Ecological slow-release carbon source, and preparation method and application thereof

A slow-release carbon source and ecological technology, applied in chemical instruments and methods, biological water/sewage treatment, special compound water treatment, etc. and other problems, to achieve the effect of long-term release, reduced degree of polymerization, and increased surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This example provides an ecological slow-release carbon source and its preparation method.

[0041] Step 1: Preliminary pretreatment and cutting of corn stalks, with a diameter screening specification of 2 ± 0.2 cm, cleaned and air-dried, to be processed;

[0042] Step 2, take 10 parts by weight of the sample, and the heating rate is 8°C·min -1 Medium and low temperature dry distillation treatment (temperature is 165°C), and then pyrolysis in water for 60 minutes (pyrolysis temperature is 200°C);

[0043] Step 3, cool the sample after the pyrolysis treatment in step 2 to room temperature, dry to constant weight, obtain the basic slow-release carbon source, fix 3 parts by weight of denitrifying bacteria liquid in the basic slow-release carbon source, and obtain the ecological slow-release carbon source. release carbon source.

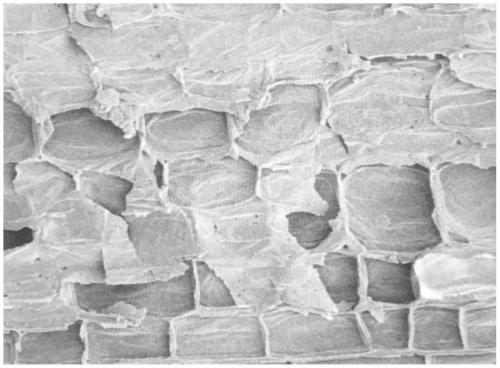

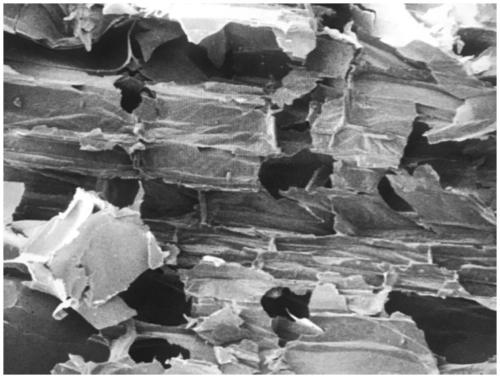

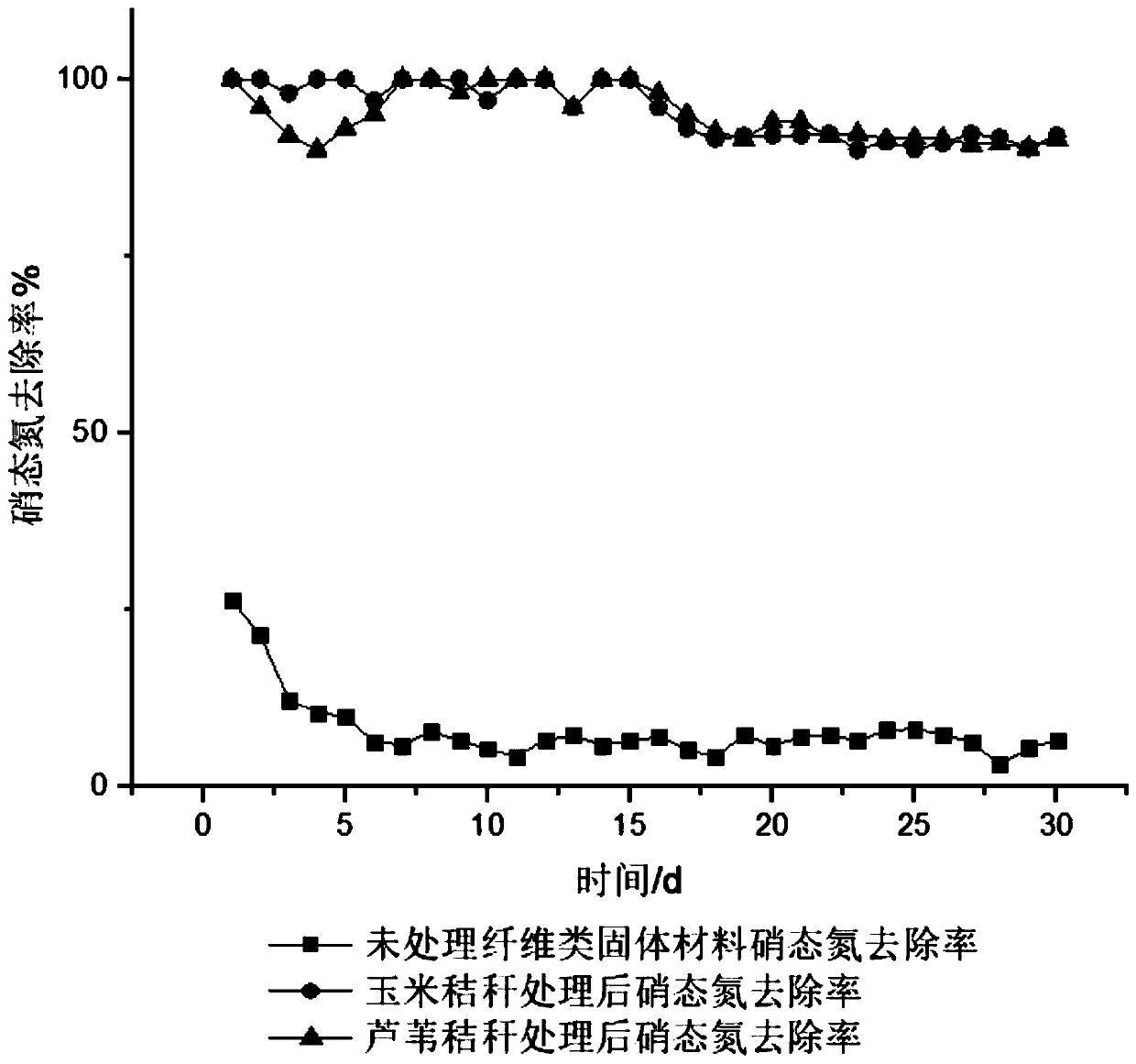

[0044] figure 1 A scanning electron micrograph showing the organizational structure of unmodified corn stalks, figure 2 Shown is the scanni...

Embodiment 2

[0046] This example provides an ecological slow-release carbon source and its preparation method.

[0047] Step 1: Preliminary pretreatment and cutting of the reed stalks, with a diameter screening specification of 1 ± 0.2 cm, cleaned and air-dried, to be processed;

