Cu-containing industrial sludge hazardous waste resourceful treatment system and treatment method thereof

A technology for industrial sludge and treatment systems, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as waste of resources, and achieve the effect of high degree of automation and good operation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

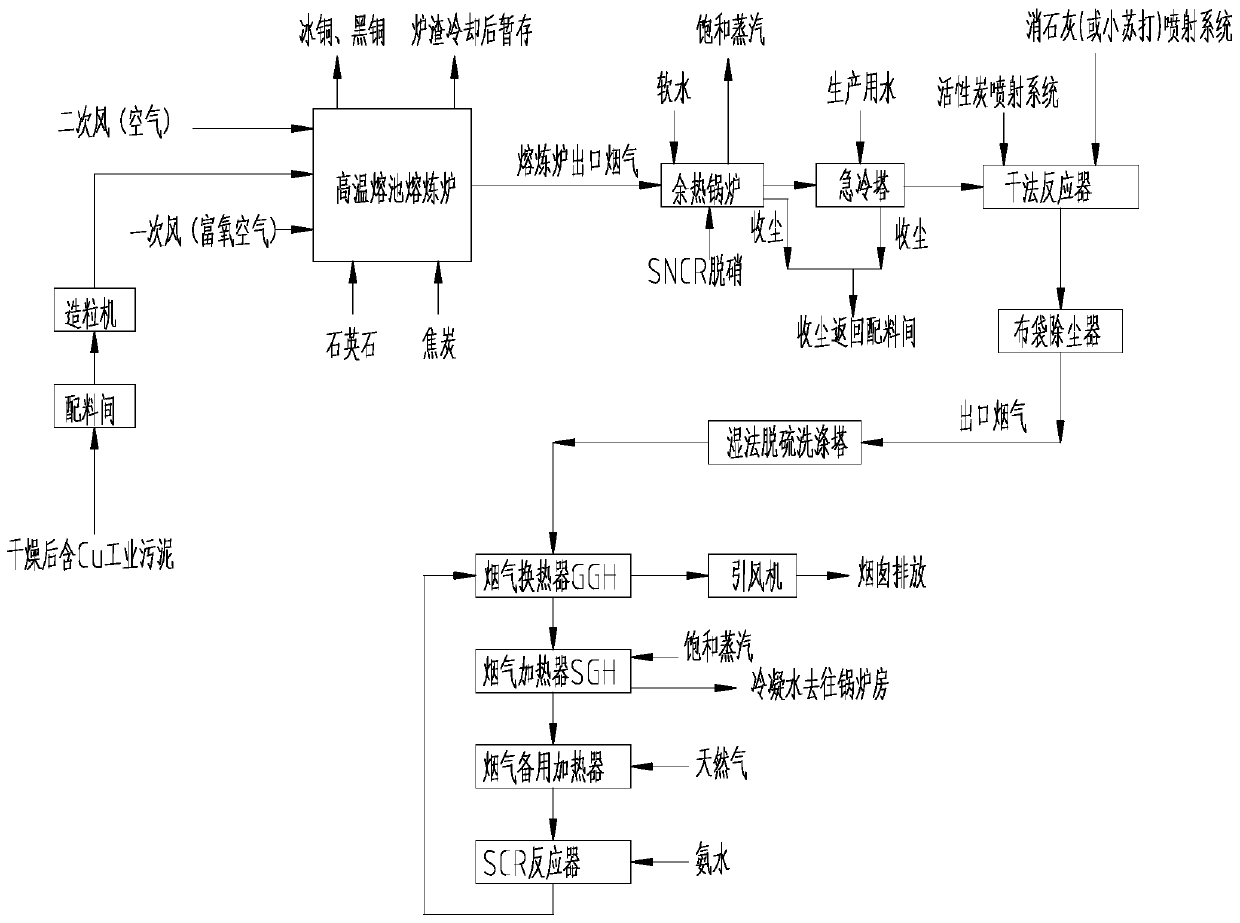

[0033] Such as figure 1 As shown, a hazardous waste resource treatment system containing Cu industrial sludge includes a batching room, a granulator, a smelting furnace, a waste heat boiler, and a flue gas treatment system.

[0034] Specifically, in this embodiment, the flue gas treatment system includes a quench tower, a dry reactor, a bag filter, a wet desulfurization scrubber, a flue gas heat exchanger, a flue gas heater, a flue gas backup heater, and an SCR reaction device;

[0035] The quench tower is connected to the dry reactor pipe, the dry reactor is connected to the bag filter, the bag filter is connected to the wet desulfurization scrubber, and the wet desulfurization scrubber exchanges heat with the flue gas The lumen of the flue gas heat exchanger communicates with the lumen of the flue gas backup heater, the lumen of the flue gas backup heater communicates with the SCR reactor pipeline, and the SCR reactor It communicates with the shell cavity pipeline of the f...

Embodiment 2

[0050] A method for recycling hazardous waste from industrial sludge containing Cu, using the system for recycling hazardous waste from industrial sludge containing Cu in Example 1, comprising the following steps:

[0051] Step S01, batching the Cu-containing industrial sludge in the batching room, and after controlling the humidity of the sludge to 35%, enter the granulator for granulation, so that the Cu industrial sludge becomes granular;

[0052] Step S02, adding granular Cu-containing industrial sludge into the smelting furnace, adding a slagging agent and a reducing agent, and entering the smelting furnace; the temperature in the smelting furnace is 1300°C, and 55% oxygen-enriched air is blown in at the same time;

[0053] The matte and black copper produced by smelting are used as products;

[0054] The water-quenched slag formed after the slag is water-cooled is used as a building material;

[0055] Step S03, the high-temperature flue gas produced by smelting is disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com