Chemo-mechanical polishing solution

A chemical-mechanical and polishing liquid technology, applied in the field of chemical-mechanical polishing, can solve the problems of copper residue, dielectric layer erosion, copper wire dish-shaped depression, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

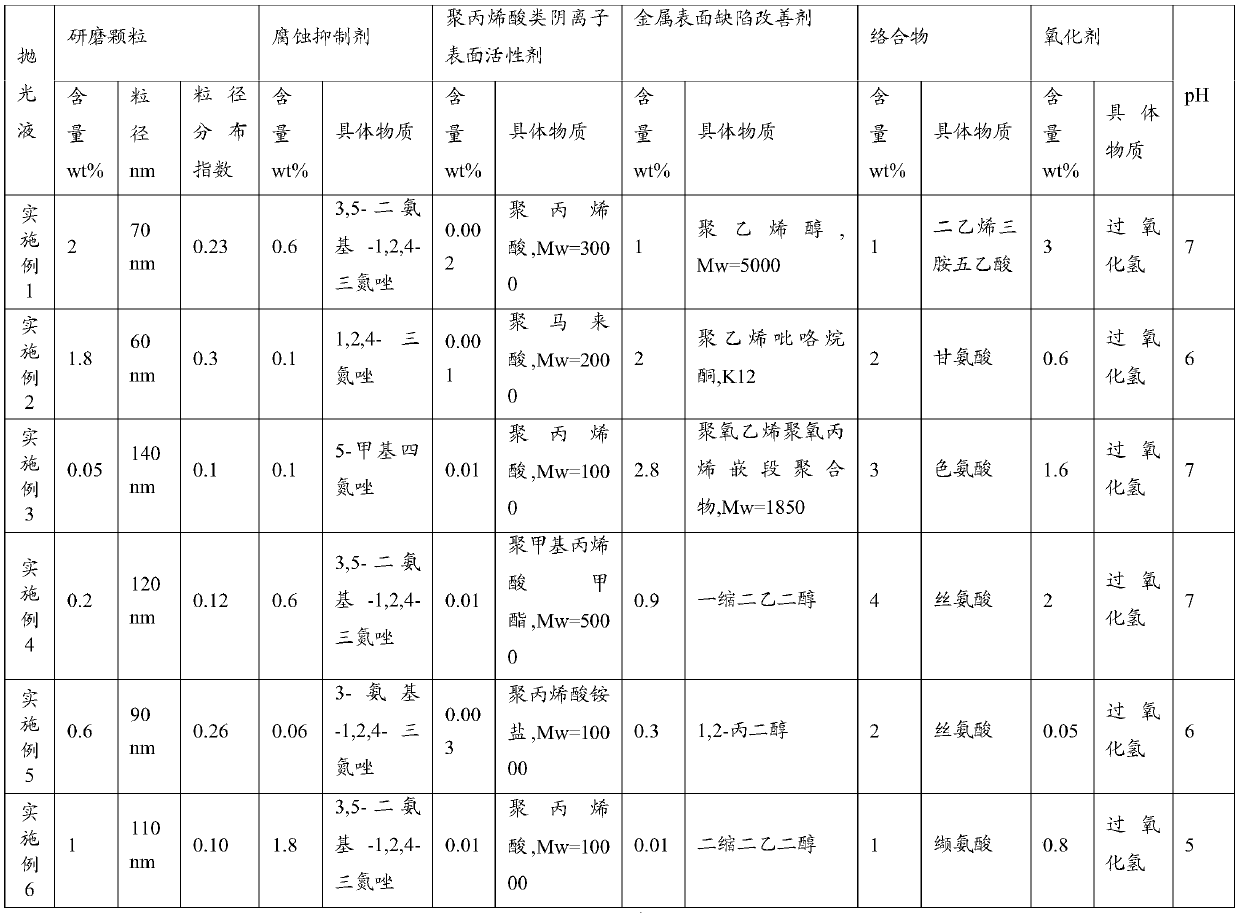

[0041] The advantages of the present invention are further described below through specific examples, but the protection scope of the present invention is not limited only to the following examples.