[0048] Step 2, take 20 parts by weight of the sample, and the heating rate is 12°C·min -1 Medium and low temperature dry distillation treatment (temperature is 160°C), and then pyrolysis in water for 30min (pyrolysis temperature is 200°C);

[0049] Step 3, cool the sample after the pyrolysis treatment in step 2 to room temperature, dry to constant weight, obtain the basic slow-release carbon source, fix 5 parts by weight of denitrifying bacteria liquid in the basic slow-release carbon source, and obtain the ecological slow-release carbon source. release carbon source.

[0050]The prepared slow-release carbon source is fine and compact, and the structure of cellulose, hemicellulose and lignin is stable. The stru...

Embodiment 3

[0052] This example provides an ecological slow-release carbon source and its preparation method.

[0053] Step 1: Preliminary pretreatment and cutting of corn stalks, with a diameter screening specification of 0.5 ± 0.2 cm, cleaned and air-dried, to be processed;

[0054] Step 2, take 15 parts by weight of the sample, and the heating rate is 8°C·min -1 Medium and low temperature dry distillation treatment (temperature is 170°C), and then pyrolysis in water for 40min (pyrolysis temperature is 194°C);

[0055] Step 3, cool the sample after the pyrolysis treatment in step 2 to room temperature, dry to constant weight, obtain the basic slow-release carbon source, fix 4 parts by weight of denitrifying bacteria liquid in the basic slow-release carbon source, and obtain the ecological slow-release carbon source. release carbon source.

[0056] The prepared slow-release carbon source is fine and compact, and the structure of cellulose, hemicellulose and lignin is stable. The struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com