Synchronous shrinkage liner tube for sintering tubular ITO target blank and preparation method thereof

A target blank and liner technology, which is applied in the sintering field of tubular ITO target products, can solve the problems of large differences in sintering shrinkage, shrinkage reduction, and uneven laying, so as to reduce sintering shrinkage resistance and overall density. Uniform distribution, increased density and uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

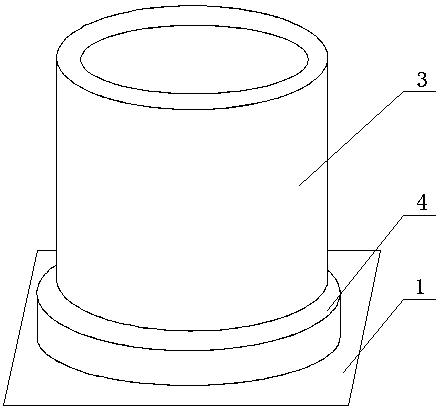

Image

Examples

preparation example Construction

[0027] The synchronous shrinkage liner for sintering the tubular ITO target body and its preparation method provided by the present invention use tetragonal polycrystalline zirconia powder or barium strontium titanate powder as raw materials to prepare the liner suitable for The tetragonal polycrystalline zirconia synchronous shrinkage liner or the strontium barium titanate synchronous shrinkage liner with the sintering shrinkage rate of the tubular ITO target body can produce a synchronous shrinkage effect during sintering, thereby improving the quality of the sintered body. Its preparation method comprises the following steps:

[0028] Step 1. Ball milling: the specific surface area is 15~25m 2 g -1 tetragonal polycrystalline zirconia powder, or a specific surface area of 18~30m 2 g -1 The strontium barium titanate powder is used as raw material, and deionized water is added according to the target solid phase content of the slurry at 50%, and ammonia water with a conce...

Embodiment 1

[0035] Synchronous shrinkage liner for sintering of tubular ITO target green body, the preparation steps are as follows:

[0036] With a specific surface area of 25m 2 g -1The tetragonal polycrystalline zirconia powder is used as a raw material, and deionized water is added according to the target solid phase content of the slurry at 50%, and ammonia water with a concentration of 25% is used as a dispersant to adjust the pH value of the premix to 9, and add 1.0% of the mass of the raw material The binder PVA is mixed evenly, and then placed in a roller mill for ball milling and mixing. The lining of the ball mill tank is zirconia, and the grinding balls are zirconia balls with a diameter of 10mm. The ratio of balls to materials is 1:1, and the speed of the ball mill is 100r / min, the ball milling time is 5h, the viscosity of the tetragonal polycrystalline zirconia slurry after ball milling is 25mPa s (the rotational speed of the rotational viscometer at room temperature is ...

Embodiment 2

[0040] Synchronous shrinkage liner for sintering of tubular ITO target green body, the preparation steps are as follows:

[0041] With a specific surface area of 25m 2 g -1 The barium strontium titanate powder is used as raw material, and deionized water is added according to the target solid phase content of the slurry at 50%, ammonia water with a concentration of 25% is used as a dispersant, the pH value of the premix is adjusted to 10, and 1.2% of the powder is added The binder PVA is mixed evenly, and then placed in a roller ball mill for ball milling and mixing. The selected ball mill tank is lined with wear-resistant polyurethane, the grinding balls are zirconia balls with a diameter of 15mm, the ball-to-material ratio is 2:1, and the ball mill speed is 150r / min, the ball milling time is 8h, the viscosity of strontium barium titanate slurry after ball milling is 27mPa s (the rotation speed of the rotational viscometer at room temperature is 20s -1 ). The strontiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com