Substrate-triggered directional solidification of single crystal superalloys

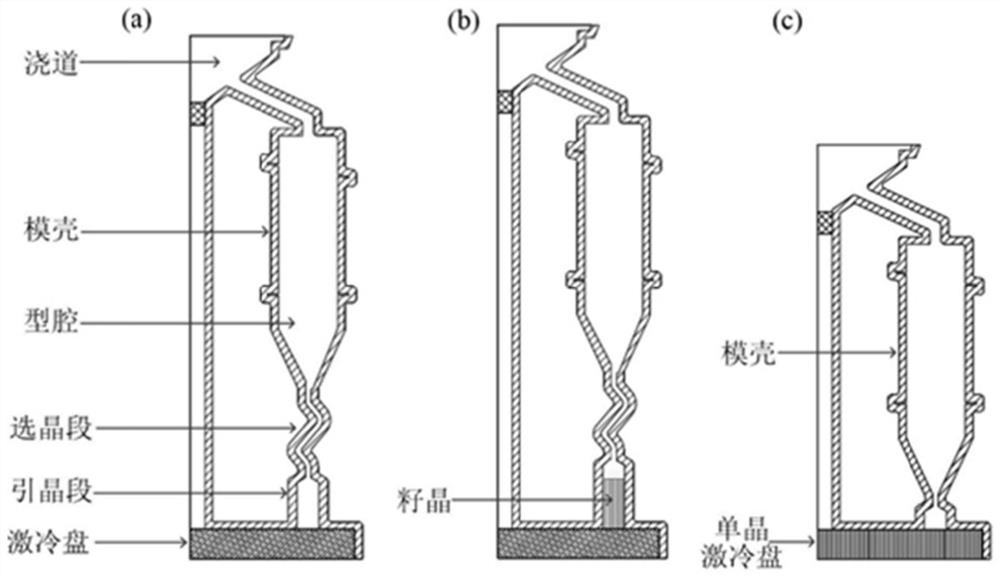

A high-temperature alloy, directional solidification technology, applied in the direction of single crystal growth, single crystal growth, self-solidification method, etc., to achieve the effect of eliminating excessive deviation angle, simplifying process flow and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036]In this example, DD5 superalloy is used to prepare a certain type of single crystal turbine blade, the main alloying elements of which are C (0.040-0.060), Cr (6.75-7.25), Co (7.00-8.00), W (4.75-5.25), Al (6.00~6.40), Ta(6.30~6.70), Mo(1.30~1.70), Hf(0.12~0.18), B(0.003~0.005), Re(2.75~3.25), and the rest are nickel.

[0037] The specific implementation steps are as follows:

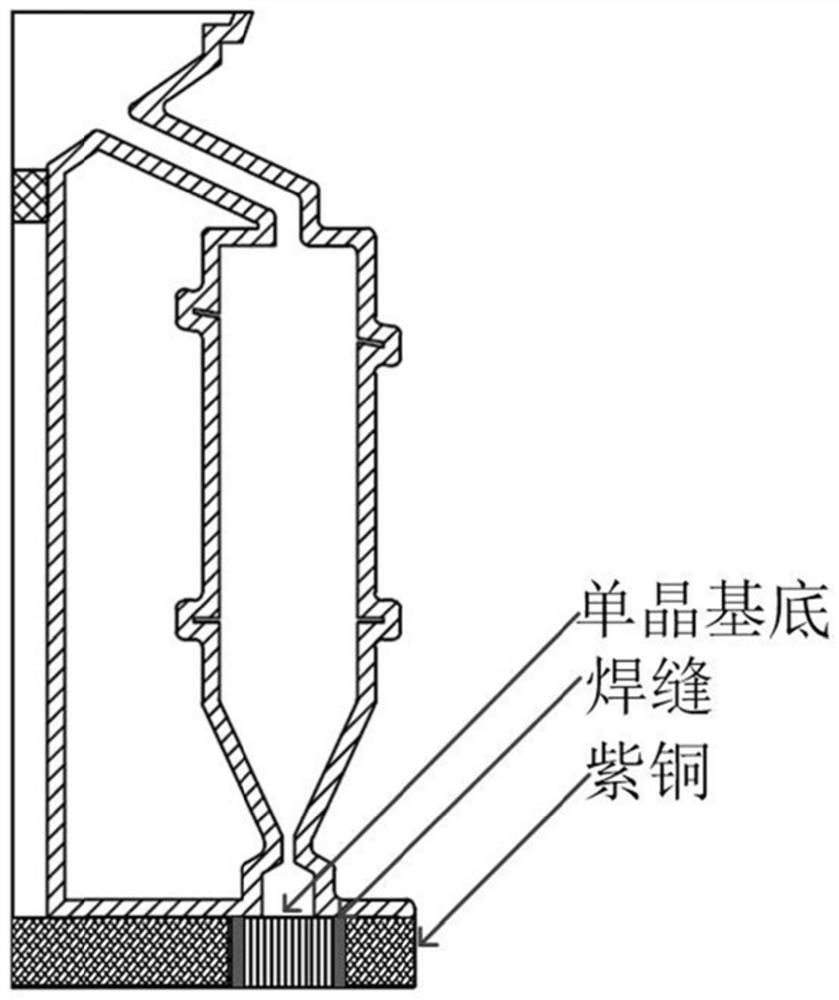

[0038] (1) Preparation of single crystal substrate materials matching the crystallographic characteristics of single crystal superalloys

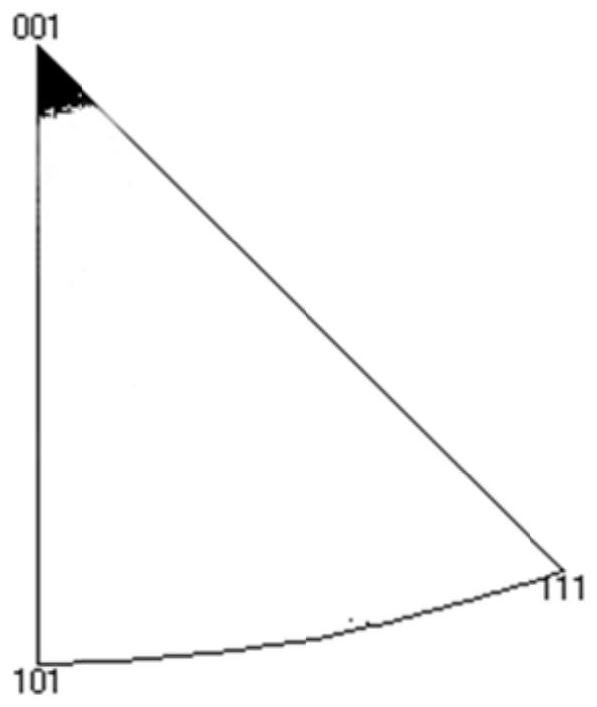

[0039] In this embodiment, DD5 alloy is selected as the single crystal substrate material: (a) Since both the single crystal superalloy and the single crystal substrate material use DD5 alloy, the lattices between the two are completely matched, and the lattice mismatch degree is ≤7.8%; (b) The crystal plane of DD5 single crystal base material in contact with the superalloy melt is (001), which belongs to the low-index crystal plane of the face-centered cubic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com