Preparation method and application method of Cr<3+> doped near-infrared wide-spectrum luminescent material

A luminescent material and near-infrared technology, applied in luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems of low luminous efficiency and narrow range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: The chemical composition formula of this embodiment is Ca 3 Y 1.98 Ge 3 o 12 : 0.02Cr 3+ The specific preparation method of the broad-spectrum near-infrared luminescent material is as follows:

[0032] According to the chemical composition formula Ca 3 Y 1.98 Ge 3 o 12 : 0.02Cr 3+ Stoichiometric ratio, respectively weigh CaO, Y 2 o 3 , GeO 2 、Cr 2 o 3 High-purity raw materials and 3% flux LiF are placed in an agate mortar and an appropriate amount of ethanol is added for grinding for 20-40 minutes to fully mix the raw materials evenly. After drying, transfer the mixed raw materials to an alumina crucible and put In a high-temperature box-type furnace, heat up to 1400°C at a heating rate of 10°C / min, hold for 6 hours, cool to room temperature with the furnace, and regrind into powder. Afterwards, the obtained sample Beijing stock is acid-washed to remove a small amount of impurities, and the chemical composition formula can be obtained as Ca ...

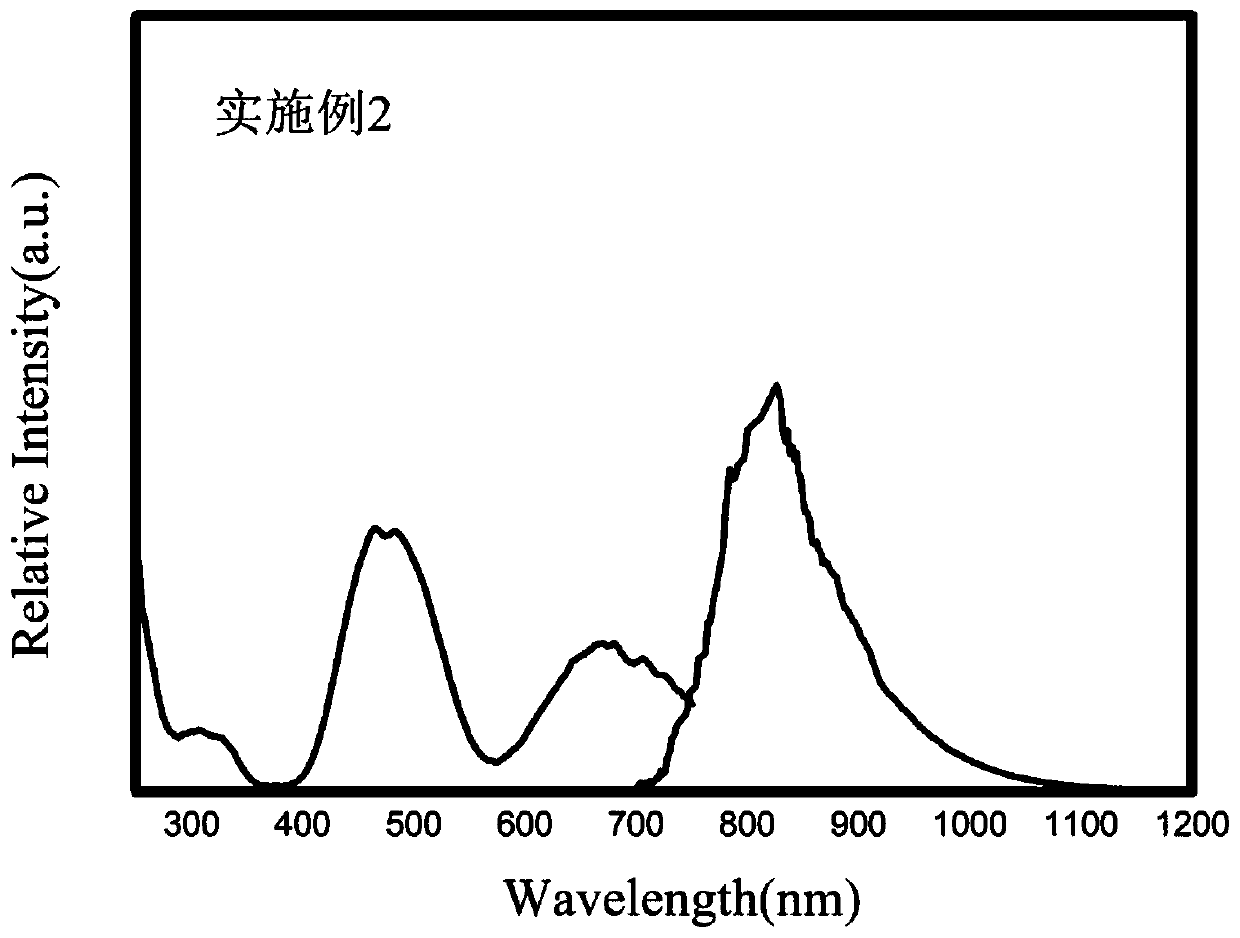

Embodiment 2

[0033] Embodiment 2: The chemical composition formula of this embodiment is Ca 3 Y 1.96 Ge 3 o 12 : 0.04Cr 3+The specific preparation method of the broad-spectrum near-infrared luminescent material is as follows:

[0034] According to the chemical composition formula Ca 3 Y 1.96 Ge 3 o 12 : 0.04Cr 3+ Stoichiometric ratio, respectively weigh CaO, Y 2 o 3 , GeO 2 、Cr 2 o 3 High-purity raw materials and 3% flux LiF are placed in an agate mortar and an appropriate amount of ethanol is added for grinding for 20-40 minutes to fully mix the raw materials evenly. After drying, transfer the mixed raw materials to an alumina crucible and put In a high-temperature box-type furnace, heat up to 1400°C at a heating rate of 10°C / min, hold for 6 hours, cool to room temperature with the furnace, and regrind into powder. Afterwards, the obtained sample Beijing stock is acid-washed to remove a small amount of impurities, and the chemical composition formula can be obtained as Ca 3...

Embodiment 3

[0035] Embodiment 3: The chemical composition formula of this embodiment is Ca 3 Y 1.94 Ge 3 o 12 : 0.06Cr 3+ The specific preparation method of the broad-spectrum near-infrared luminescent material is as follows:

[0036] According to the chemical composition formula Ca 3 Y 1.94 Ge 3 o 12 : 0.06Cr 3+ Stoichiometric ratio, respectively weigh CaO, Y 2 o 3 , GeO 2 、Cr 2 o 3 High-purity raw materials and 3% flux LiF are placed in an agate mortar and an appropriate amount of ethanol is added for grinding for 20-40 minutes to fully mix the raw materials evenly. After drying, transfer the mixed raw materials to an alumina crucible and put In a high-temperature box-type furnace, heat up to 1400°C at a heating rate of 10°C / min, hold for 6 hours, cool to room temperature with the furnace, and regrind into powder. Afterwards, the obtained sample Beijing stock is acid-washed to remove a small amount of impurities, and the chemical composition formula can be obtained as Ca ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com