Manufacturing method for oleophilic non-stick cooker

A production method and technology for cooking utensils, which are applied in kitchen utensils, household utensils, anodizing and other directions, can solve problems such as harmful carcinogens to the human body, and achieve the effects of avoiding injury, improving service life and improving use safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

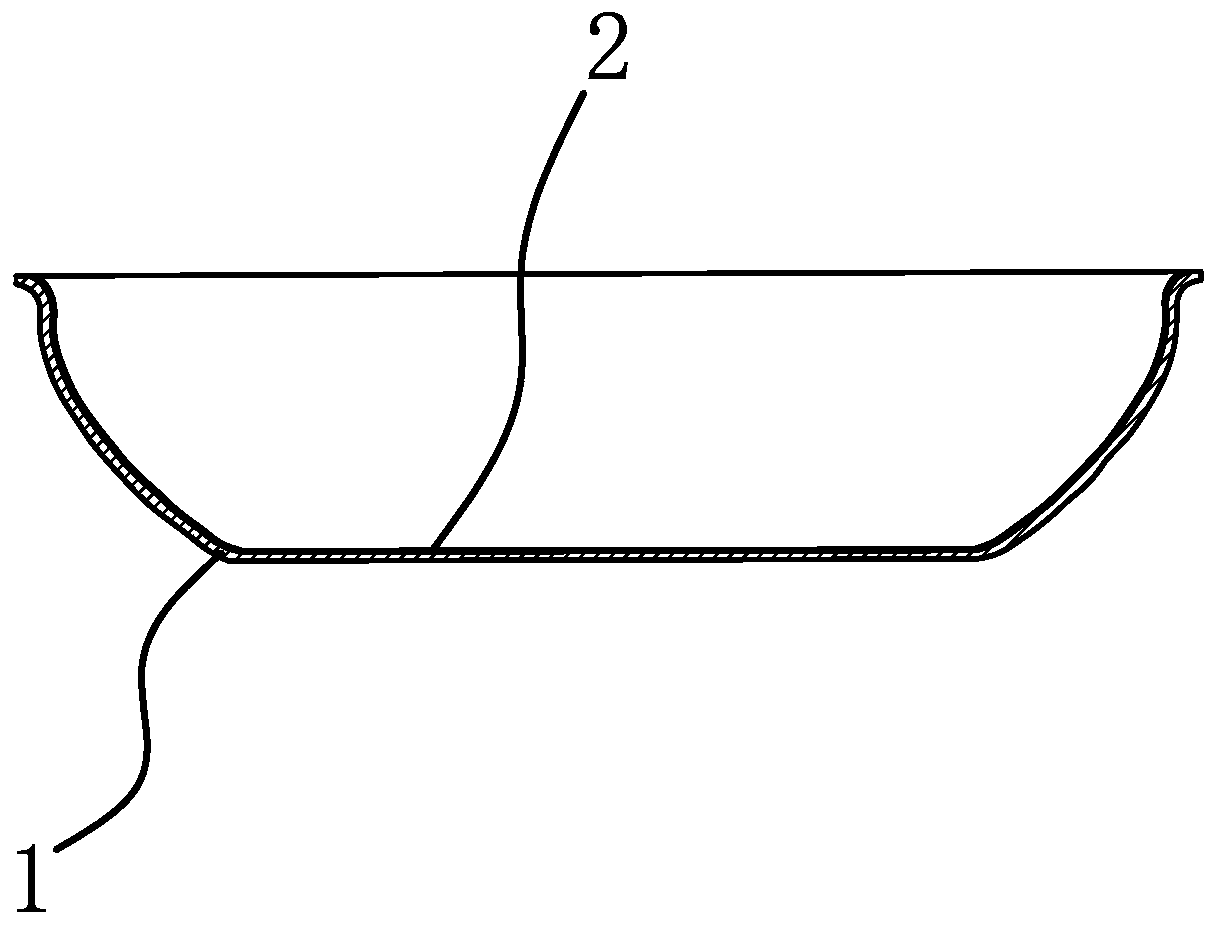

[0037] Such as figure 1 with figure 2As shown, the production method of the lipophilic and non-stick cookware is processed for aluminum alloy cookware to form cookware with good lipophilicity and non-stick properties, which specifically includes the following steps:

[0038] a. Prepare the cooker: prepare the cooker body 1 for molding;

[0039] The formed aluminum alloy cooker body 1 can be processed by deep drawing, spinning, casting and other processes, wherein the aluminum alloy selected for processing such as deep drawing and spinning is 3XXX series aluminum-manganese alloys, such as 3003, 3103A, 3004, etc. Casting and other methods must use cast aluminum alloys with a silicon content (Si)<8%, and the inner surface of the cast cookware must be turned to remove the oxide scale formed during the casting process. In addition, it is also possible to purchase directly from the market without producing it yourself.

[0040] a1. Perform mechanical treatment on the surface of ...

Embodiment 2

[0068] The scheme of this embodiment is roughly the same as that of Embodiment 1, except that the cooking utensil body 1 adopts a frying pan with a diameter of 26 cm, the material is 3103A aluminum alloy, the forming method is deep drawing, the inner surface is finely sanded, and a sulfuric acid hard anode is used Oxidation treatment, the flame temperature is 1800 degrees Celsius, using propane-pure oxygen as fuel, the burning time is 6 seconds per square decimeter of surface, and the flame is moved repeatedly for about 30 seconds, and the cooker body is kept at 1 Cover with soybean oil at 500°C.

Embodiment 3

[0070] The scheme of this embodiment is roughly the same as that of Embodiment 1, except that the cooking utensil body 1 is a frying pan with a diameter of 32 cm, the material is 3103A aluminum alloy, the forming method is spinning, the inner surface is finely sanded, and a sulfuric acid hard anode is used. Oxidation treatment, the flame temperature is 1200 degrees Celsius, using liquefied petroleum gas-pure oxygen as fuel, the burning time is 9 seconds per square decimeter of surface, and the flame is burned repeatedly for about 75 seconds. Cover with soybean oil at 400C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com