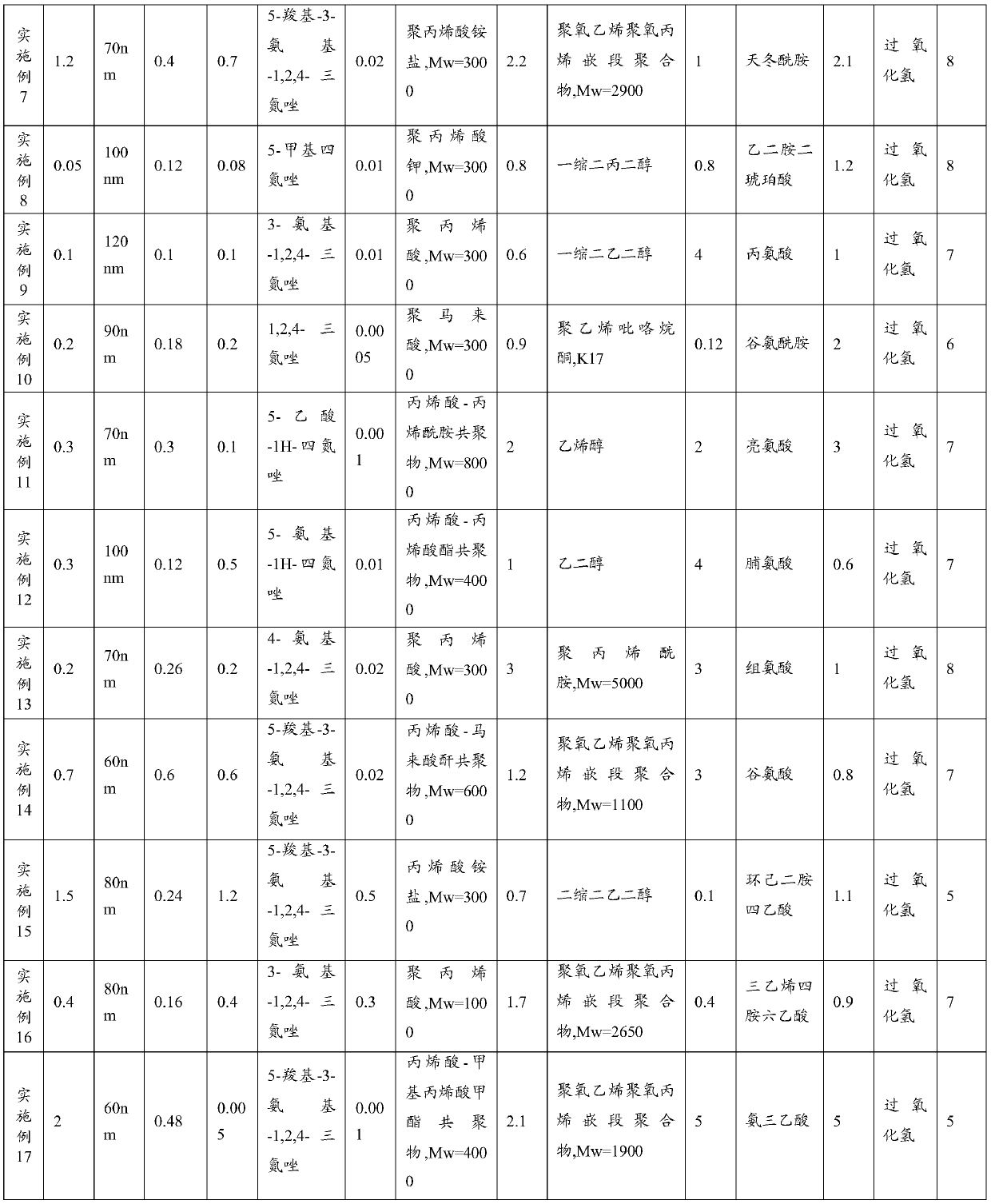

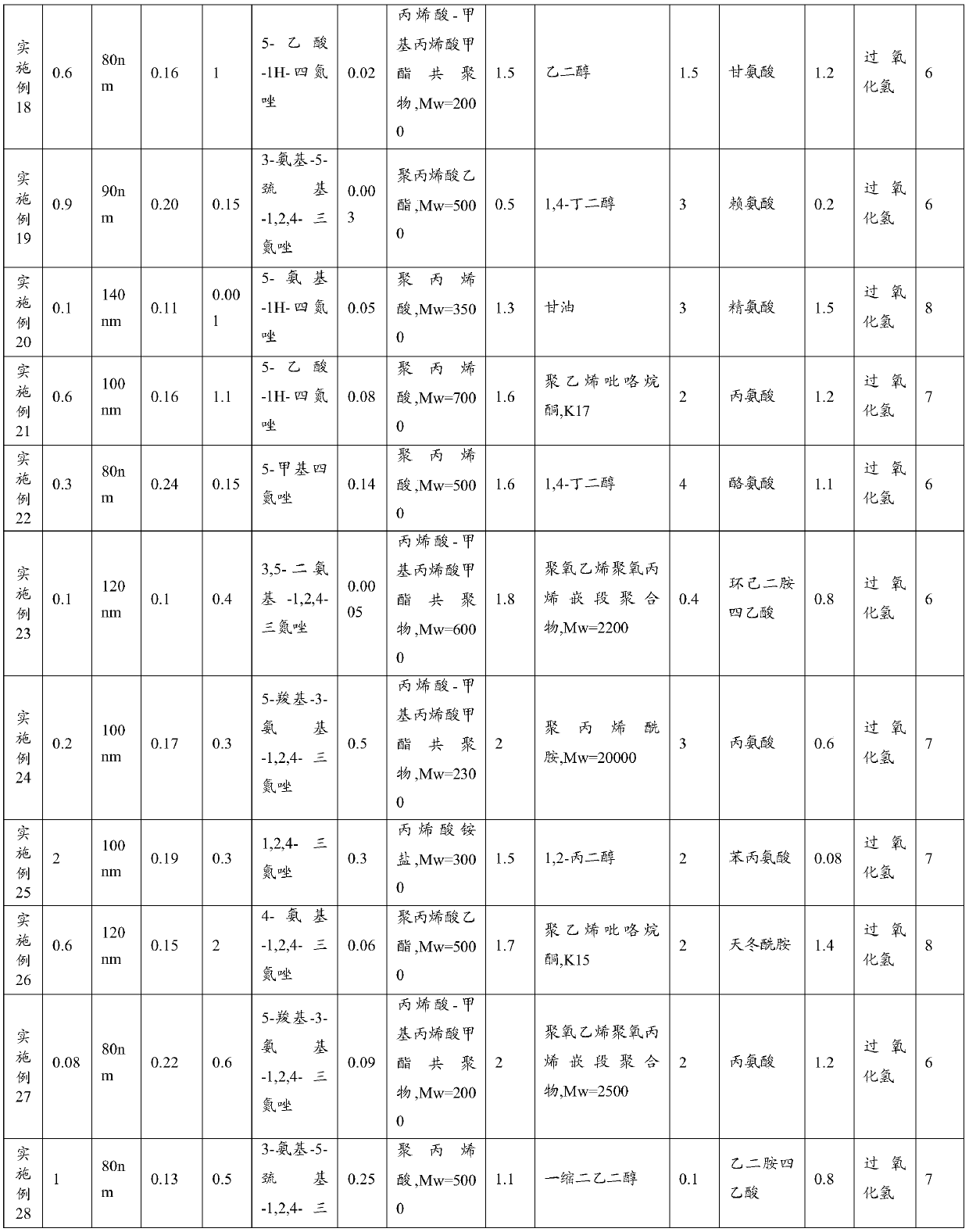

[0042] Table 1 shows examples 1-28 of the chemical mechanical polishing fluid of the present invention. According to the formula given in the table, the other components except the oxidizing agent were mixed evenly, and the mass percentage was made up to 100% with water. with KOH or HNO 3 Adjust to desired pH. Add oxidant before use and mix evenly. The polishing liquid of the present invention can also be prepared into a concentrated sample first, diluted with deionized water, and added with an oxidizing agent for use.

[0043] Table 1 Polishing liquid composition of the present invention embodiment 1~28

[0044]

[0045]

[0046]

[0047]

[0048]Table 2 shows the examples 29-41 and comparative examples 1-8 of the chemical mechanical polishing liquid of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com