Perovskite battery assembly with ultraviolet protection layer and preparation method thereof

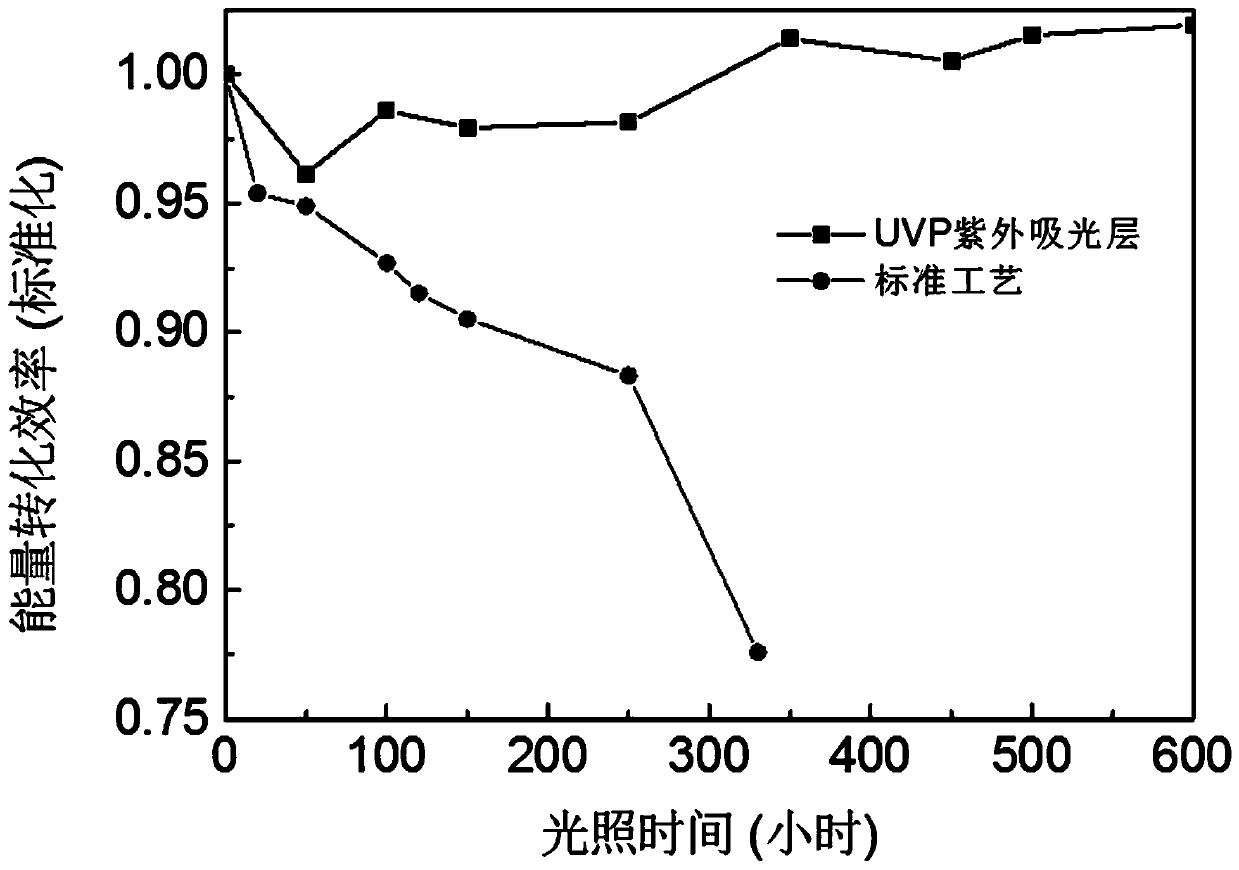

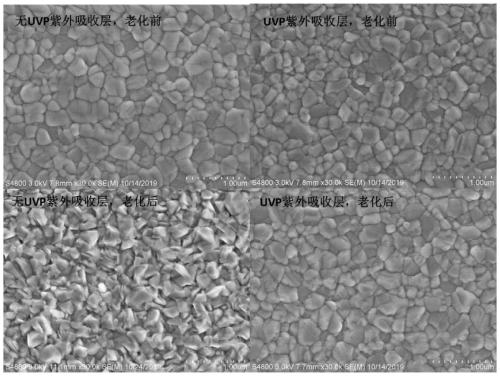

A technology of perovskite cells and protective layers, which can be used in the manufacture of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc. It can improve the stability of UV light and full-spectrum illumination, and eliminate the effect of ion migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention also discloses a preparation method of the perovskite battery assembly with an ultraviolet protective layer—evaporation method, which includes the following steps:

[0022] Step 1. Place the transparent base layer in the vacuum chamber with its back facing the direction of the evaporation source, and use a vacuum pump to control the air pressure in the vacuum chamber for 10 -8 Pa~10 5 Pa, the heating temperature of the transparent base layer is controlled at 25° C. to 250° C.

[0023] Step 2, placing the UVP additive in the evaporation source, controlling the evaporation rate of the UVP additive to 0.05Å / s~2Å / s, and preparing an ultraviolet protective layer containing the UVP additive with a thickness of 1nm~500nm.

[0024] Step 3, sequentially prepare a transparent conductive layer, an upper transport layer, a perovskite light-absorbing layer, a lower transport layer and an electrode layer on the ultraviolet protective layer prepared in step 2, u...

Embodiment 1

[0035] The first perovskite battery assembly with an ultraviolet protective layer of the present invention and an embodiment of its preparation method - evaporation method, comprising the following steps:

[0036] (11) Clean the base layer of a 5cm×5cm transparent glass plate sequentially with detergent, deionized water, acetone, and isopropanol for 30 minutes, and then use N 2 After drying, it was treated with UV O-zone for 10 minutes.

[0037] (12) Place the transparent glass base layer in a vacuum chamber with its back facing the evaporation source, place phenylbenzimidazole sulfonic acid in the evaporation boat, and use a vacuum pump to control the air pressure at 10 -8 Pa~10 5 Pa, control the evaporation rate at 0.05Å / s~2Å / s, and form a UV protective layer with a thickness of 5nm~20nm containing UVP additive phenyl benzimidazole sulfonic acid.

[0038] (13) Prepare an ITO transparent conductive layer on the UV protective layer prepared in (12) by magnetron sputtering. ...

Embodiment 2

[0046] The second perovskite battery component with an ultraviolet protective layer of the present invention and its preparation method embodiment - solution method, comprising the following steps:

[0047] (21) Clean the substrate of a 5cm×5cm transparent glass plate sequentially with detergent, deionized water, acetone, and isopropanol for 30 minutes, and then use N 2 After drying, it was treated with UV O-zone for 10 minutes.

[0048] (22) Dissolve 30 mg of phenylbenzimidazole sulfonic acid in 1 mL of ethanol, place the back of the transparent glass substrate upwards, deposit phenylbenzimidazole sulfonic acid on the back of the transparent glass substrate by scraping method, and anneal at 100°C for 5 minutes Forms a UV protective layer containing UVP additives.

[0049] (23) Prepare an ITO transparent conductive layer on the UV protective layer prepared in (22) by magnetron sputtering.

[0050] (24) Deposit 10 nm of PTAA on the transparent conductive layer by spin coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com