Processing technology of invisible fingerprint film layer

A processing technology and invisible fingerprint technology, which is applied in the processing technology field of vapor-depositing an invisible fingerprint film layer on a glass cover, can solve the problem of affecting product quality, optimizing customer experience, interfering with glass refractive index and reflectivity, and reducing glass optical performance. and other issues, to achieve the effect of improving processing yield, shortening coating time, and improving bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

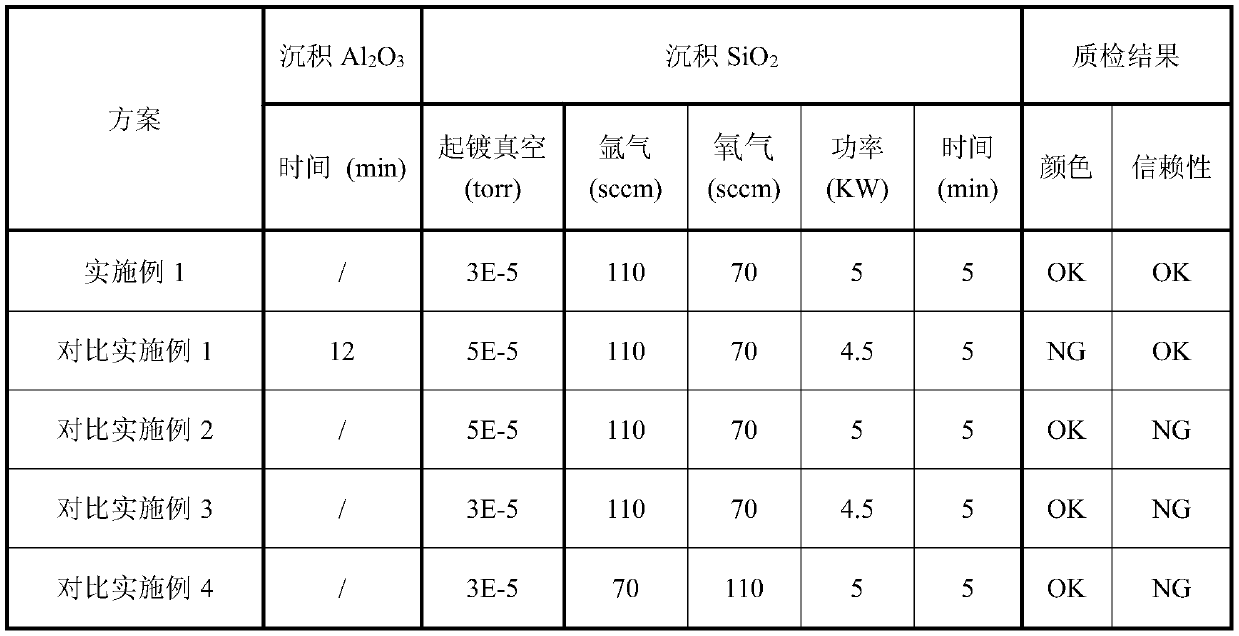

Embodiment 1

[0027] A process for processing an invisible fingerprint film layer, in which an IF film is coated on the surface of aluminosilicate glass, the specific process is as follows:

[0028] Step 1) Ion source cleaning: place the jig carrying the glass product to be coated in the vacuum chamber, evacuate the chamber to 8E-5torr, and generate plasma with a voltage of 790V to bombard the glass surface under the condition of argon gas flow rate of 1000sccm. Realize the cleaning of the glass surface, the cleaning time is 300s;

[0029] Step 2) Sputter deposition of SiO 2 : Evacuate the vacuum in the cavity to 3E-5torr, under the conditions of argon flow rate of 110sccm and oxygen flow rate of 70sccm, the silicon molecules in the silicon target are sputtered out with a sputtering power of 5000W, and the silicon molecules react with oxygen Form SiO 2 and deposited on the glass surface to form SiO 2 layer;

[0030] Step 3) evaporative deposition of IF: the IF film material is heated in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com