A magnetic microsphere with functional groups on its surface, its preparation method and application

A functional group, magnetic microsphere technology, applied in the field of material chemical industry, can solve the problems of magnetic flux leakage, uneven surface hydrophilicity and hydrophobicity, good consistency, high magnetic content, and achieve rich surface functional groups, good consistency, magnetic high content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Preparation method of magnetic microspheres:

[0089] (1) Polystyrene microspheres were prepared by soap-free emulsion polymerization, and the specific synthesis method was as follows:

[0090] (a) Add 500mL of deionized water and 50mL of styrene into a 1L three-necked flask, and stir for 10 minutes under nitrogen at room temperature at a speed of 200r / min;

[0091] (b) Add 1.0 g of potassium persulfate to 50 ml of deionized water, and ultrasonically dissolve;

[0092] (c) Pour the potassium persulfate solution in step (b) into the solution in (a), heat up to 80° C., stir for 24 hours, and rotate at a speed of 200 r / min to obtain polystyrene microspheres;

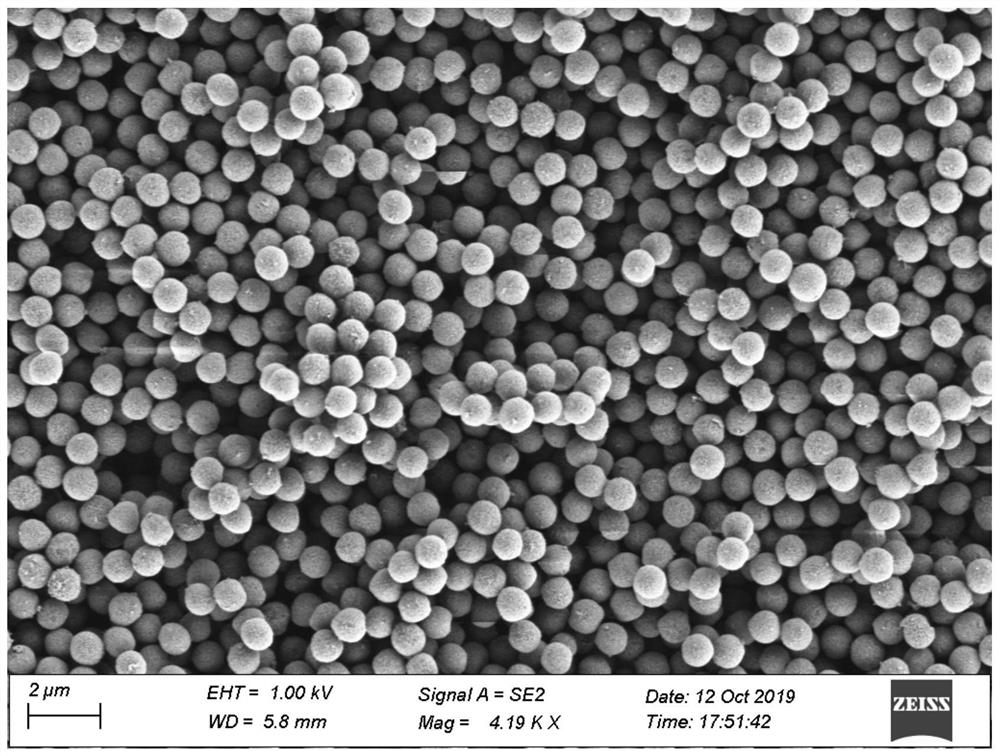

[0093] The particle size of the prepared polystyrene microspheres is about 700 nanometers;

[0094] (II) carrying out nitration reaction on the surface of the polymer microspheres prepared in step (I), specifically comprising the following steps:

[0095] (a') 95% concentrated sulfuric acid of 900g and 65% concent...

Embodiment 2

[0106] The difference between this embodiment and Example 1 is that in step (Ⅲ), the sodium citrate solution is replaced with an equal volume of polyethylene glycol solution (polyethylene glycol in the polyethylene glycol solution is mixed with the above sodium citrate solution). The molar weight of the sodium citrate is identical), other conditions are compared with embodiment 1 and are exactly the same.

Embodiment 3

[0108] The difference between this embodiment and embodiment 1 is that the equimolar amount of methacrylic acid in step (V) is replaced by ethyl acrylate, and other conditions are completely the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com