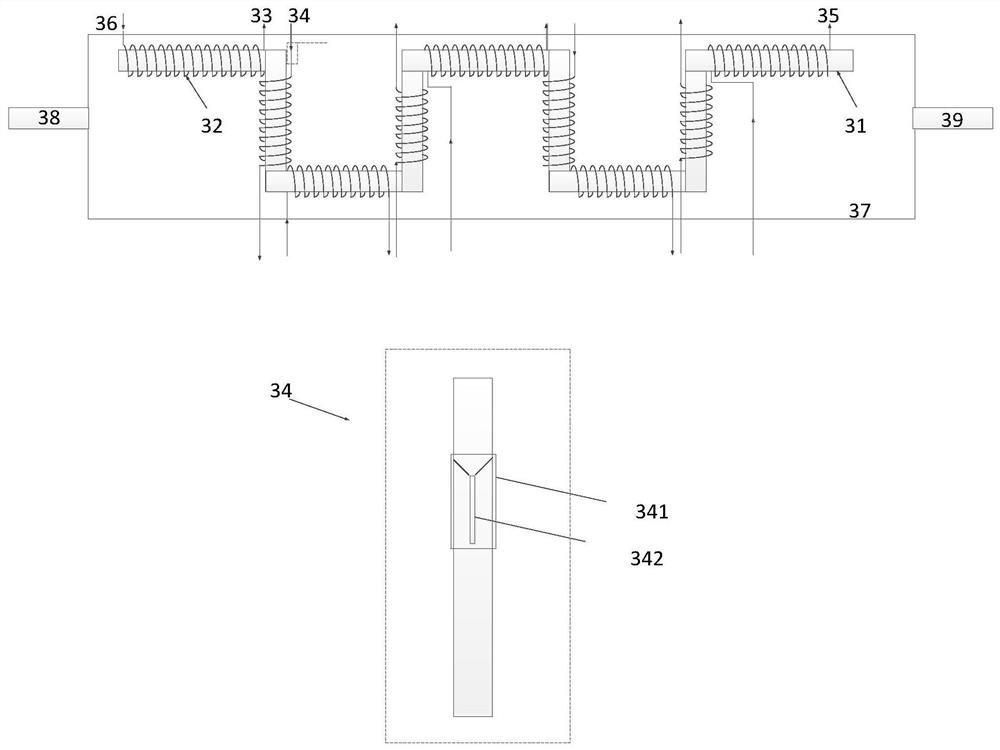

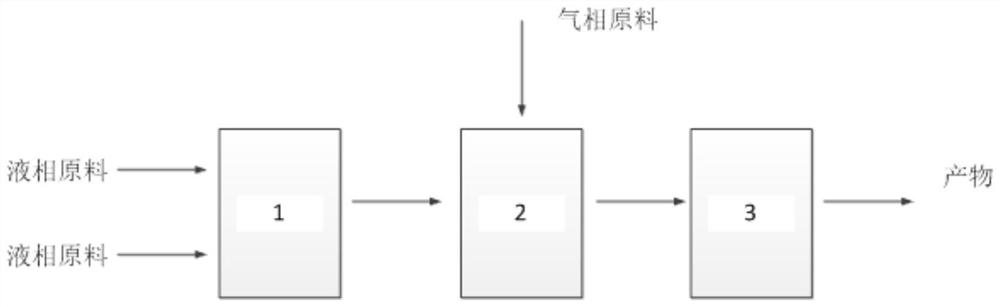

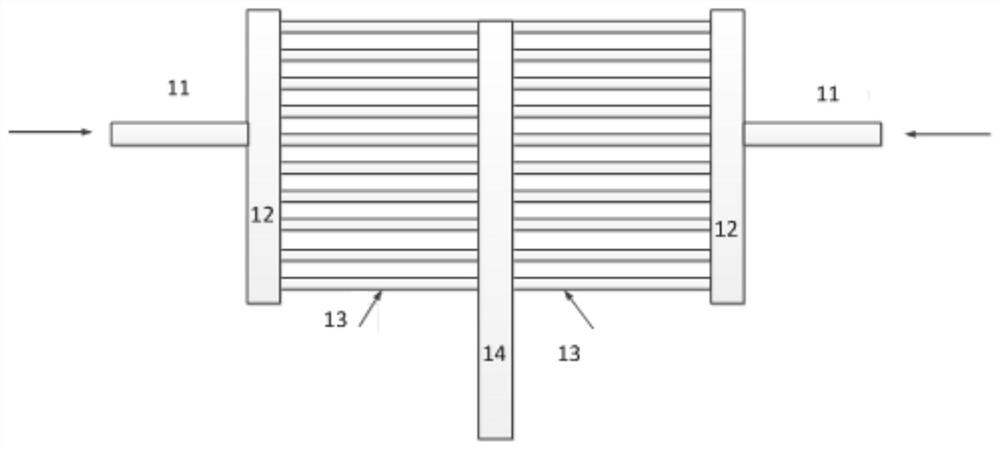

[0148] This embodiment adopts figure 2 The microreactor system shown performs the adsorption desulfurization process of sulfur-containing hydrocarbons, and figure 2 The specific structures of impinging flow microchannel mixer, two-phase microchannel reactor and coil microreactor involved in image 3 , 4 and shown in 1.

[0149] The technical process in this embodiment is as described in the aforementioned preferred specific embodiments of the present invention, and other relevant contents involved are as follows:

[0150] In the impingement flow microchannel mixer 1, the angle between each of the raw material impact microchannels 13 and the material flow impact unit 14 is 90°; the inner diameter of the material impact microchannel 13 is 1mm, and the length is 5mm; The inner diameter of the logistics impact unit 14 is 5mm;

[0151] In the two-phase microchannel reactor 2, the cross-sectional area of the reaction microchannel 25 is 1.5mm 2 , the distance between two adj...

Embodiment 2

[0156] This embodiment adopts the same system as embodiment 1 to carry out, the difference is:

[0157] The reaction temperature in the method of this example is 45° C. and the pressure is 2.5 MPa. And the feed rate of 1-decene in the present embodiment is 12mL / min, and the feed rate of n-butanol is 1.2mL / min, BF 3 The feed rate is 50mL / min, and after the reactant starts to feed for 15min, a stable product discharge is obtained, and the product properties are shown in Table 1.

Embodiment 3

[0159] The present embodiment adopts the system similar to embodiment 1 and carries out with the method identical with embodiment 1, difference is:

[0160] In the coil microreactor of this embodiment, the angles between two adjacent sections of support tubes 31 are both 60°. All the other are the same as in Example 1.

[0161] In the present embodiment, 15 minutes after the feed of the reactant was started, a stable product discharge was obtained, and the properties of the product are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com